Automatic grain selecting and sorting machine

A technology for grading machines and grain seeds, which is applied in the field of machines, can solve the problems that grain selection cannot automatically form graded flow, sand, straw, branches and leaves are not completely removed, and dust and impurities are not completely removed, so as to facilitate long-term storage and save manpower , the effect of not easy to mold and deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

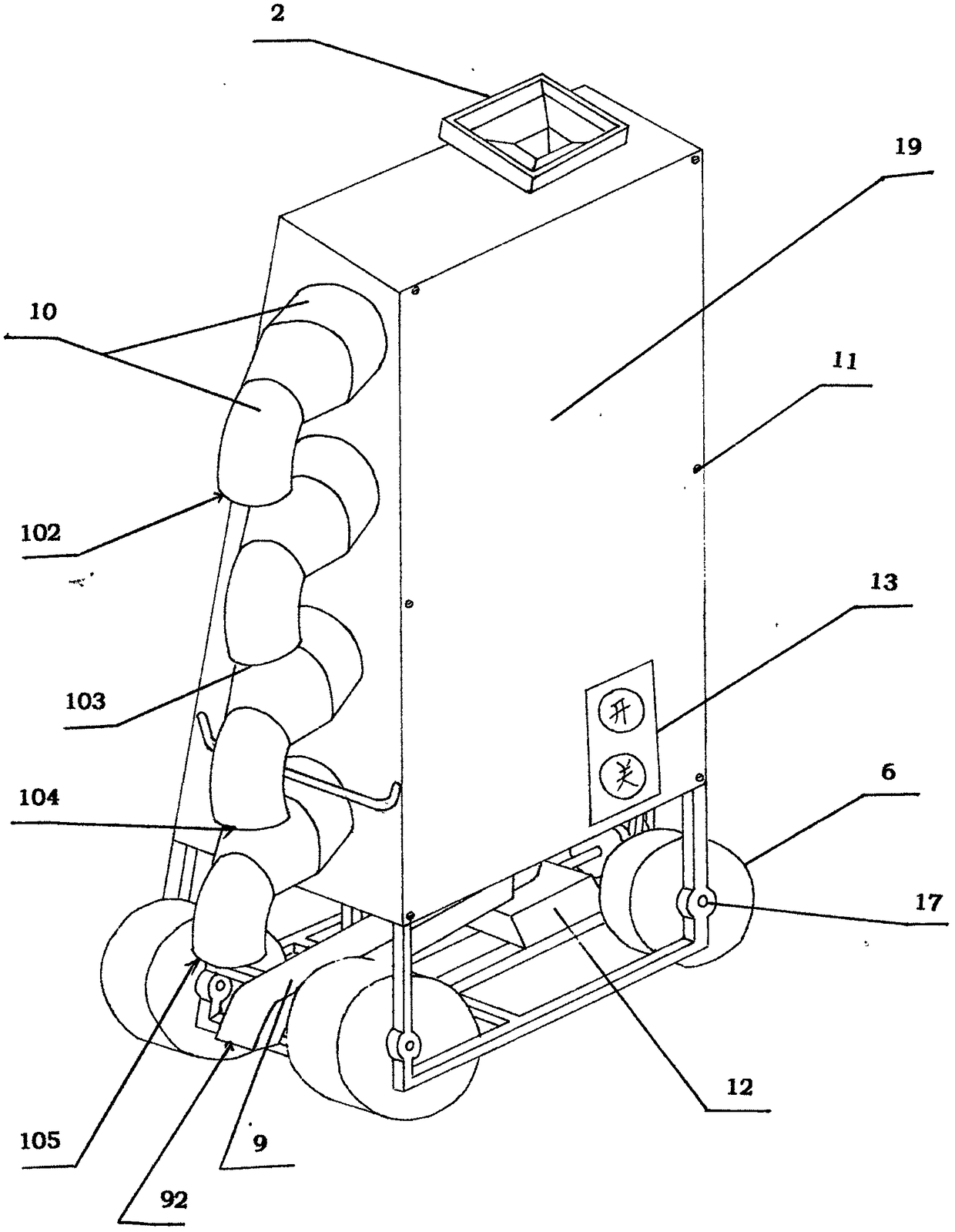

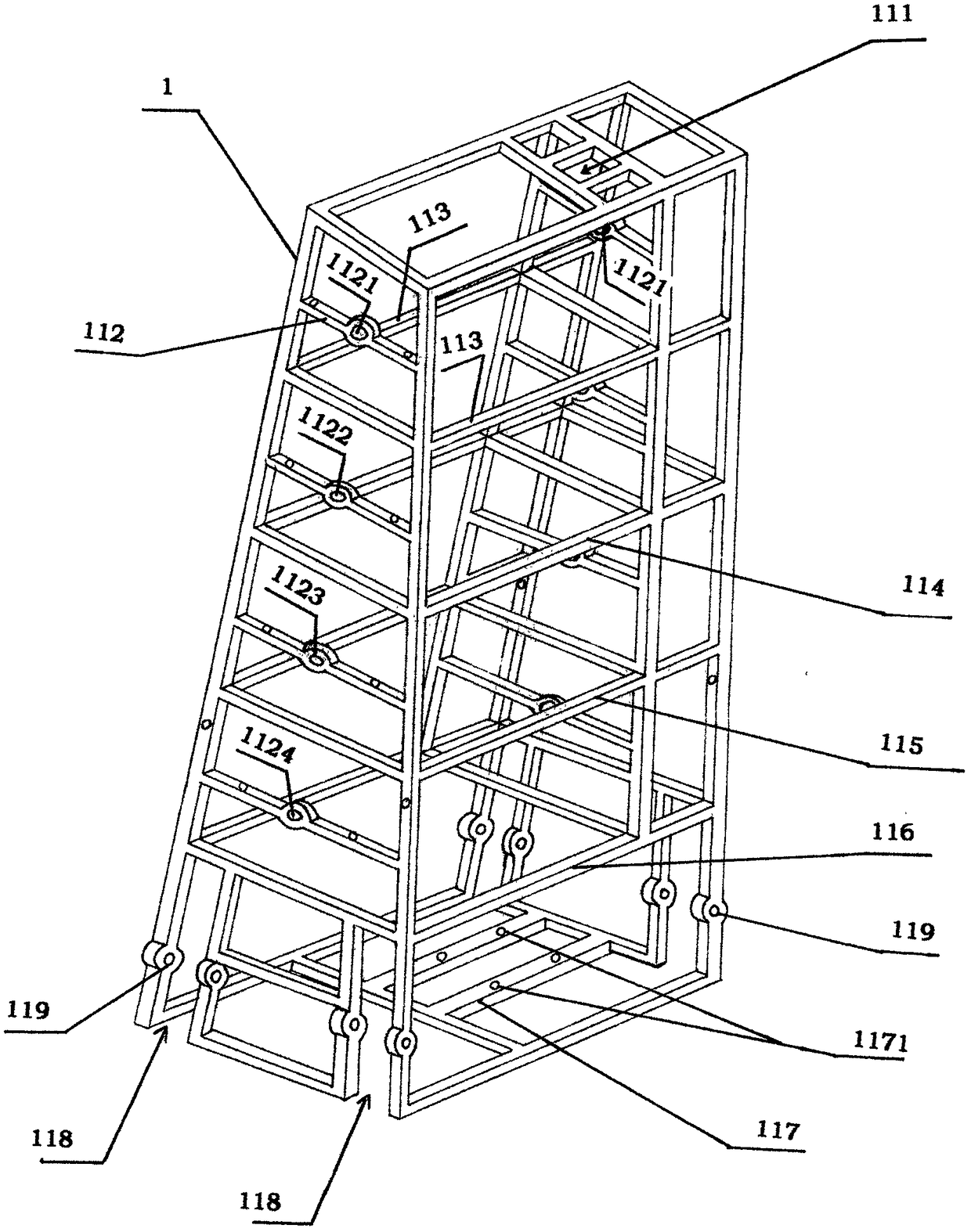

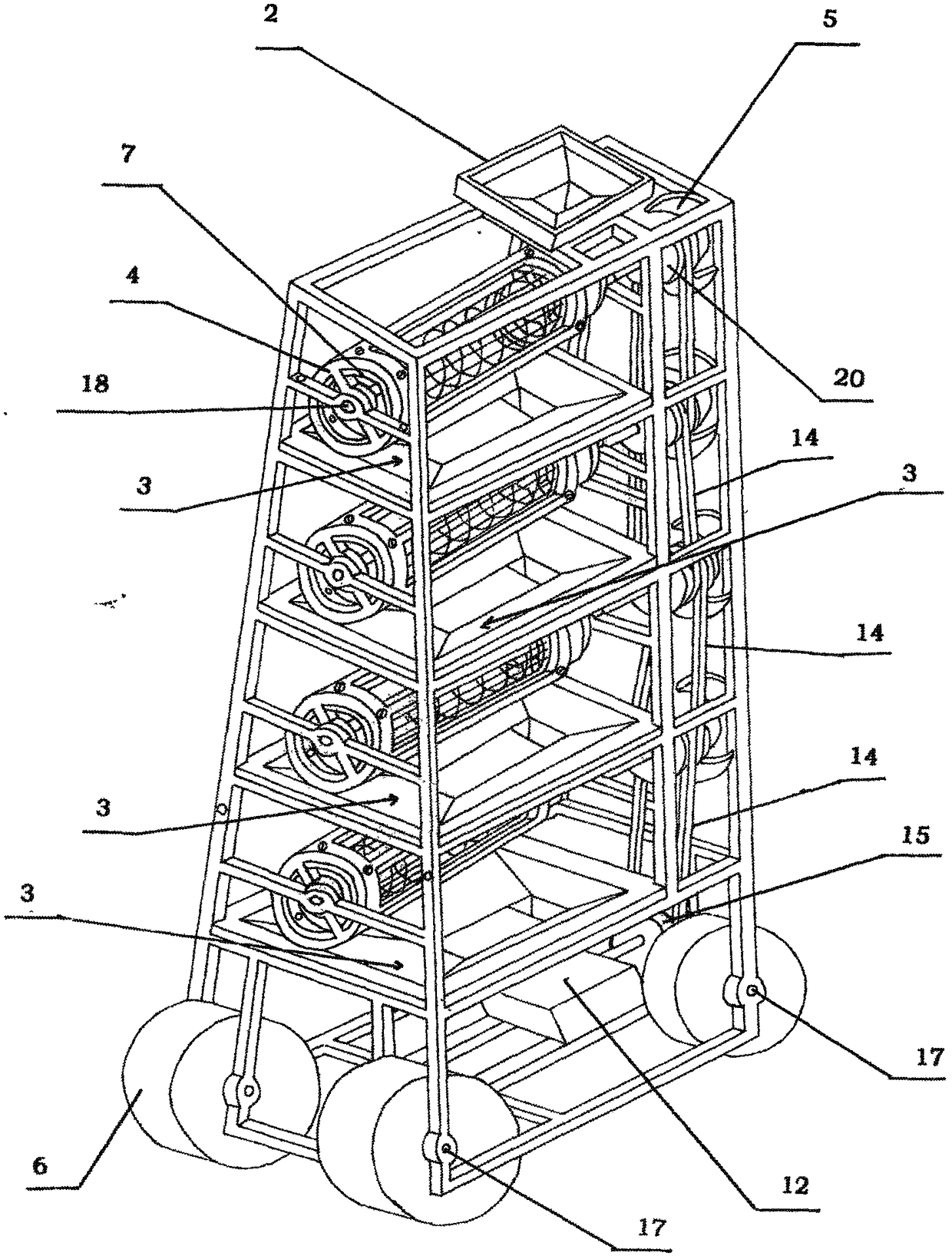

[0021] see Figures 1 to 12As shown, the implementation of the present invention includes that the implementation of the present invention includes a frame body 1, a funnel 2, a drag bucket 3, a rotating body 4, a maple impeller 5, a walking wheel 6, a sieve body 7, a garden bucket 8, a miscellaneous groove 9, an arc Road 10, screw 11, motor 12, switch 13, V-belt 14, motor wheel 15, rotating wheel 16, shaft 17, long shaft 18, casing 19, shaft wheel 20, wrench 21, etc. There are six upper and lower beams, and the upper layer is provided with a square opening 111 for placing the funnel 2; the screen body 7 is formed by connecting the screen 71 with two opposite circular frames 72; the spiral body 4 is formed by two discs 42 opposite to the two The crossbeams 41 are connected together; the screen body 7 is installed in the space provided in the two groups of relative crossbeams 41 provided on the rotating body 4, and the through hole 43 provided by the disc 42 is screwed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com