Patents

Literature

47results about How to "Not easy to mold and deteriorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lithocarpus litseifolius total flavone

InactiveCN101904882AImprove solubilityLow toxicityMetabolism disorderFood preparationEnergy consumptionFlavones

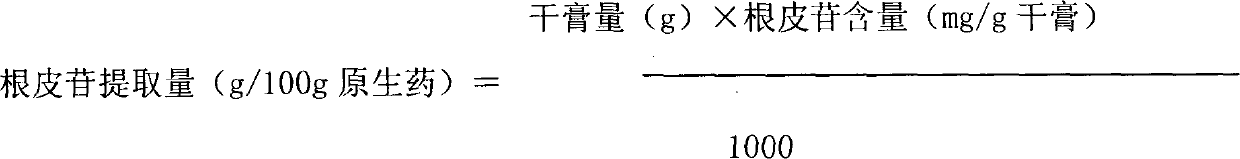

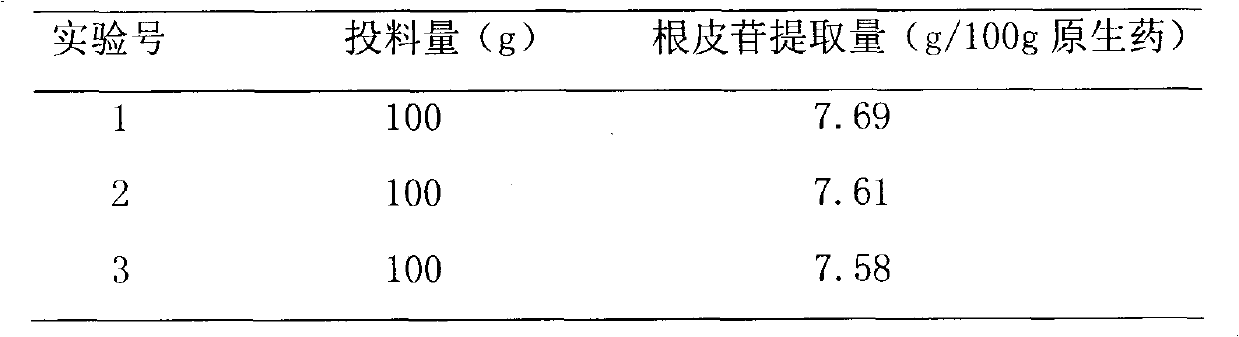

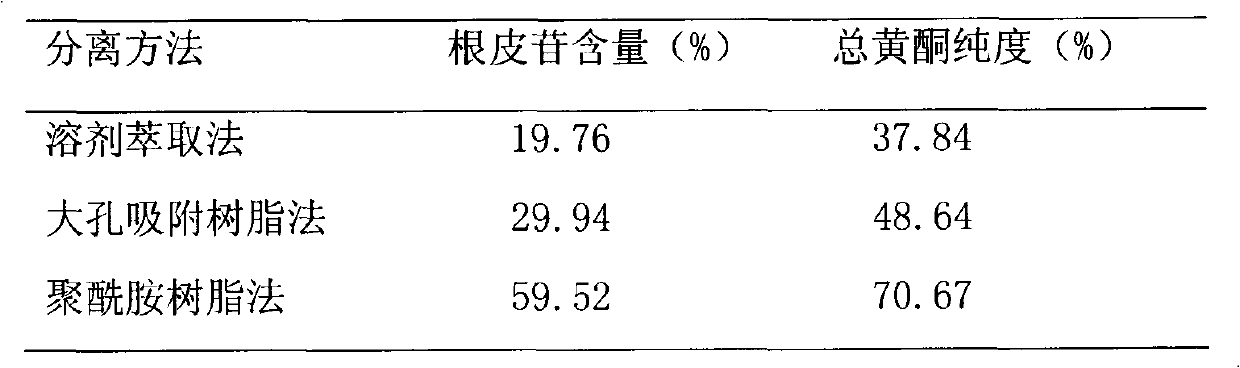

The invention discloses lithocarpus litseifolius total flavone extracted by using plant lithocarpus litseifolius as a raw material to develop a new hypoglycemic medicament, and provides a method for preparing the lithocarpus litseifolius total flavone. The purity of the lithocarpus litseifolius total flavone prepared by the method can reach over 80 percent, the phloridzin content reaches over 65 percent, the process is simple and has low energy consumption, and the technological condition is reasonable, stable and feasible. A hypoglycemic capsule developed by using the lithocarpus litseifolius total flavone can provide a convenient, acceptant and long-term taking oral hypoglycemic preparation for diabetics.

Owner:GUANGXI INST OF CHINESE MEDICINE & PHARMA SCI

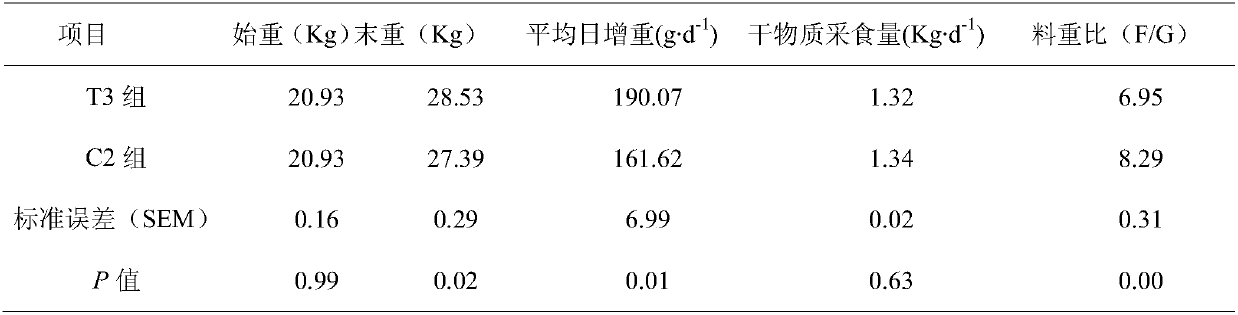

Preparation method and application of pleurotus eryngii bran fermented feed

PendingCN107897506ALow costRealize resource utilizationFood processingAnimal feeding stuffFlavorResource utilization

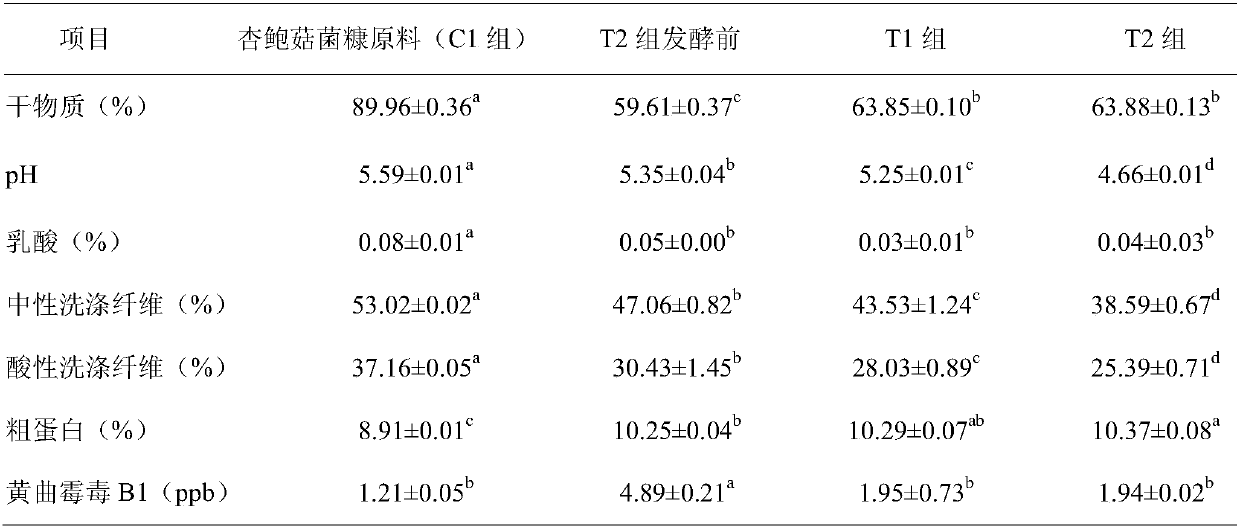

The invention provides a preparation method and application of pleurotus eryngii bran fermented feed. The feed is prepared from pleurotus eryngii brans, bacterial complex, brans, brown sugar and edible salt. According to the preparation method, the fermenting base material containing the bacterial complex, brans, brown sugar, edible salt and pleurotus eryngii brans is adopted, and is subjected toanaerobic fermentation to obtain bran fermenting feed. Compared with pleurotus eryngii brans, the fermented feed has the advantages that the nutritional structure and flavor are remarkably improved; since the pleurotus eryngii brans do not need drying pretreatment, the fermented feed cannot be easily mildewed or go bad, and can be stored for a long time. The method can be used for reducing the cost for transforming pleurotus eryngii brans into fermented feed along with high transformation efficiency, is favorable to realizing large-scale and resource utilization of bacterial brans, and can beapplied to mutton sheep fattening. The raw materials for preparing the pleurotus eryngii bran fermented feed is not affected by seasons, can be supplied all year; and the preparation procedure is simple, can be easily popularized and applied, and has remarkable economic benefit.

Owner:NORTHWEST A & F UNIV

Preparation method for microbial straw micro-storage feeds

InactiveCN103535512AGain weight fastPromote milk productionFood processingAnimal feeding stuffAnimal scienceMicrobial agent

The invention relates to the field of feeds for animal husbandry, and provides a preparation method for microbial straw micro-storage feeds. The method comprises the following steps of (1) activation of a straw fermentation and activation microbial agent; (2) dilution of a strain stock solution; (3) pretreatment of straws; (4) micro-storage of the straws; (5) pit sealing; (6) fermentation management. The feeds prepared by the method are low in cost, and have good benefits, the utilization rate of the straws is increased, the feeding amount of domestic animals is greatly increased, and remarkable economic benefits are created.

Owner:QUANZHOU LUOJIANG MAOYUAN AGRI DEV

Preparing process of botanical hollow enteric hard capsule

InactiveCN1985809ANo side effectsGood for physical and mental healthCapsule deliverySide effectHard Capsule

The present invention discloses the preparation process of botanical hollow enteric capsule. The botanical hollow enteric capsule is prepared with sodium alginate extracted from kelp or Sargasso as material, and through the technological steps of preparing gelatin, preparing sol, debubbling, adhering, converting, purifying, stoving, cutting, etc. It is used in making medicine capsule, and has the advantages of high safety, low cost and no toxic side effect.

Owner:黄族和

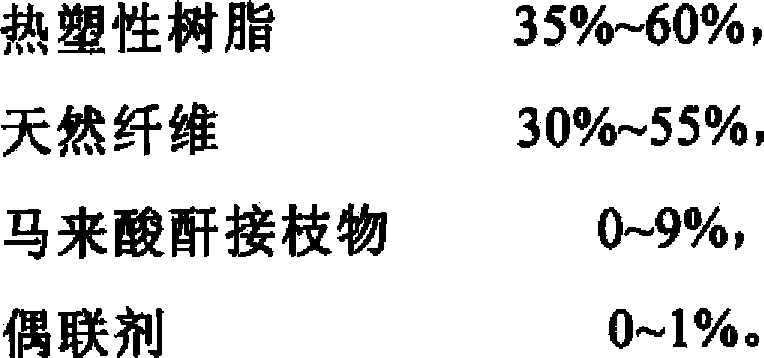

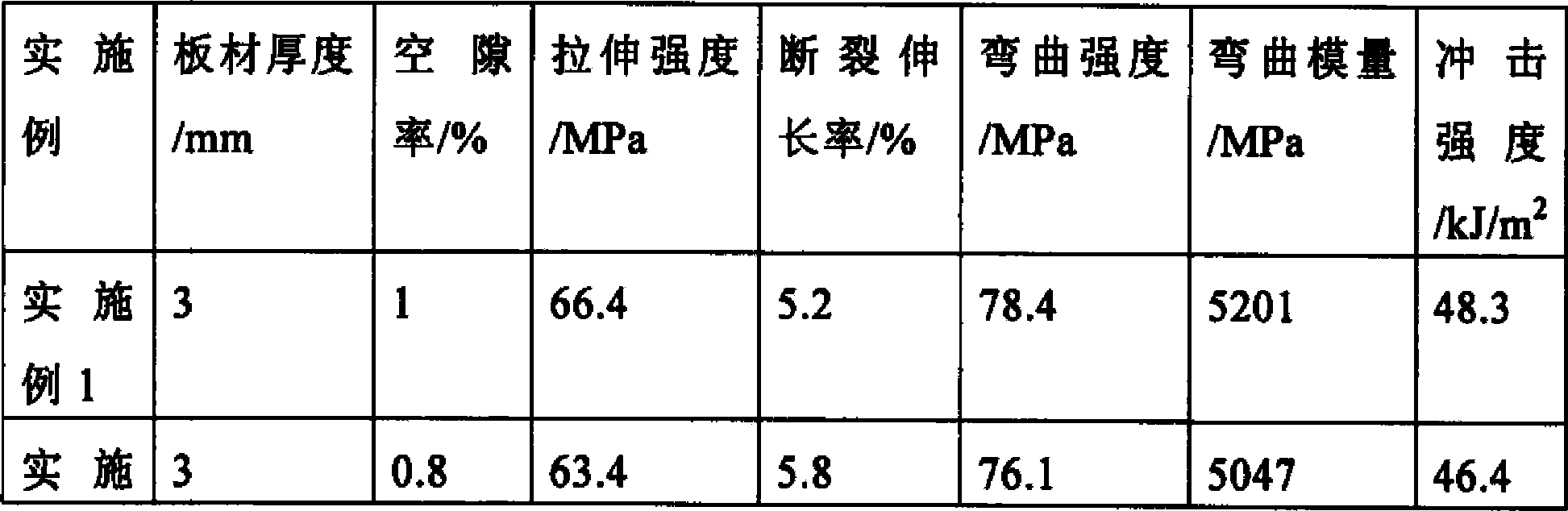

Natural fiber composite board, and manufacturing method and application thereof

InactiveCN103849019AAdjustable longitudinal lengthMeet the length requirementVegetal fibresNatural fiberUltimate tensile strength

The invention relates to a natural fiber composite board and a manufacturing method and application thereof. The natural fiber composite board is prepared from the following raw materials by weight: 35 to 60% of a thermoplastic resin, 30 to 55% of a natural fiber, 0 to 9% of maleic anhydride graft and 0 to 1% of a coupling agent. The procedures consisting of mixing, washing and starching, weaving, desizing and hot pressing are carried out so as to form a natural fiber reinforced thermoplastic resin board which is used for manufacturing of a mobile phone protective shell, an IPAD shell, a musical instrument, a box or a helmet. Compared with the prior art, the natural fiber composite board provided by the invention has the advantages of great strength, stable performance, effectively controllable thickness direction, etc.

Owner:HEFEI GENIUS NEW MATERIALS

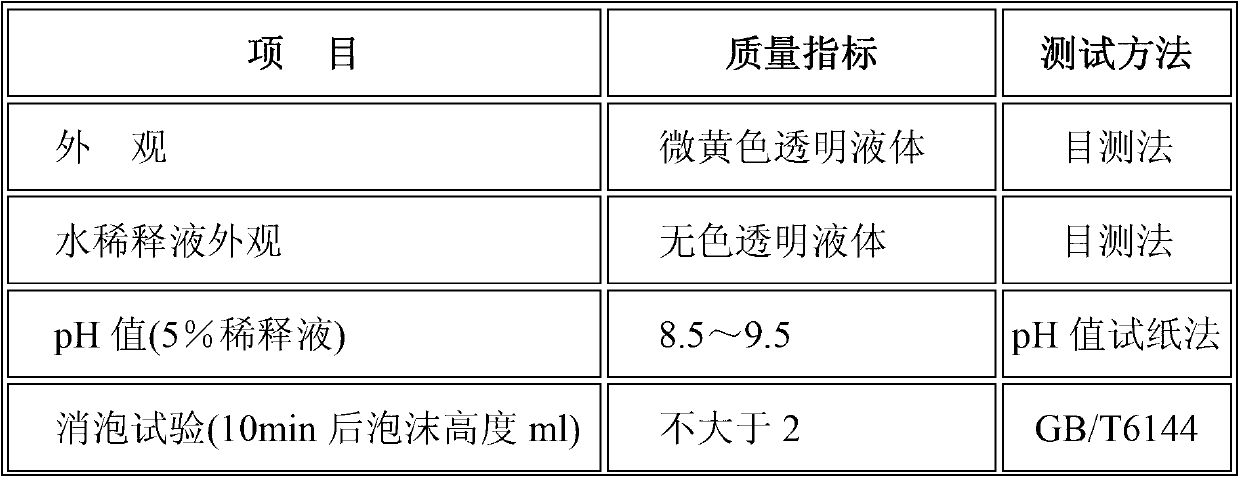

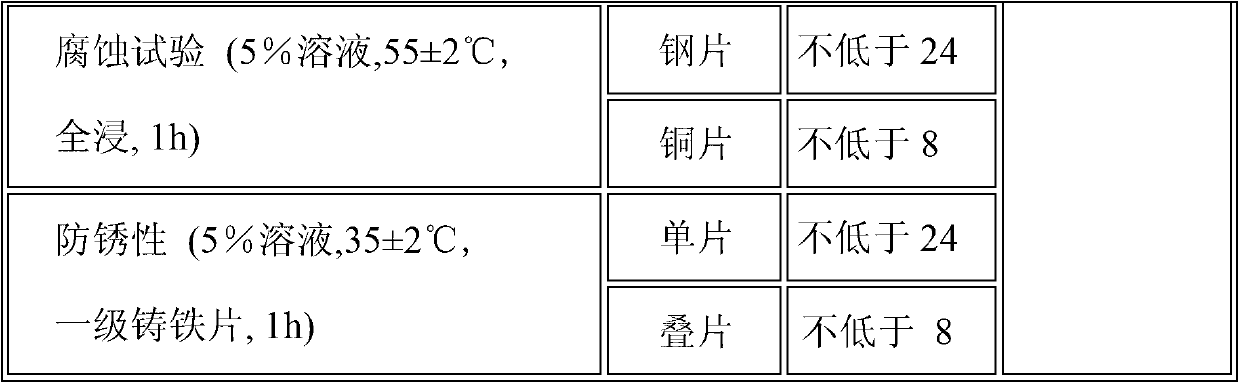

Settleability water base grinding fluid and preparation method thereof

ActiveCN103131331AReduce surface tensionReduce pollutionAqueous dispersionsEthylenediamineWater based

The invention provides settleability water base grinding fluid and a preparation method thereof. The settleability water base grinding fluid comprises, by weight, the following ingredients: 5-20% of settling agents, 25-60% of antirust agents, 15-40% of lubricating agents, 1-3% of sterilizing agents and the balance water. The settling agents are selected from one or more mixtures of polyethylene dichloro ethyl ether tetramethyl ethylenediamine, polyglycerol and ethylene glycol butyl ether (EGBE). The settleability composite grinding fluid has the advantages of being good in settleability, rapid in defoaming, good in antirust effect, long in service life and high in comprehensive performance cost ratio.

Owner:广东恒昌科技润滑油有限公司

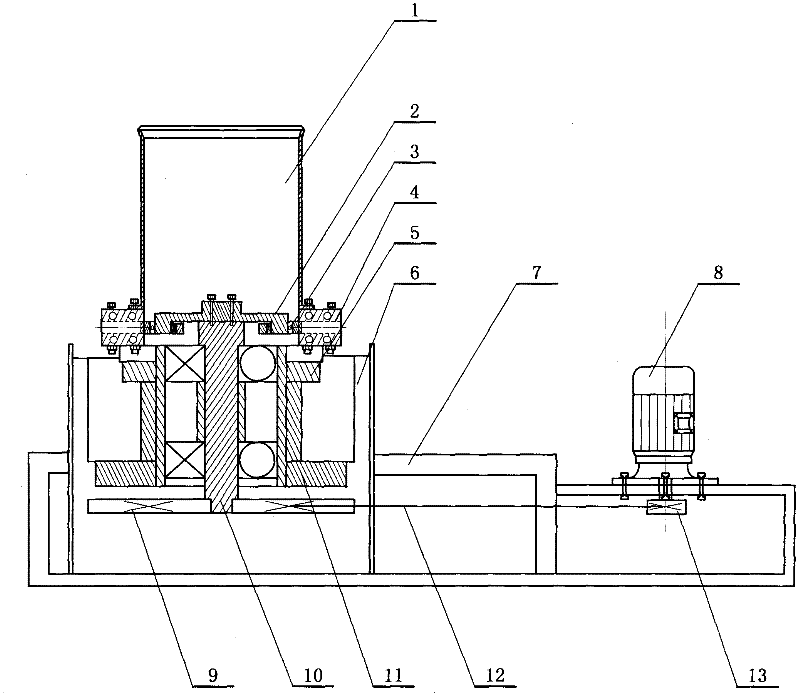

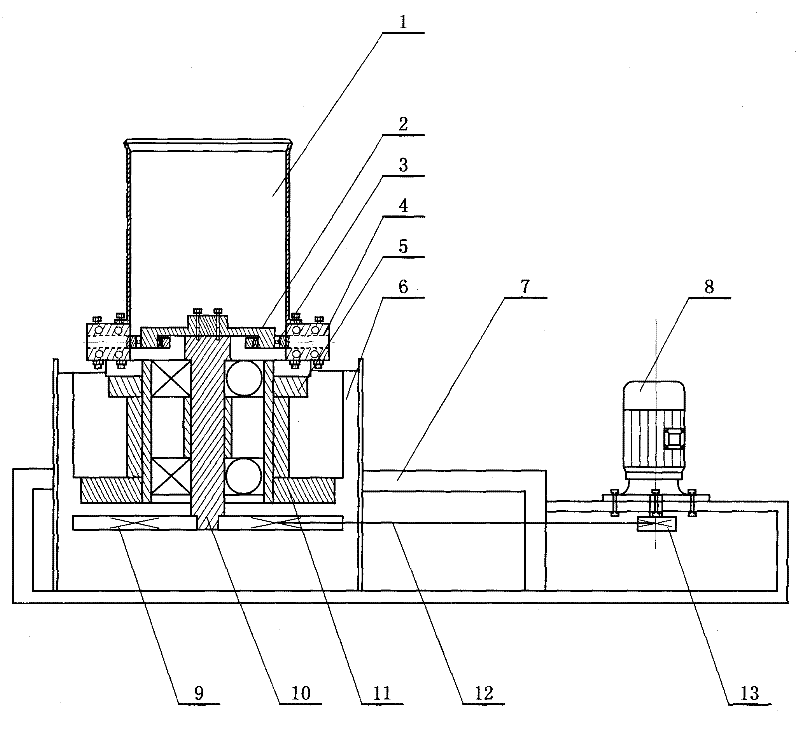

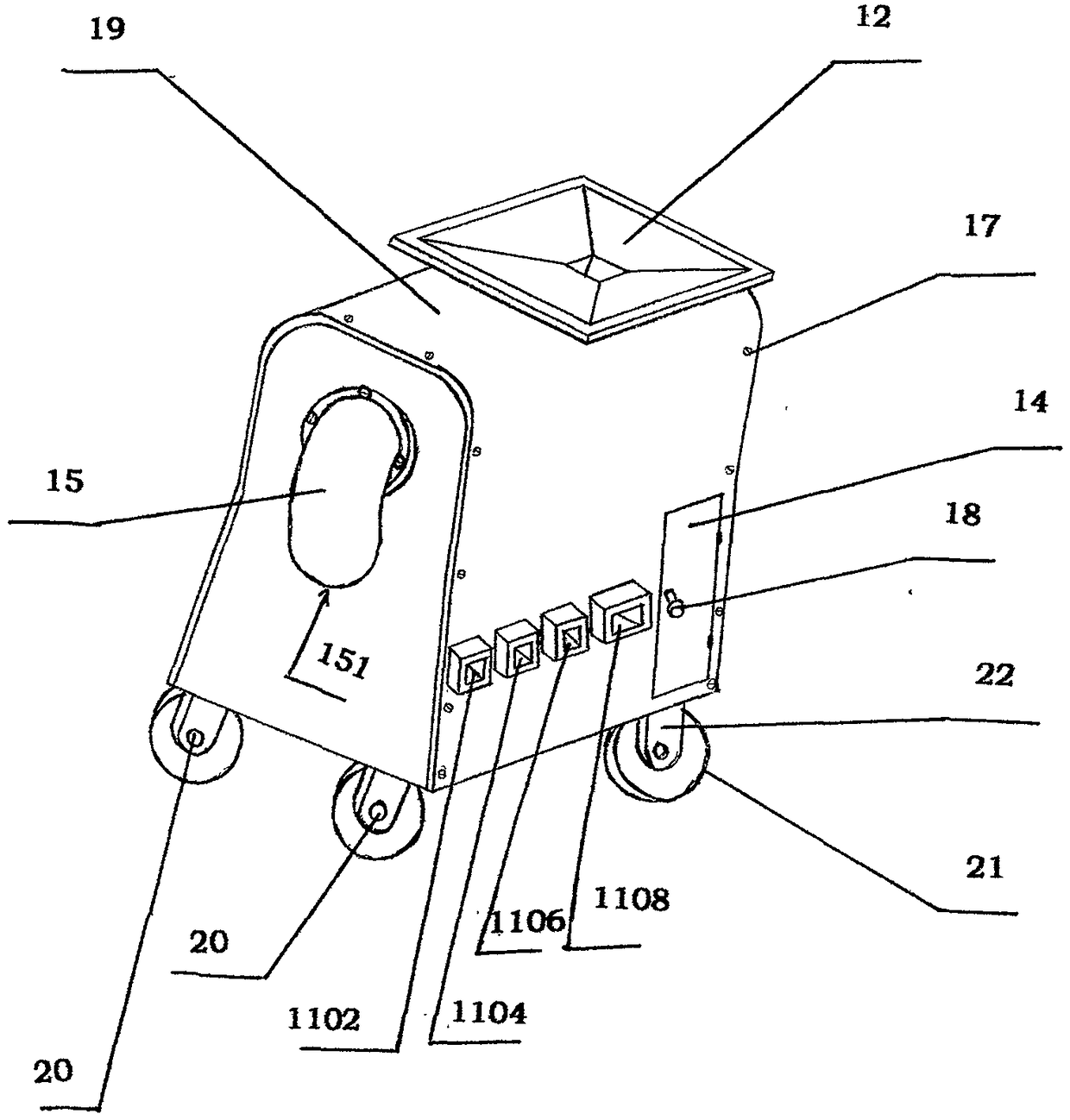

Straw curing and molding machine

The invention relates to a straw curing and molding machine. A circular curing and molding disc is arranged below a feed hopper. The curing and molding disc is provided with an electric heating structure and a molding hole out of circumference. The curing and molding disc is fixed on a base and a frame in the lower part. The frame is provided with a material receiving disc and a central shaft corresponding to the curing and molding disc. A lifting lever and a pinch roller are fixed orderly at the upper end of the central shaft. A large pulley, a belt, a small pulley and a motor are orderly connected at the lower end of the central shaft. The straw curing and molding machine can press the smashed straws to block solid particles and the advantages of wide use range, great fuel value, small ash content and low cost. The block solid particles can replace woods, raw coals and fuel and the straw curing and molding machine is widely used to heating, cooking range, boiler and power generation, reduces the environmental problem brought by straw combustion and saves a large amount of energy cost. And the pressing blocks are not easy to go mouldy and deteriorate and can be stored for a long time.

Owner:徐州市农机技术推广站

Fermentation process of biological fermented feed

InactiveCN106359848APromote digestion and absorptionEnhance physical fitnessAnimal feeding stuffAnti stressBiotechnology

The invention discloses a fermentation process of biological fermented feed. According to the fermentation process, aerobic fermentation and anaerobic fermentation are alternately conducted, generated beneficial strain metabolites and substrate decomposers is rich in kinds, can greatly improve digestion and absorption of gastrointestinal tracts of animals, increase utilization rate of the feed, and is more prone to meet nutritional requirements in each stage of the animal raising process; the generated metabolites and substrate decomposers can further strengthen physiques of animals, improve immunity and anti-stress ability of animals, inhibit growth and adsorption of mycete, adsorb and decompose mycin and toxin, and improve detoxification ability of livers of animals; meanwhile, it is easy to control stability of fermented product through the fermentation process, the fermented product is not prone to go mouldy and go bad and is easy to preserve.

Owner:南京宝辉生物饲料有限公司

Processing method for peacock feathers

The invention discloses a processing method for peacock feathers. According to the processing method, the feathers naturally falling off of peacocks are subjected to rough washing-air drying-ultrasonic washing and drying treatment, a flour aqueous solution can effectively remove small-particle impurities adhering to the surfaces of the feathers, then ultrasonic washing is carried out, the action rate of a sterilization disinfectant on the feathers is increased through the cavitation effect and the mechanical action of ultrasonic waves, so that the permeation effect is enhanced, the efficient sterilizing effect is achieved, in addition, the feathers are hardly influenced, the feather loss cannot be caused, anti-corrosion treatment is carried out by using plant preservative liquid, harmful substances cannot be residual, the treated feathers are harmless to a human body, drying and ultrasonic treatment are carried out, so that the color and luster of the peacock feathers are effectively kept, the peacock feathers are not liable to go mouldy and go bad after being stored for a long time, and the flatness and the glossiness of the feathers processed through the method are obviously improved.

Owner:ANHUI PEACOCK PRINCESS ARTS & CRAFTS CO LTD

Ink stick prepared by replacing animal glue by adopting vegetable glue

The invention discloses an ink stick prepared by replacing animal glue by adopting vegetable glue. The ink stick is prepared from the following raw materials in parts by weight: 25-35 parts of smoke materials, 20-30 parts of carbon black, 50-60 parts of a sizing material, wherein the sizing material is prepared from the following raw materials in parts by weight: 5-7 parts of guar gum, 5-8 parts of flaxseed gum, 1-2 parts of konjaku flour, 1-2 parts of lecithin, 0.1-0.2 part of silver nitrate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of peach gum powder, 0.2-0.4 part of chitosan and right amount of water. the ink stick disclosed by the invention has the advantages that the traditional ink-making gelatin production method is subverted, phytoextracted vegetable glue is adopted completely, adhesive force is stronger, and ink locking effect is better; the smoke materials obtained by compounding a pine tree, pine twigs, xanthium sibiricum and as arum and then incompletely combusting are adopted, so that the prepared ink stick is not only pure in ink color but also aromatic in odor.

Owner:黄太海

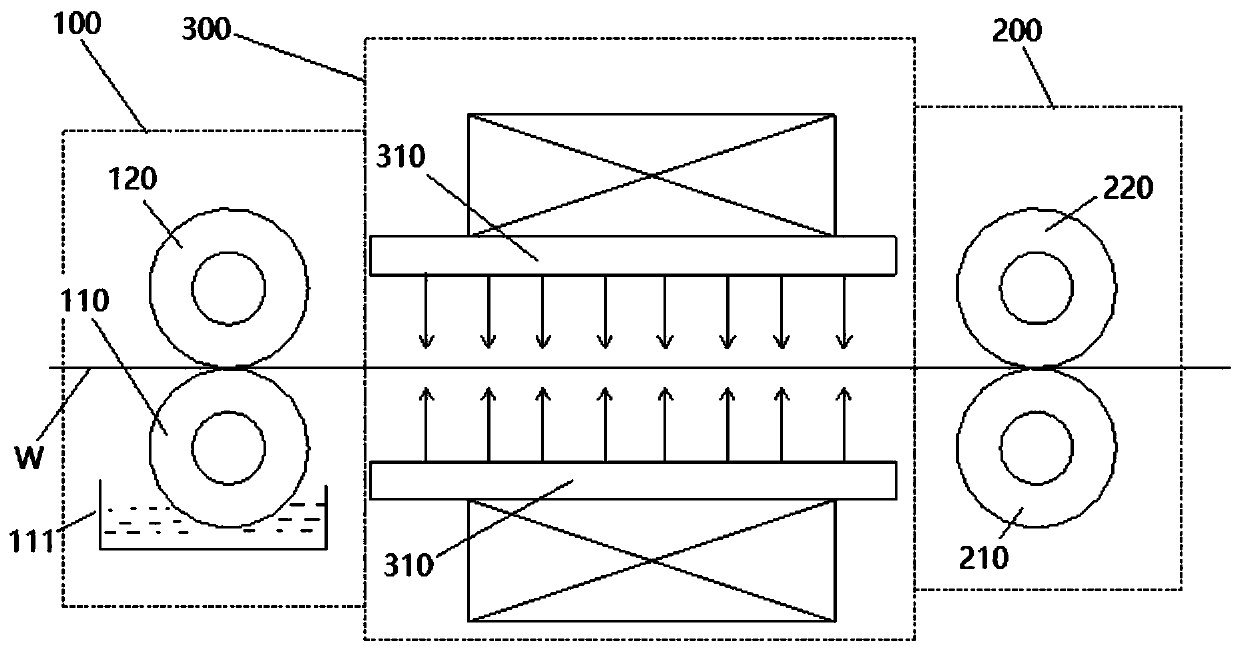

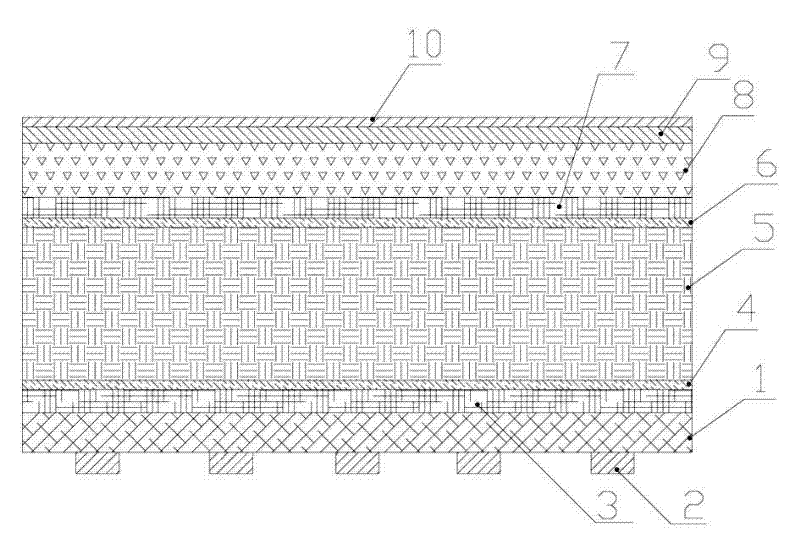

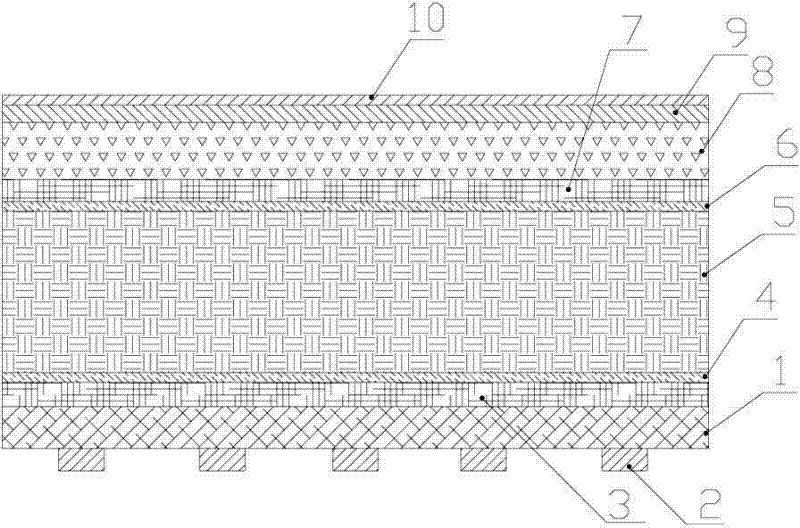

Natural fiber-reinforced thermoplastic composite material prepreg tape, and preparation method and application thereof

ActiveCN104228237ANot easy to mold and deteriorateKeep drySynthetic resin layered productsLaminationPunchingNatural fiber

The invention belongs to the technical field of composite processing, and relates to a natural fiber-reinforced thermoplastic composite material prepreg tape, and a preparation method thereof. The method comprises the following steps of (a) cutting the natural fiber-reinforced thermoplastic composite material prepreg tape and laying; (b) heating the prepreg tape layer into an infrared-ray oven and melting; (c) putting the melted layer into a cold press machine to carry out cold press and cooling to obtain a sheet material; and (d) after the cooling process is finished, cutting the obtained sheet material, punching, polishing, cleaning burs, carrying out precision grinding, spraying paint and applying a surface to obtain a skateboard surface. The prepared natural fiber / thermoplastic resin skateboard surface can be stored for a long time, and after hot press, the natural fibers can be impregnated by the resin thoroughly, so that the material particularly the natural fibers can be kept dry. The natural fibers are not liable to mildew or deteriorate. Products adopted by the invention have no harm to a human body and do not produce adverse reaction.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

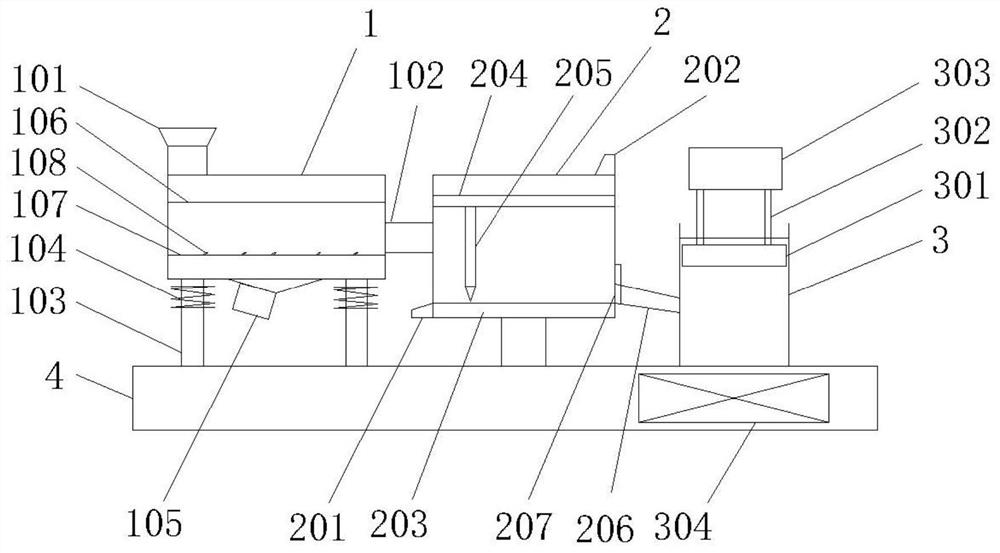

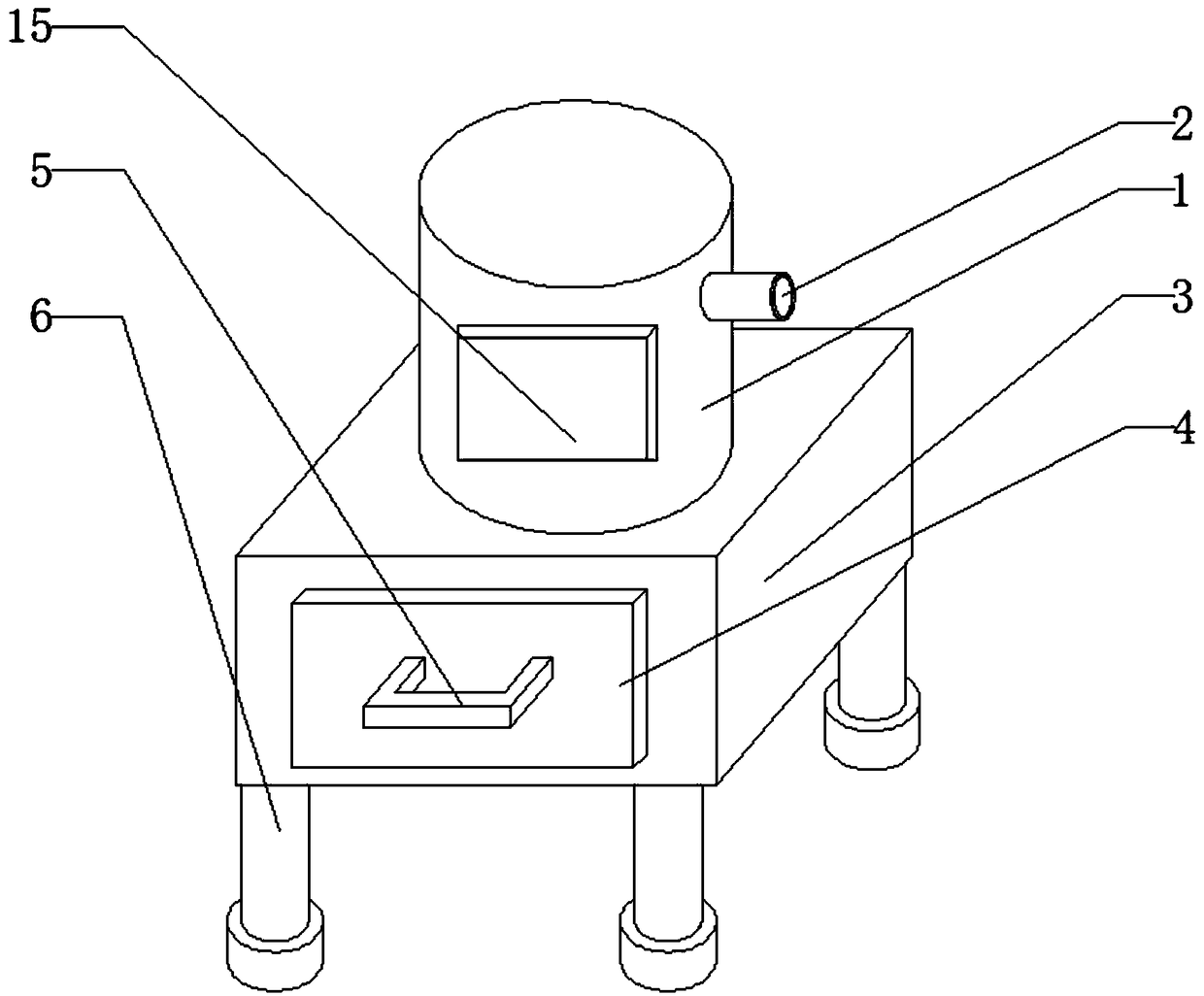

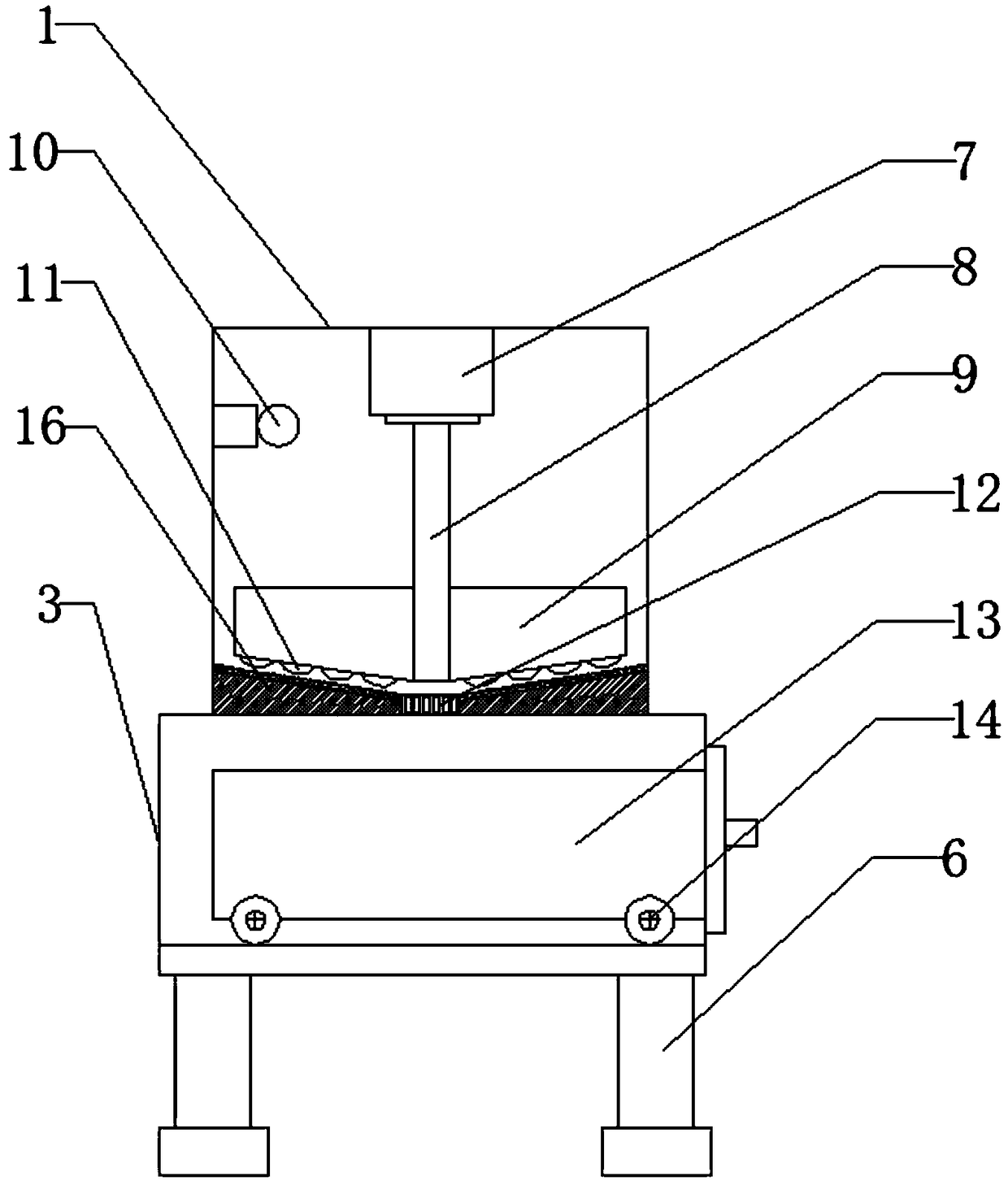

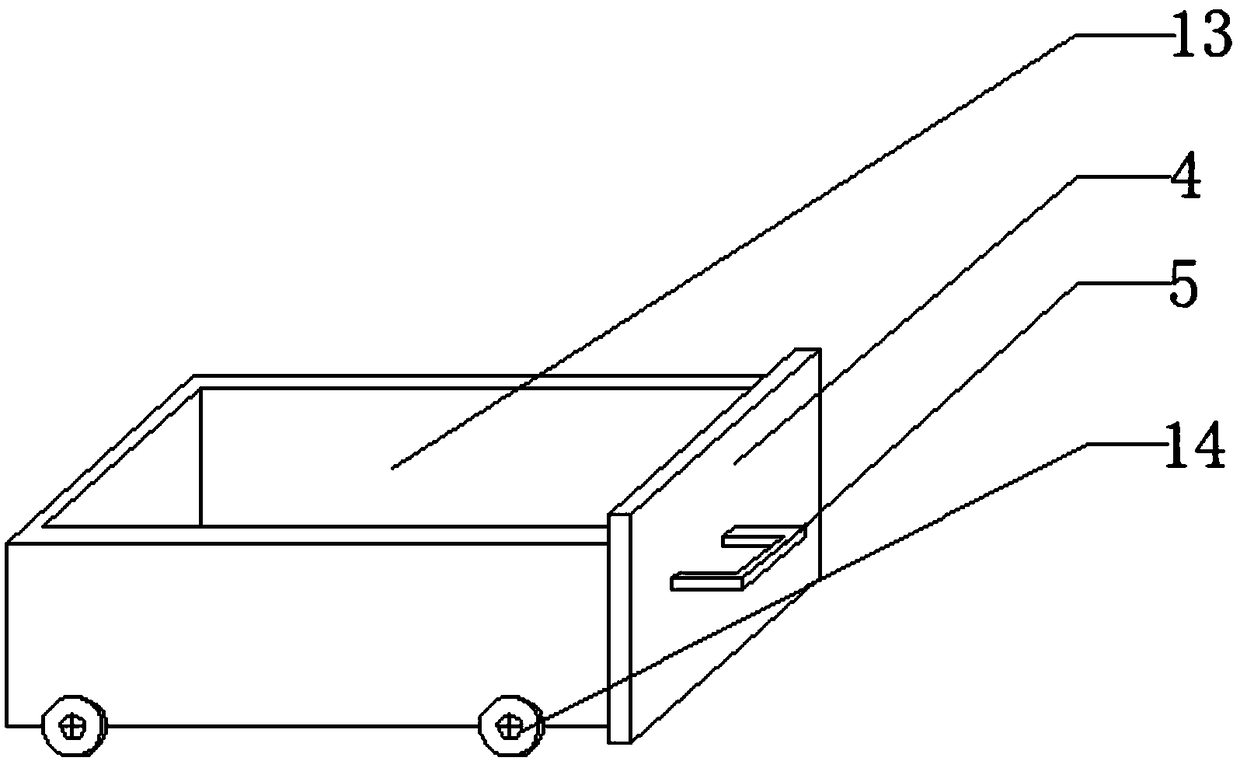

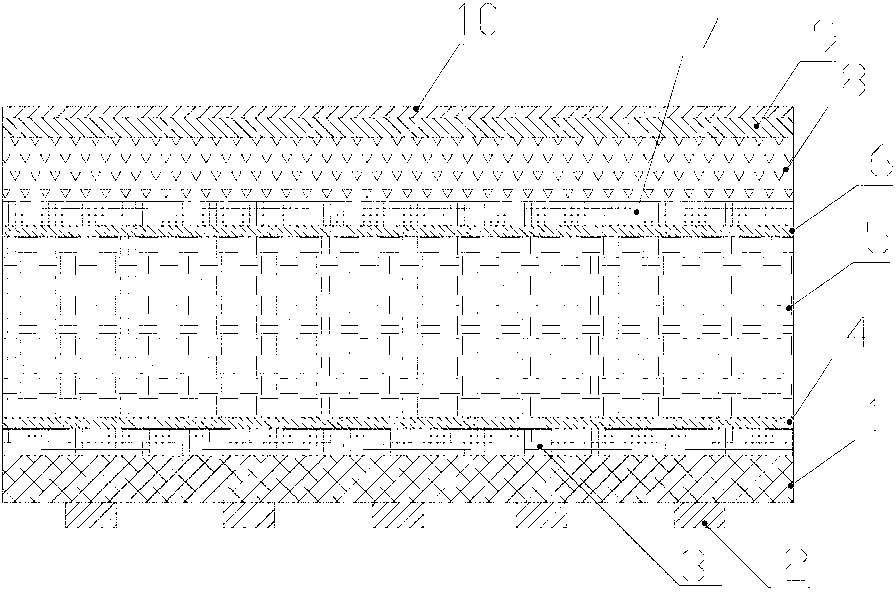

Dust collection material treatment device for furniture production

InactiveCN112060243AExtended shelf lifeNot easy to mold and deteriorateSievingScreeningProcess engineeringSoft materials

The invention relates to the technical field of furniture production, and particularly relates to a dust collection material treatment device for furniture production. The dust collection material treatment device comprises a device base, a screening device, a drying box and a compressing box, wherein the screening device, the drying box and the compressing box are arranged on the device base sideby side. By arranging a first screen and a second screen, large objects and tiny dust in an integrated material can be separated out, only clean and tidy wood chips uniform in size can pass through,inclined blocking strips are additionally arranged above the second screen in the vibration vertical direction, the staying time is prolonged, and the dust filtering effect is improved. The drying boxis arranged before compression, the wood chips are simply dried, water in the wood chips is removed, the wood chips are long in storage life and not prone to going mouldy or going bad, and the deviceis simple and environmentally friendly by utilizing redundant heat and wind power of a workshop. The upper portion of a movable scraper in the drying box is made of a metal plate, a sweeping strip atthe lower portion of the movable scraper is made of a soft material, the movable scraper makes flexible contact with the screens on an exhaust pipeline, and the service life of the scraper is prolonged.

Owner:衡东欧慕定制家私有限公司

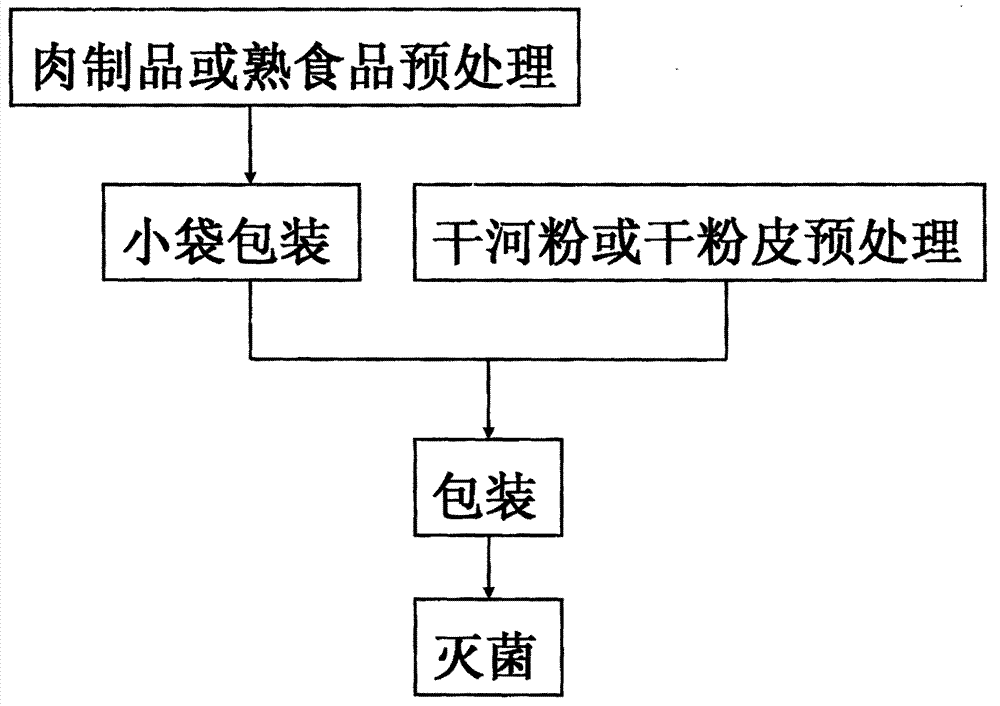

Instant steamed rice roll (steamed vermicelli roll) capable of being steamed in short time

InactiveCN102919623AGuaranteed qualityNot easy to mold and deteriorateFood preparationCooked foodMicrowave sterilization

The invention discloses an instant steamed rice roll (steamed vermicelli roll) capable of being steamed in a short time, and specifically relates to a convenient food prepared by combining two materials including dried rice noodles or dry sheet jellies and meat products or cooked food. The instant steamed rice roll is prepared through cutting a meat products or a cooked food into slices, shreds or dices, sterilizing the obtained product and putting into the sterilized product into a small bag, and sealing the small bag; carrying out sterilization on dried rice noodles or dry sheet jellies, putting the sterilized dried rice noodles or dry sheet jellies and the packaged small meat product or cooked food bag into a big bag together; and carrying out sterilization on the big bag by using a microwave sterilization method so as to obtain the instant steamed rice roll (steamed vermicelli roll), therefore, people also can cook a delicious steamed rice roll (steamed vermicelli roll) at home at ordinary times in person.

Owner:杨荣杰

Litsea cubeba pomace feed and preparation method thereof

InactiveCN107373084ANot easy to mold and deteriorateExtended shelf lifeFood processingAnimal feeding stuffAnimal scienceMildew

The invention belongs to the technical field of feed processing and in particular relates to litsea cubeba pomace feed and a preparation method thereof. The litsea cubeba pomace feed is prepared from the following raw materials in parts by weight: 35 to 50 parts of litsea cubeba pomace, 15 to 20 parts of soybean residues, 10 to 15 parts of glutinous rice flour, 12 to 17 parts of carrots, 13 to 15 parts of sweet potatoes, 2 to 5 parts of bone meal, 5 to 9 parts of oil residue, 1 to 3 parts of table salt and 25 to 35 parts of water. The preparation method of the litsea cubeba pomace feed, provided by the invention, comprises the following steps: mixing and crushing, steaming, carrying out primary drying, grinding, granulating, carrying out secondary drying and packaging. According to the litsea cubeba pomace feed provided by the invention, anti-mildew and antibacterial properties of the litsea cubeba pomace are utilized and the feed prepared by taking the litsea cubeba pomace as a main material does not easily go moldy and go bad and is long in quality guarantee period and high in nutrient value.

Owner:安顺鸿祥绿色产业有限责任公司

Method for fermenting and alcoholizing feed through straw

InactiveCN105211644AImprove palatabilityIncrease feed intakeAnimal feeding stuffPulp and paper industryFermentation starter

The invention provides a method for fermenting and alcoholizing feed through straw. The method includes the steps that straw is selected according to requirements; the straw is cut short and smashed, the length of the straw ranges from 3 cm to 5 cm, and the straw is smashed by a smasher into 4-mesh particles to 10-mesh particles; a fermenting agent is mixed and stirred, and a fermentation preparation and the straw are uniformly mixed; hot water at the temperature of 40-60 DEG C is added into the straw, and the weight ratio of the straw to the hot water is 100:85-100; the straw is contained in a fermentation container, sealed and fermented for over 5 days in a sealed mode.

Owner:杨长有

Method for producing ink paste by adopting traditional ink as raw material and wall-breaking technology

The invention discloses a method for producing an ink paste by adopting traditional ink as a raw material and a wall-breaking technology. The traditional ink raw material is adopted as the basic raw material, the wall-breaking technology is adopted to break walls of raw material particle molecules into microparticles, so that particles reach 1200 meshes or more, and then the microparticles are uniformly dispersed and mixed with plant gelatin or animal gelatin to form black paste. Temperature-difference wall-breaking-ultramicro-pulverization is adopted to decompose and pulverize pine soot, lamp black and paint soot, so as to reduce the particle size and break fusion among the particles, so that the circularity of the particles is improved, an effect that the ink paste diffuses in Chinese art paper is improved, the ink color is more uniform, and an ink painting has rich layers. The ink paste prepared through the method provided by the invention has better stability and longer storage time, can be blended with water for use, is adjustable in intensity, and fundamentally overcomes the defects that preservative residues in ink damage the Chinese art paper and the like.

Owner:黄太海

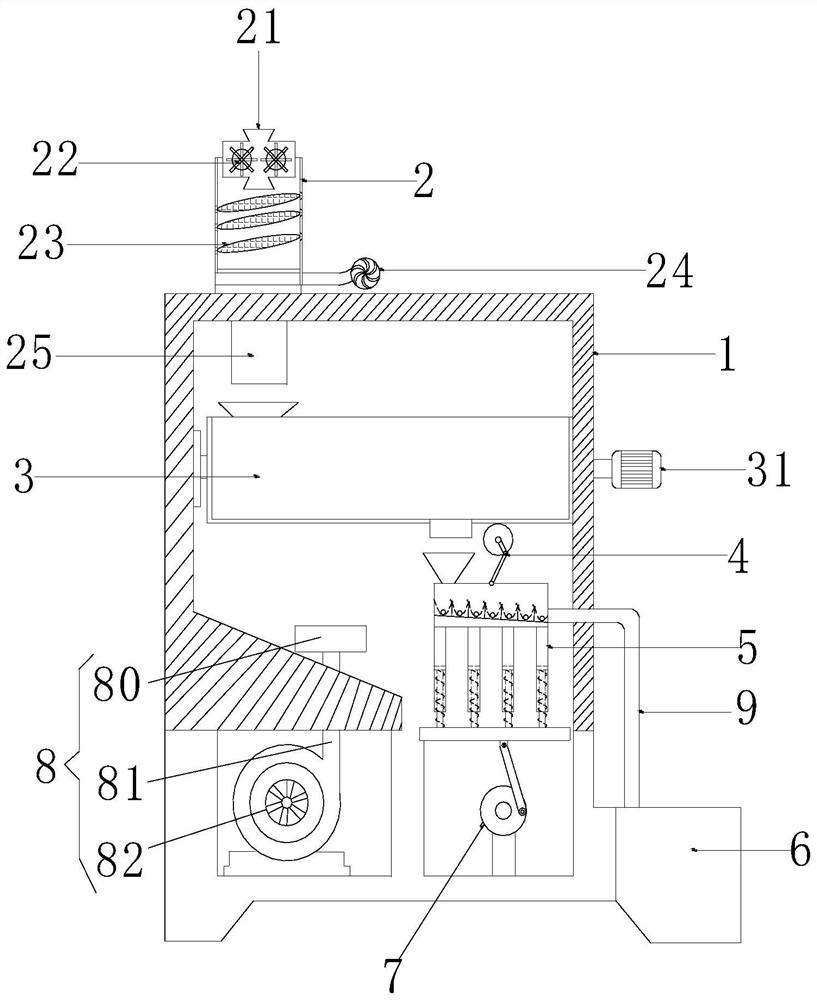

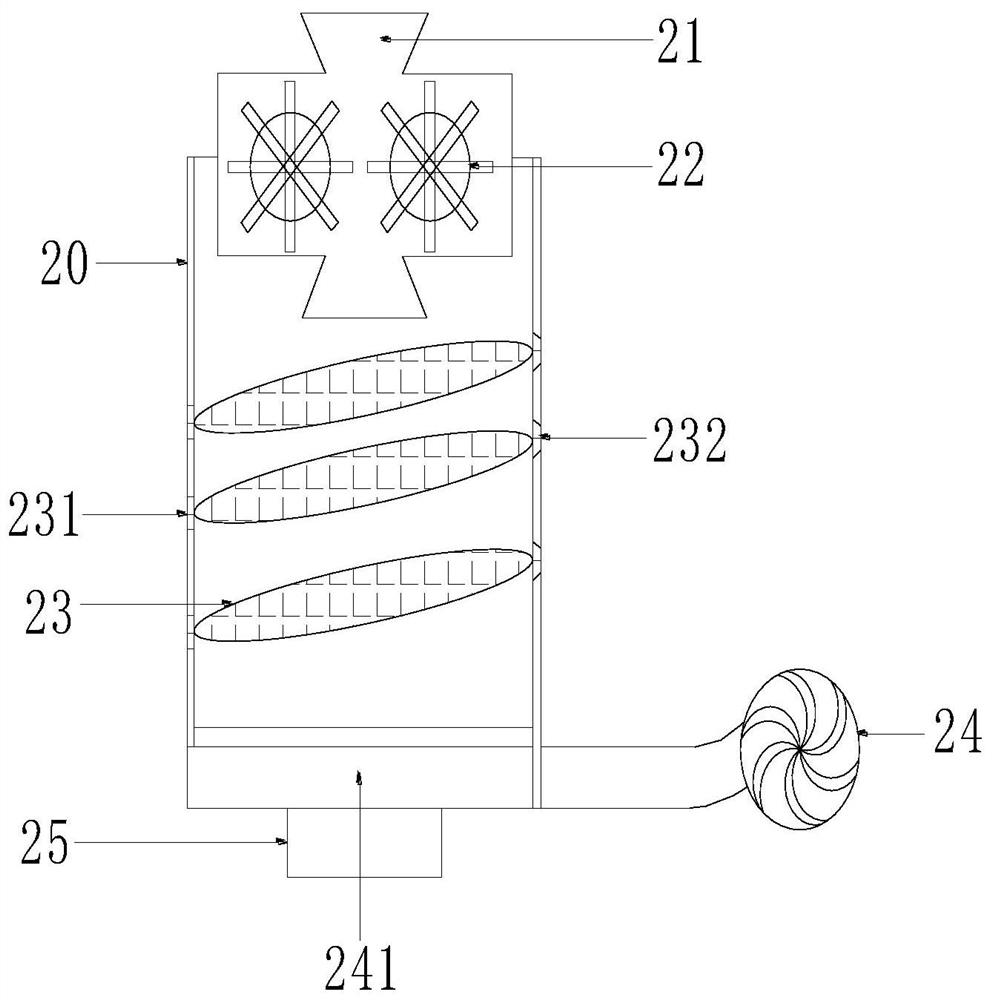

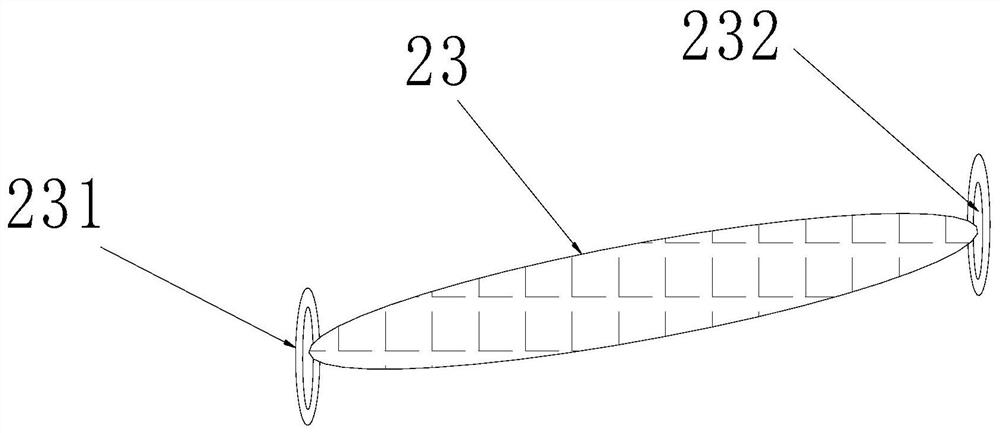

Rotary reciprocating type tea screening and processing device

InactiveCN112931639AImprove screening accuracySimple structureSievingPre-extraction tea treatmentTea leafElectrical and Electronics engineering

The invention provides a rotary reciprocating type tea screening and processing device. Comprising a box body, a screening box, a stir-frying cylinder, a rotary reciprocating mechanism, a drying device and a collecting box. The screening and processing device processes and screens tea leaves in a multi-layer screen mode, screens are connected with bearings and can swing along with left-right swing of gears, three screen layers are arranged in the screening and processing device, the caliber of the upper-layer screen is larger than that of the lower-layer screen, and the inclination angle of the screens is 30 degrees; The screening precision is greatly improved; the rotary reciprocating mechanism drives the whole drying box to reciprocate up and down. When the coil is intermittently electrified, the coil and the bearing rod form an electromagnet, the electromagnet and the magnet block repel each other in magnetic force, and when the electromagnet is electrified, the electromagnet drives the magnet block to move upwards and can pull the tea turning block, so that the tea turning block turns tea leaves; the linkage of a mechanical structure is matched with the electromagnet to dry the cleaned tea leaves, uncertain factors during natural airing cannot be generated, the moisture of the tea leaves is treated in time, and the tea leaves are not prone to mildewing and deterioration.

Owner:金寨县君茗缘有机茶开发有限公司

Processing method of prepared rehmannia root

InactiveCN108619303ANot easy to breedShort wine stew timePlant ingredientsRadix Rehmanniae PreparataRehmannia glutinosa

The invention provides a processing method of prepared rehmannia root. The method comprises the following steps: a, slicing dried rehamnnia root, drying the dried rehamnnia root for 2 to 3 hours at 50to 70 DEG C, putting the dried rehamnnia root into a turning steamer while the dried rehamnnia root is hot, adding yellow wine, and ensuring that 30 to 50kg of yellow wine is used for each 100kg of dried rehamnnia root; performing covered moistening for 0.5 to 1 hour, and performing steaming with steam; b, performing insulation stewing for 0.5 to 1 hour after steam is closed, and then taking outthe dried rehamnnia root; c, performing drying at 50 to 70 DEG C through a through flow oven, ensuring that the drying thickness is 5 to 10cm, and continuously drying the dried rehamnnia root for 40 to 50 hours, so as to obtain the prepared rehmannia root. The method has the advantages that the time for stewing with wine is short, the dried rehamnnia root is easy to be thoroughly stewed, and energy is saved; the adoption of the turning steamer is beneficial to sufficient steaming of prepared rehmannia root medical herb in pieces, and the purpose of processing is achieved; through the adoptionof the through flow oven, the drying speed is high, the drying process is not affected by weather, bacterium is not easy to breed, the prepared rehmannia root is not easy to go mouldy and go bad, thelabor intensity is small, and the method is beneficial to industrial mass production. The whole processing technical period is short and is approximately 2 to 3 days. The technology is stable, the content of effective components is high, and the method is suitable for industrial mass production.

Owner:SICHUAN NEAUTUS TRADITIONAL CHINESE MEDICINE

Method for preparing ink by adopting vegetable gelatin to replace animal gelatin

The invention discloses a method for preparing ink by adopting vegetable gelatin to replace animal gelatin, comprising the following steps: uniformly mixing the vegetable gelatin with a moderate amount of water, mixing and heating to 70-80 DEG C, preserving heat for 1-3 hours, adding other raw materials except for coconut shell charcoal antibacterial powder, using a three-roll grinder to grind 3-5 times, adding the coconut shell charcoal antibacterial powder and a moderate amount of boiling water, and mixing uniformly to obtain the product. According to the method disclosed by the invention, as the vegetable gelatin is adopted to replace the animal gelatin, risks caused by diseases of animals itself are avoided fundamentally, defects of preservative residues, animal pharmaceutical residues, heavy metal residues and the like of the animal gelatin are overcome. As the coconut shell charcoal antibacterial powder is adopted as preservative, the ink prepared by the preparation method disclosed by the invention has the advantages of naturalness, no harm, long-lasting effect and good stability.

Owner:黄太海

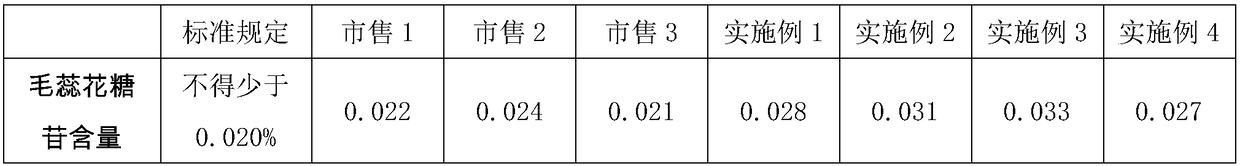

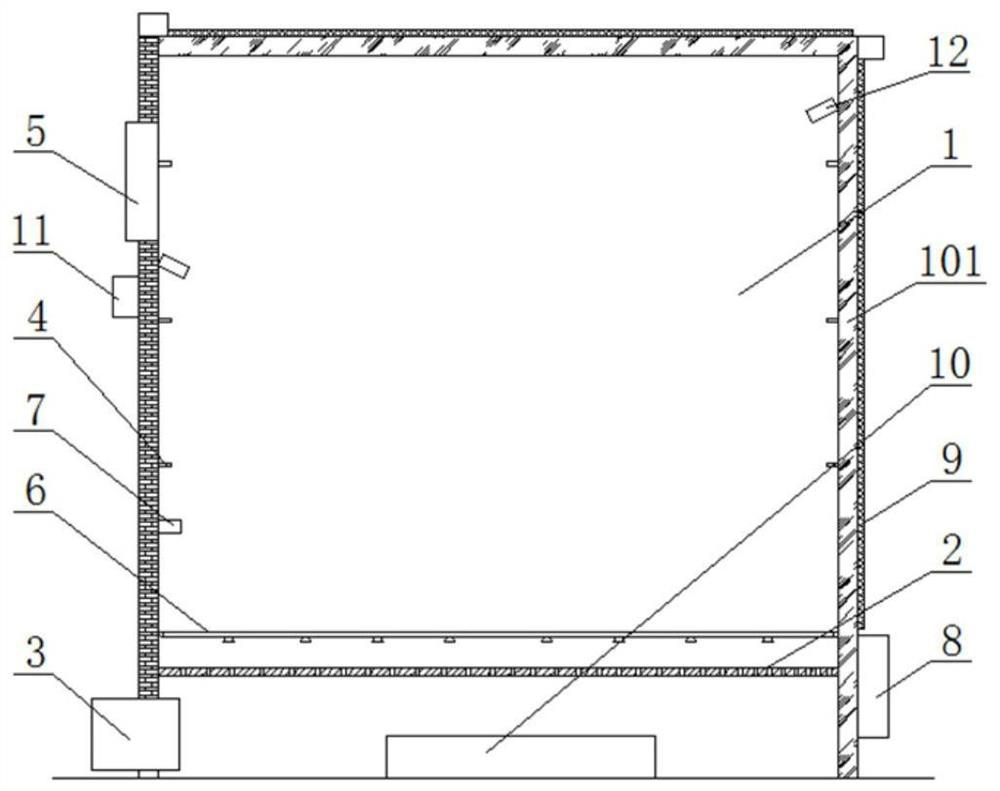

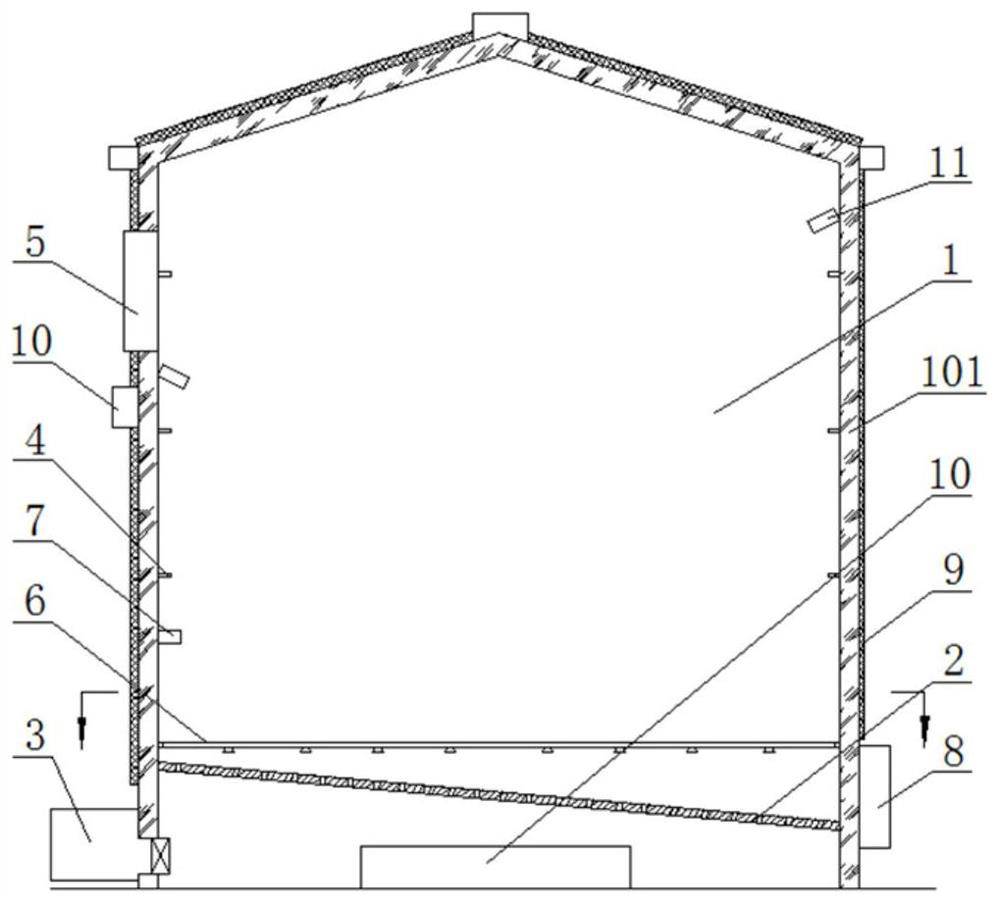

Vitrification sun-curing room for heating cigarette tobacco leaf raw materials for modulation and modulation method

PendingCN112006320AImprove drying qualityRich demandTobacco preparationTemperature controlEngineering

The invention discloses a vitrification sun-curing room for heating cigarette tobacco leaf raw materials for modulation and a modulation method. A heat insulation plate of the sun-curing room is arranged at the bottom of the tobacco sun-curing room, and a hot-air blower and temperature control equipment are arranged below the heat insulation plate. A humidifying and atomizing machine is arranged above the heat insulation plate, the tobacco sun-curing room is internally equipped with an airing rack, a ventilation and dehumidification device communicates the inside and outside, a probe of a temperature and humidity detection device is arranged on the inner side wall and / or the top of the tobacco sun-curing room and electrically connected with the input end of a controller, the top wall and / or at least the sunny side wall of the tobacco sun-curing room are / is provided with light-permeable faces and electric sunshade nets, and the controller is electrically connected with an air heater, the ventilation and dehumidification device, the humidifying and atomizing machine, the electric sunshade nets and the temperature control equipment. The method comprises the steps of tobacco penetrating and shelving, withering and yellowing, color fixing and killing-out. The closed light-permeable tobacco leaf sun-curing room and the control instrument are adopted to be matched with corresponding equipment to control the modulation process, intelligent and precise control over sun-curing is achieved, the modulated tobacco leaves are guaranteed to be uniform in color and stable in quality, and raw materials of various styles are provided for heating non-burning cigarettes.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Fungus fermentation tea leaf powder seasoning making method

InactiveCN109077290ALong storage timeNot easy to mold and deteriorateFood preservationFood ingredient as flavour affecting agentBlack teaCrusher

The invention discloses a fungus fermentation tea leaf powder seasoning making method and relates to the technical field of tea leaf processing. The method is characterized by including following steps: (1), pretreating: washing picked black tea leaves clean, dehydrating, rolling, performing pile fermentation, drying, crushing into powder, grinding aired tea leaves into powder (water content of the powder is less than or equal to 3%, and mesh number of the powder is greater than or equal to 20); (2), treating a sample: putting the powder into water at temperature of 30 DEG C and sterilized athigh temperature for soaking for 4-6h; (3), using beneficial bacteria for fermentation: adding 0.25% of eurotium cristatum (Jinhua fungus) and 0.15% of tea leaf endogenous enzyme, and controlling temperature at 30-35 DEG C for fermentation; (4), filtering: using a funnel to filter fermentation residue; (5), spray-drying tea leaf powder after being filtered, and frying; (6), crushing into powder: using a powder crusher to grind fried powder into powder at high speed within short time; (7), collecting the powder, and packing. Eurotium cristatum is adopted as a fermentation strain, so that the method is unique; obtained black tea powder seasoning is fragrant, refreshing, long in storage time and less prone to mildewing and going bad, has special fragrance and is a high-quality product for household seasoning indeed.

Owner:贵州岚宇茶业有限公司

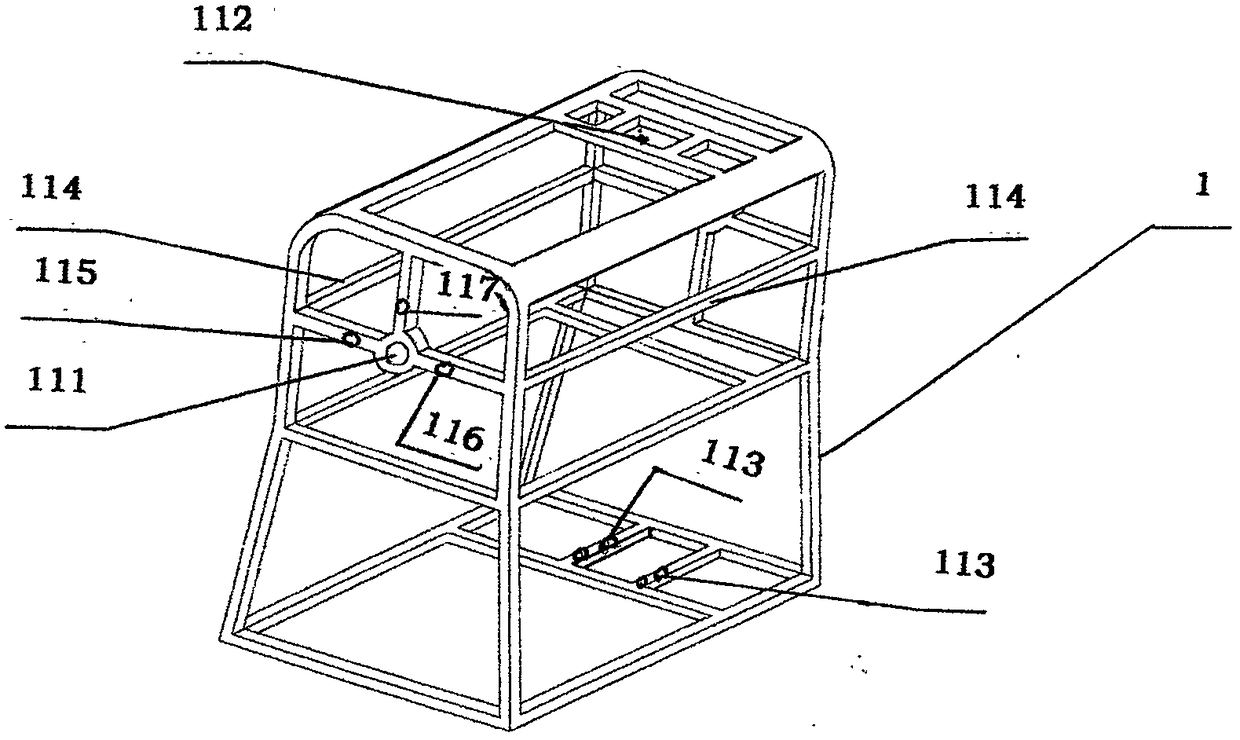

Automatic grading machine for removing impurities in grain seeds

PendingCN108435568AImprove cleanlinessNot easy to mold and deteriorateSievingGas current separationRapeseedEngineering

The invention discloses an automatic grading machine for removing impurities in grain seeds. The automatic grading machine comprises a machine body, a rotary body, a rotary body shaft, an opened sleeve, a screen, a maple leaf wheel, a shaft wheel, a rectangular belt, an electric motor, a motor wheel, a grading box, a funnel, a door, an impurity barrel, a rotary wheel, a threaded rod, a puling handle, a shell, a small shaft, walking wheels, a universal rack and the like; the rotary body is provided with a shaft hole, and the part, which penetrates through the shaft hole, of the rotary body shaft is provided with the maple leaf wheel and the shaft wheel; the rotary shaft penetrates through a corresponding shaft hole formed in the machine body to be assembled; the automatic grading machine isapplicable to one-step screening, impurity removing and grading of wheat, rice, beans, corns, broomcorn, mung beans, peanuts, rapeseeds and other particle seeds, dried fruits and grains; cleanness isgood; long-term storage is facilitated; molding and deterioration do not happen easily; and the automatic grading machine is an indispensable ideal device for agriculture, and is safe, reliable, lowin cost, long in service life, convenient, rapid, low in power consumption, low in noise, labor-saving, large in market, durable, stable in performance and accordant with mechanical principle.

Owner:李国强 +2

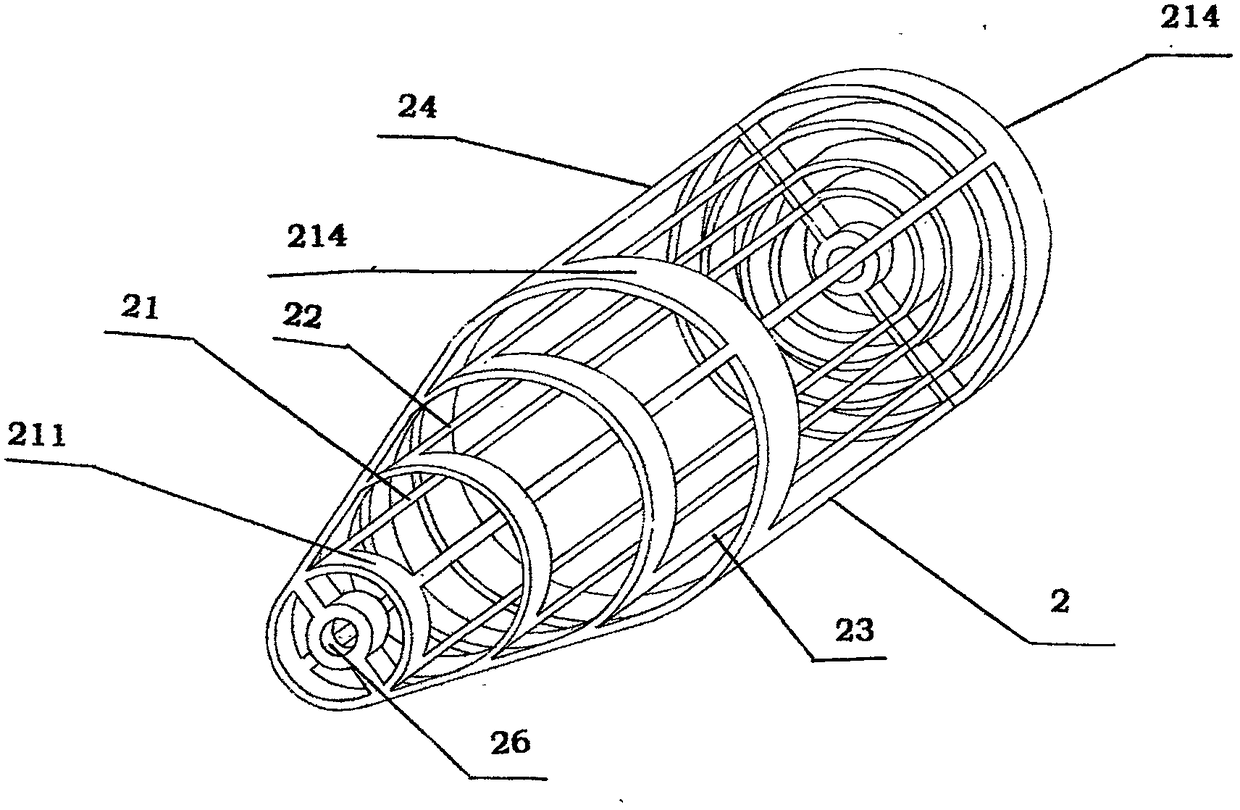

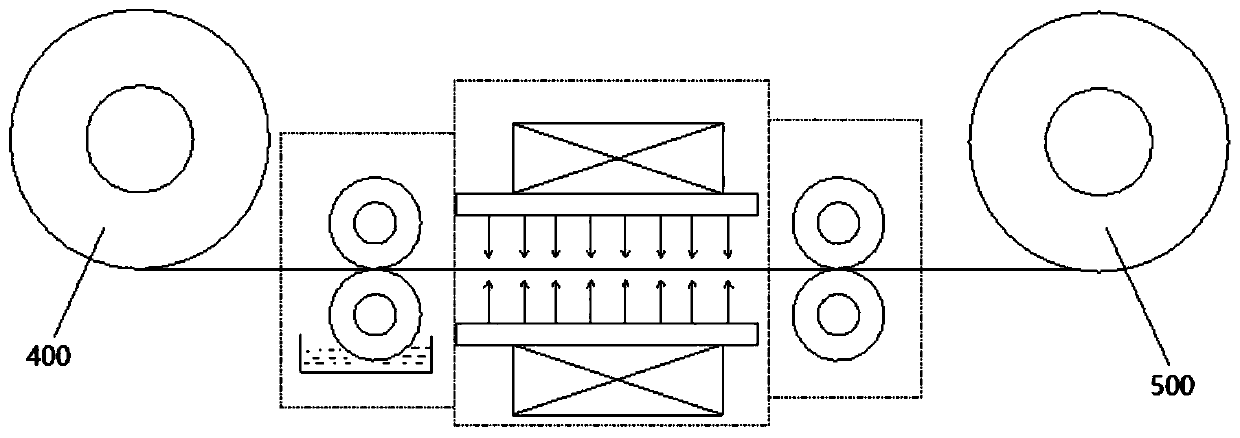

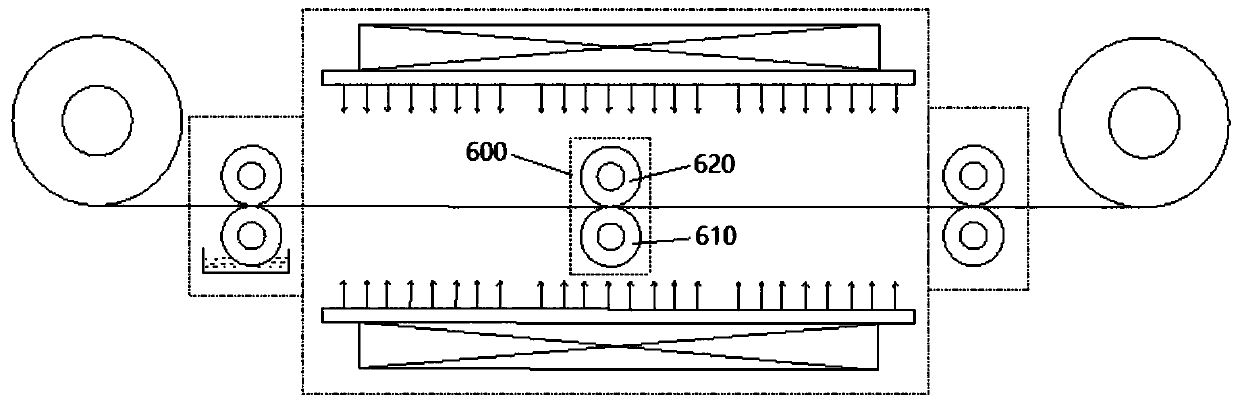

Processing device of nonwoven fabric

ActiveCN110142179AImprove stretch elasticityDifferent StretchabilityPretreated surfacesCoatingsCooking & bakingEngineering

The invention provides a processing device of nonwoven fafbric. The technical problem about how to prepare the high-elasticity nonwoven fabric on the premise that elastic glue solution raw materials do not need to be added is solved. The processing device structurally comprises a gluing mechanism, a shaping mechanism and an air pressure baking mechanism. The gluing mechanism comprises a gluing roller and a glue pressing roller. The gluing roller is provided with a first drive device. A glue solution tank is arranged below the gluing roller. The minimum distance between the roller wall of the gluing roller and the tank bottom of the glue solution tank is smaller than the tank depth of the glue solution tank. The shaping mechanism comprises a driving roller and a driven roller, wherein roller shafts of the driving roller and the driven roller are parallel. The driving roller is parallel to the gluing roller. The driving roller is provided with a second drive device. Relative to a plane determined by roller shaft lines of the gluing roller and the driving roller, air outlets of the air pressure baking mechanism are located in the upper end face and the lower end face of the plane separately. The air pressure baking mechanism is used for outputting hot air at constant temperature and constant pressure through the air outlets. The speed of drafting the nonwoven fabric through the shaping mechanism is higher than the drafting speed of the gluing mechanism. The production cost of the high-elasticity nonwoven fabric can be reduced.

Owner:浙江广鸿新材料有限公司

Manufacture method of herba dendrobii moon cakes

InactiveCN106172668APromote peristalsisPromote digestionDough treatmentBakery productsSmall intestineDigestion

The present invention belongs to the technical filed of food processing and particularly relates to a manufacture method of herba dendrobii moon cakes. The manufacture method is characterized by comprising the following steps: (1) moon cake bases are manufactured; and (2) the moon cakes are baked. Herba dendrobii powder is added into the produced herba dendrobii moon cakes, accelerates the pushing function of small intestines and the emptying function of stomach, promotes the peristalsis and digestion of the stomach, can greatly reduce the greasy taste of the moon cakes, enables the moon cakes to have health-care functions of strengthening stomach and spleen, and solves the problem that the greasiness of the moon cakes is easy to aggravate the burdens of the intestines and stomach. In the manufacture processes of the moon cakes, Manuka honey and compound starch films are also added, which can kill bacteria of the moon cake fillings, extends the shelf life of the moon cakes, and thus solves the problem that the moon cakes are easy to grow molds and denature.

Owner:GUANGXI RONGXIAN COUNTY TIANSHUN DENDROBIUM CO LTD

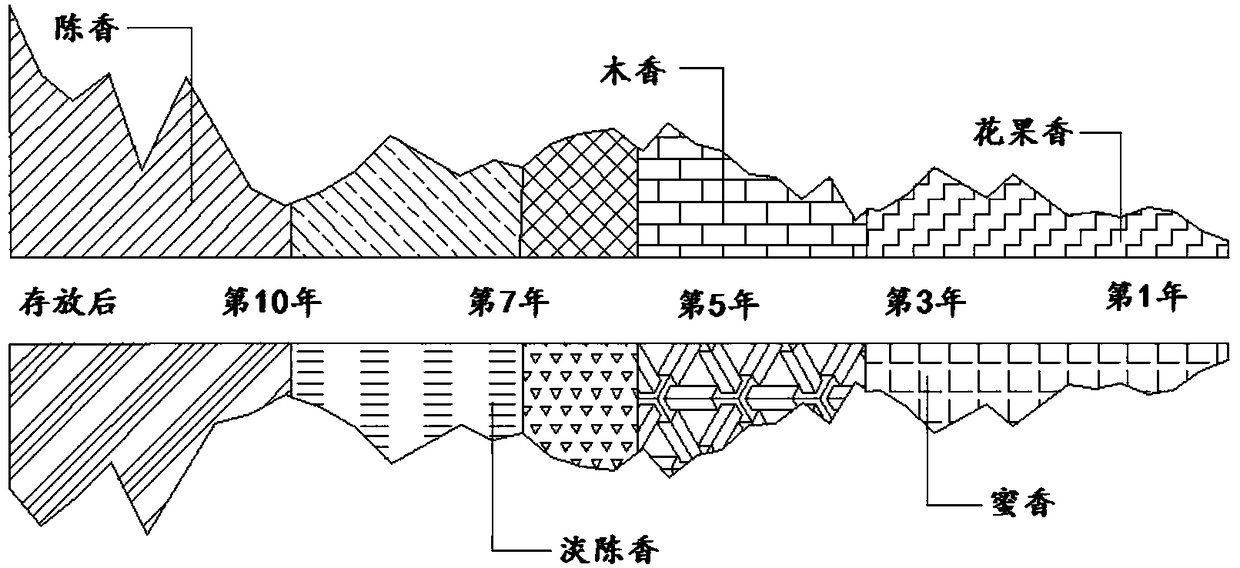

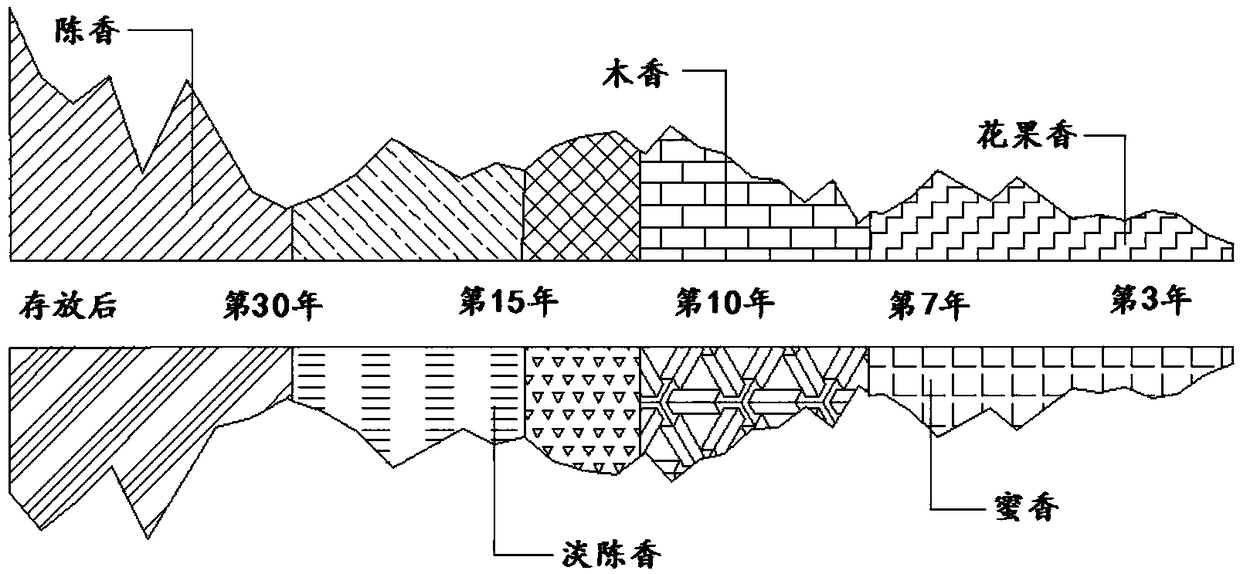

Tea clustering technology of Pu'er tea

PendingCN108077483AStable storageImprove qualityPre-extraction tea treatmentRefrigerationPrepared Material

The invention discloses a tea clustering technology of Pu'er tea. The tea clustering technology comprises the following steps of (a) selecting large-leaf variety sunning semi-finished tea as raw materials; (b) removing impurities to obtain prepared materials; (c), placing the prepared materials at a steam opening, and performing quick steaming to obtain soft prepared materials; (d) placing squarebamboo baskets in an earth isolated manner, paving bamboo shoot shells in the bamboo baskets until the periphery of the bamboo baskets is completely paved with the bamboo shoot shells, then performingstuffing in the bamboo baskets to obtain the prepared materials, and performing uniform and slight pressing; (e) repeating the step (c), stuffing the prepared materials in the bamboo baskets, and performing isolating with super-large Shanmao leaves; (f) repeating the step (e) until about 80-90% of the bamboo baskets are complete; and (g) performing refrigeration and fragrance enhancement for oneweek, then sealing the bamboo shoot shells on the surfaces, enabling the bamboo baskets to be naturally laid out in an ventilated, shady, cool and flavorless warehouse for 6 months to 3 years, and from the day of the third month, detecting humidity changes each day, and controlling the humidity to be 60-80 degrees. According to the tea clustering technology of Pu'er tea disclosed by the invention,the green taste can be removed, the quality can be improved, and the storage is stable.

Owner:卢志明

Method for building ultrathin light-load heat preservation type solar greenhouse back slope

InactiveCN102505808ALight weightReduce dead loadRoof improvementClimate change adaptationEngineeringPolycarbonate

The invention discloses a method for building an ultrathin light-load heat preservation type solar greenhouse back slope. The method comprises the following steps of: 1, building a load layer, namely connecting 4 to 6 bar-shaped steel plates and a greenhouse back slope framework along a horizontal direction to form a back slope support, and covering and fixing a layer of polycarbonate (PC) board on the back slope support; 2, building a heat preservation layer, namely sequentially paving a first asphalt felt layer, a first plastic thin film layer, a straw mattress layer, a second plastic thin film layer and a second asphalt felt layer on the upper surface of the PC board from bottom to top; and 3, building a waterproof layer, namely sequentially paving a concrete layer, a phenylethylene-butadiene-phenylethylene rubber modified asphalt layer and an aluminum foil layer on the upper surface of the second asphalt felt layer from bottom to top. The method has the advantages that: 1, the total thickness of the ultrathin light-load heat preservation type solar greenhouse back slope is 140 to 180 millimeters, and is 1 / 3 of the thickness of the conventional greenhouse back slope; 2, the unit area ratio is small, so that the constant load is reduced; 3, the cross-flow heat dissipation is reduced, and heat energy cannot be conducted outwards; 4, longitudinal and transverse torsion, vibration and deformation can be resisted; and 5, the service life is prolonged.

Owner:濮阳市林业科学院

Processing method of fructus aurantii decoction pieces

InactiveCN108498609AQuality assuranceNot easy to mold and deterioratePlant ingredientsSide effectComputer science

The invention discloses a processing method of fructus aurantii decoction pieces. The processing method mainly comprises the following steps: taking fresh fructus aurantii, performing thorough cleaning, performing moistening, performing dicing, then sequentially performing soaking with vinegar, performing covering with fresh ginger juice, performing steaming with wine, performing stir-frying and performing microwave drying to obtain the fructus aurantii decoction pieces. The processing method of the fructus aurantii decoction pieces is simple to operate, and easy to control. Through multiple technologies of soaking with vinegar, moistening with fresh ginger juice, steaming with wine, stir-frying and the like, toxic components of fructus aurantii are thoroughly removed, the quality of the fructus aurantii is guaranteed, the using requirements of medicine users are met, and besides, the condition that effective components after processing run off can be avoided; and the fructus aurantiiis not liable to mildew and deteriorate. The processed fructus aurantii is mild in drug property, small in side effects, suitable for being absorbed and utilized by human bodies, and has high medicalvalue.

Owner:ANHUI YIYUAN PHARMA CO LTD

Automatic brown rice grinding device

InactiveCN109012874ANot easy to mold and deteriorateExtended storage timeCocoaGrain treatmentsElectric machineryEngineering

The invention discloses an automatic brown rice grinding device. The automatic brown rice grinding device comprises a device body, wherein one side of the device body is provided with a feeding inlet,an observation window is arranged on the outer surface of the device body, a storage bin is arranged at the bottom of the device body, and supporting columns are arranged at the bottom of the storagebin. According to the automatic brown rice grinding device, when grinding is carried out, a user can observe the grinding condition in the device body through the observation window, and meanwhile amotor can drive a rotating disc to rotate through a rotating shaft, so that grinding balls arranged at the bottom of the rotating disc and a grinding block jointly grind brown rice in the device body,and a discharging pipe arranged at the bottom of the device body can be used for further screening the ground brown rice. The ground brown rice particles with the precision meeting the requirement can enter a collecting cabinet through the discharging pipe, the larger ground brown rice particles continue to be ground, and the well-ground brown rice particles can enter the collecting cabinet through the discharging pipe after meeting the requirement to be automatically collected, so that the working efficiency of the device is improved.

Owner:徐莉莉

Preparation method of straw microbial silage stored in plastic silo

InactiveCN110463820AIncrease profitImprove the environmentFood processingAnimal feeding stuffBiotechnologyFodder

The invention provides a preparation method of straw microbial silage stored in a plastic silo. The method takes feed crops such as straw, pasture and vines as raw materials, and comprises the steps of construction of a temporary microbial silage silo, resurrection of strains, preparation of a diluent, and preparation of the straw microbial silage stored in the plastic silo. The prepared microbialsilage is wide in raw material sources, low in cost, good in palatability, simple to operate, convenient to store and take, suitable for long-term storage and very suitable for popularization and application of moderate-scale farmers.

Owner:蔺军

Method for building ultrathin light-load heat preservation type solar greenhouse back slope

InactiveCN102505808BLight weightReduce dead loadRoof improvementClimate change adaptationEngineeringPolycarbonate

The invention discloses a method for building an ultrathin light-load heat preservation type solar greenhouse back slope. The method comprises the following steps of: 1, building a load layer, namely connecting 4 to 6 bar-shaped steel plates and a greenhouse back slope framework along a horizontal direction to form a back slope support, and covering and fixing a layer of polycarbonate (PC) board on the back slope support; 2, building a heat preservation layer, namely sequentially paving a first asphalt felt layer, a first plastic thin film layer, a straw mattress layer, a second plastic thin film layer and a second asphalt felt layer on the upper surface of the PC board from bottom to top; and 3, building a waterproof layer, namely sequentially paving a concrete layer, a phenylethylene-butadiene-phenylethylene rubber modified asphalt layer and an aluminum foil layer on the upper surface of the second asphalt felt layer from bottom to top. The method has the advantages that: 1, the total thickness of the ultrathin light-load heat preservation type solar greenhouse back slope is 140 to 180 millimeters, and is 1 / 3 of the thickness of the conventional greenhouse back slope; 2, the unit area ratio is small, so that the constant load is reduced; 3, the cross-flow heat dissipation is reduced, and heat energy cannot be conducted outwards; 4, longitudinal and transverse torsion, vibration and deformation can be resisted; and 5, the service life is prolonged.

Owner:濮阳市林业科学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com