Natural fiber-reinforced thermoplastic composite material prepreg tape, and preparation method and application thereof

A technology for reinforcing thermoplastic and natural fibers, which is applied in chemical instruments and methods, textiles and papermaking, and synthetic resin layered products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Pretreating polypropylene to obtain strip fibers with a fineness of 35 deniers;

[0054] (2) Get the sliver of hemp fiber and draw the above-mentioned polypropylene sliver to prepare a roving of 10 public counts, wherein the polypropylene content is 48.5%, and the hemp fiber content is 51.5%;

[0055] (3) Sizing the prepared blended yarn once;

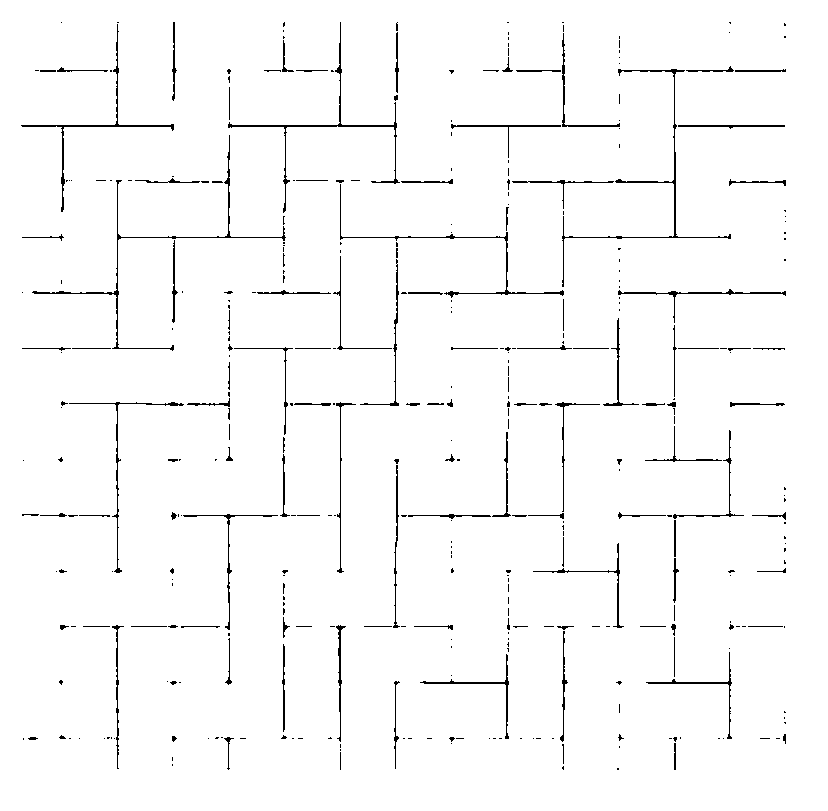

[0056] (4) Process the above-mentioned yarns into plain weave fabrics by loom, as shown in Figure 1(b);

[0057] (5) Desizing the prepared fabric once to obtain a natural fiber reinforced thermoplastic composite material prepreg tape.

[0058] (6) Take hemp fiber reinforced thermoplastic composite prepreg tape, the thickness of each layer of prepreg tape is 0.5mm, and the weight is 360g / m 2 ;

[0059] 20 layers of fabric laying, of which 1, 3, 5, 7, 9, 11, 13, 15, 17, and 19 layers are all in the direction of 0 degrees, 2, 4, 6, 8, 10, 12, 14, The 16th, 18th, and 20th layers are laid in a direction of 90 degrees, and the t...

Embodiment 2

[0064] (1) Pretreating polypropylene to obtain strip fibers with a fineness of 35 deniers;

[0065] (2) get jute fiber sliver and above-mentioned polypropylene sliver and carry out draw frame, prepare to form the roving of 15 public counts, wherein polypropylene content is 45%, and jute fiber content is 55%;

[0066] (3) Process the above-mentioned yarns into a twill fabric by using a loom, as shown in Figure 1(a), to obtain a natural fiber-reinforced thermoplastic composite material prepreg tape;

[0067] (4) Take jute fiber reinforced thermoplastic composite material prepreg tape, the thickness of each layer of prepreg tape is 0.4mm, and the weight is 300g / m 2 ;

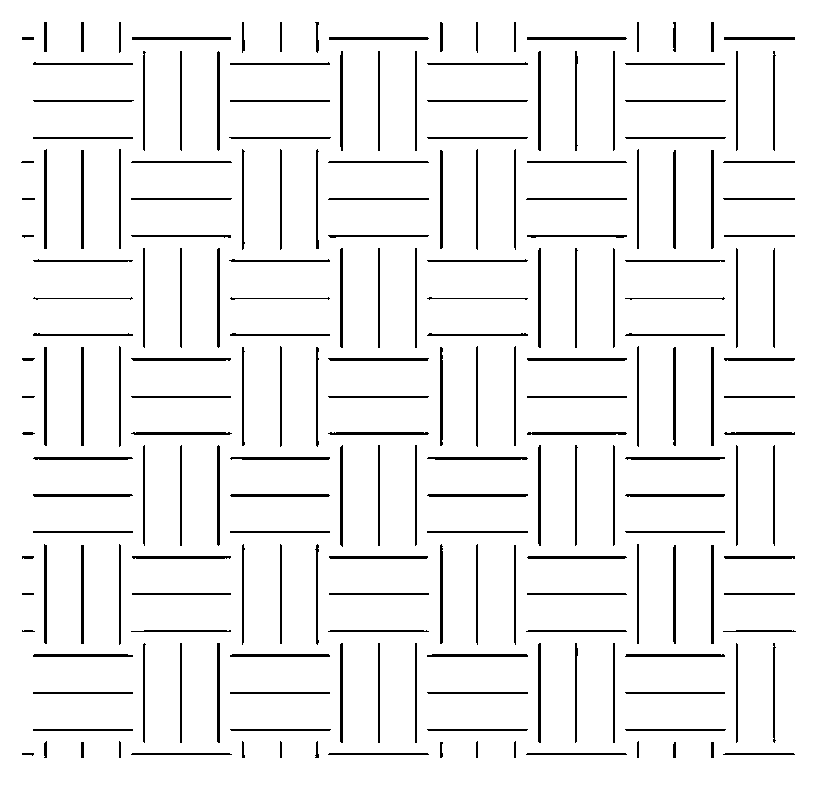

[0068] 26 layers are laid up, of which layers 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, 23, and 25 are all in the direction of 0 degrees, 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, and 26 layers are laid in a direction of 90 degrees; the thickness of the layer is 8cm, such as figure 2 shown;

[0069] (5) Heat the...

Embodiment 3

[0073] (1) Pretreat polylactic acid to obtain strip fibers with a fineness of 40 denier;

[0074] (2) Get the sliver of ramie fiber and carry out draw frame with above-mentioned polypropylene sliver, prepare the roving of 36 public counts, wherein polylactic acid content is 55%, and ramie fiber content is 45%;

[0075] (3) Sizing the prepared blended yarn once;

[0076] (4) Process the above yarns into twill fabrics by loom, as shown in Figure 1(a);

[0077] (5) Desizing the prepared fabric once to obtain a natural fiber reinforced thermoplastic composite material prepreg tape.

[0078] (6) Take natural fiber reinforced thermoplastic composite material prepreg tape; the thickness of each layer of prepreg tape is 0.18mm, and the weight is 160g / m 2 ;

[0079] 35 layers of lay-up, of which 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, 23, 25, 27, 29, 31, 33, and 35 layers are all in the direction of 0 degrees . Such as figure 2 shown;

[0080] (7) Heat the laminated prepreg tape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com