Processing method of prepared rehmannia root

A technology of rehmannia glutinosa and rice wine, which is applied to medical preparations containing active ingredients, medical formulas, plant raw materials, etc. It can solve the problems of long stewing time of rehmannia glutinosa rice wine, easy breeding of a large number of bacteria, and limited space for drying, so that it is not easy to breed Bacteria, not easy to mold and deteriorate, and the effect of short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

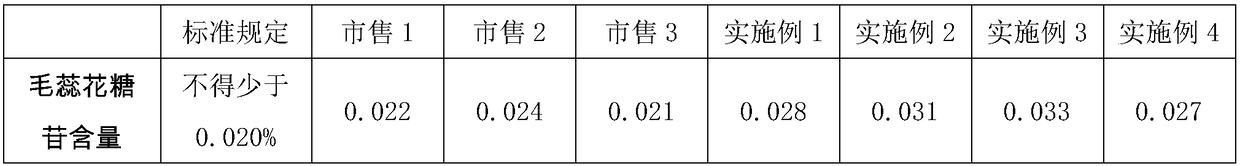

Examples

Embodiment 1

[0020] The preparation of embodiment 1 Rehmannia glutinosa of the present invention

[0021] In the processing process of rehmannia glutinosa, the present invention adopts rehmannia rehmannia cut into thick slices (4mm), dried at 55°C±5°C for 3 hours, puts it into a rotary steamer while it is hot, adds rice wine (100kg rehmannia glutinosa, uses 30-50kg rice wine ) for 1 hour; the purpose of this process link is to reduce the water content of rehmannia glutinosa, which is beneficial to the infiltration of rice wine. According to the slice thickness to achieve a certain degree of infiltration.

[0022] Steam for 3 hours (the steaming process rotates back and forth at a speed of 5-10 rpm every 10-20 minutes to ensure uniform cooking), turn off the steam, keep warm for 1 hour, and take it out; the process link reaches the goal of steaming According to the thickness of the slices, choose the steaming time, 2mm slices can be steamed in 2 hours; 4mm slices can be steamed in 3 hours;...

Embodiment 2

[0025] The preparation of embodiment 2 Rehmannia glutinosa of the present invention

[0026] In the processing process of rehmannia glutinosa, the present invention adopts rehmannia rehmannia cut into thick slices (4mm), dried at 65°C±5°C for 2 hours, puts it into a rotary steamer while it is hot, and adds rice wine (100kg rehmannia glutinosa, 30-50kg rice wine ) for 1 hour, steam for 3 hours (the steaming process rotates back and forth at a speed of 5-10 rpm every 10-20 minutes to ensure uniform cooking), turn off the steam, keep warm for 1 hour, take it out, use Through-flow oven (with dust removal hood and reflux device), drying at 55°C±5°C, drying thickness 5cm, continuous drying for 50 hours, the reflux device can recycle hot steam and reduce energy consumption.

Embodiment 3

[0027] The preparation of embodiment 3 Rehmannia glutinosa of the present invention

[0028] In the processing process of rehmannia glutinosa, the present invention adopts rehmannia rehmannia cut into thick slices (2mm), dried at 55°C±5°C for 3 hours, puts it into a rotary steamer while it is hot, and adds rice wine (100kg rehmannia glutinosa, 30-50kg rice wine ) for 0.5 hours, steam for 2 hours (the steaming process rotates back and forth at a speed of 5-10 rpm every 10-20 minutes to ensure uniform cooking), turn off the steam, keep warm for 0.5 hours, take it out, use Through-flow oven (with dust removal hood and reflux device), drying at 55°C±5°C, drying thickness 5cm, continuous drying for 40 hours, reflux device can recycle hot steam and reduce energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com