Rotary reciprocating type tea screening and processing device

A processing device and reciprocating technology, applied in the directions of tea drying, sieving, drying gas arrangement, etc., can solve the problems of many impurities and different thicknesses, and achieve the effect of improving screening accuracy, low manufacturing cost and improving screening accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

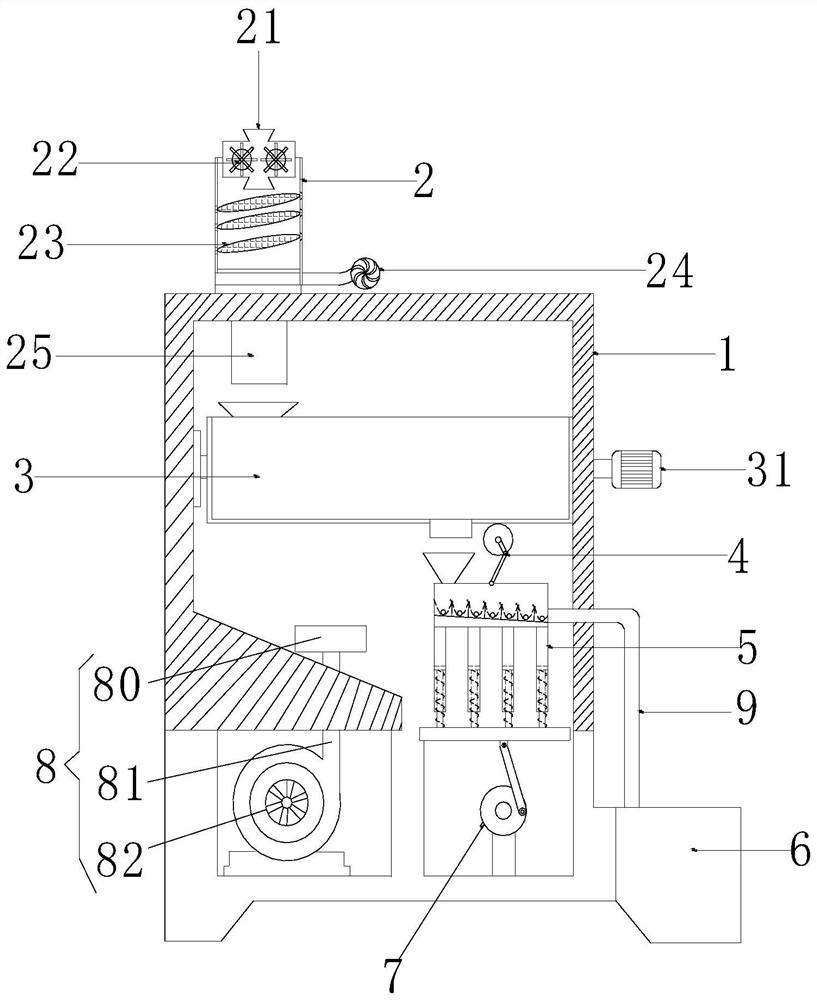

[0036] See figure 1 , The present embodiment provides a rotating and reciprocating tea screening and processing device;

[0037] The box body 1 is the main body of the whole device, and ancillary equipment and a movable drying mechanism are arranged inside the box body 1 .

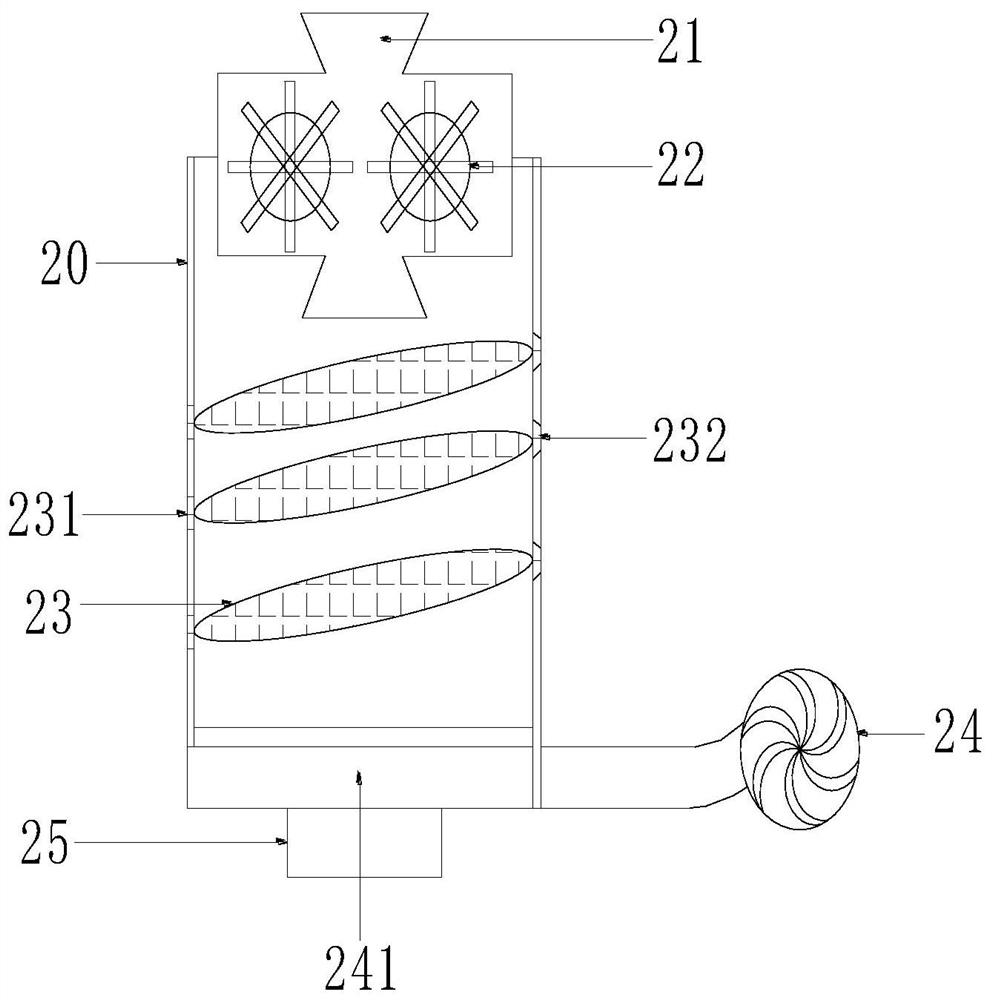

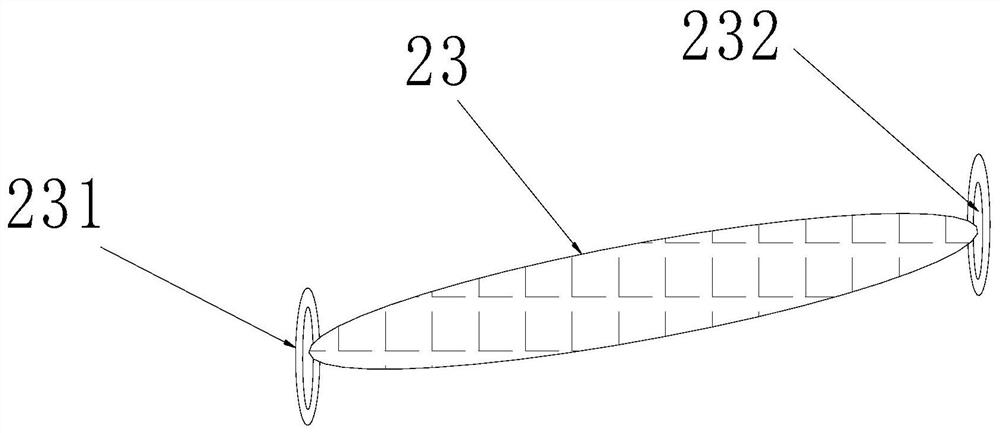

[0038] See figure 2 , image 3 , the screening box 2 is fixed on the top of the box body 1, and the screening box body 20 of the screening box 2 communicates with the inside of the box body 1; the inside of the screening box 2 is inclined to set at least three layers of screens 23; A gear 231 is provided, and the gear 231 is connected by a bearing 232; the bearings 232 are respectively fixed on the two ends of the screen 23; the inclination angle of the screen 23 is 30 degrees, and in the screen 23, the aperture of the upper layer is larger than that of the lower layer caliber.

[0039] See figure 1 , Figure 4 , the rotation of the stir-fry tube 3 is arranged inside the box body 1; the stir-fry tub...

Embodiment 2

[0053] refer to figure 1 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment adds a cold air drying device 8 on the basis of Embodiment 1; the cold air drying device 8 is fixed in the inner cavity of the box body 1 and is located Device 5 side; Described cold air drying device 8 comprises fan 81, air delivery pipe 82, spray pipe 80; The spray pipe 80 below the frying tube 3 is connected to each other.

[0054] During specific work, the blower fan 81 transports the air flow to the nozzle 80 through the air delivery pipe 82, and blows air to the upper stirrer 3 through the nozzle 80; it can fully bake the tea leaves in the stirrer 3 that is continuously rolling and stirring. Drying achieves the purpose of uniform drying of tea leaves, greatly improves the drying efficiency of tea leaves, and also improves the drying effect of tea leaves and the processing quality of tea leaves.

Embodiment 3

[0056] refer to figure 1 , Figure 6 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment adds a shaking device 7 on the basis of Embodiment 1, and the shaking device 7 is fixed on the bottom of the drying box 50; the shaking device 7 includes shaking Motor 72, disc 70, connecting rod 71; Rocking motor 72 is fixed on casing 1 bottom; The output shaft end of shaking motor 72 is fixed with disc 70, and the outer front end face of disc 70 is hinged with connecting rod 71, and connecting rod 71 other ends are hinged with the drying device 5 bottoms. During specific work, the shaking motor 72 drives the disc 70 to rotate, and the connecting rod 71 is driven by the 70 of the disc to realize rocking back and forth to the drying box 50 on the top. The shaking device 7 is in the waiting state when the reciprocating mechanism 4 and the internal electromagnetic device of the drying device 5 can operate normally, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com