Movable distributive continuous exploitation method for deep sea mineral resources

A technology for mineral resources and mining methods, applied in the fields of mining minerals, earth-moving drilling, special mining, etc., can solve problems such as the destruction of marine life in the marine environment, difficulty in improving productivity, and reducing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

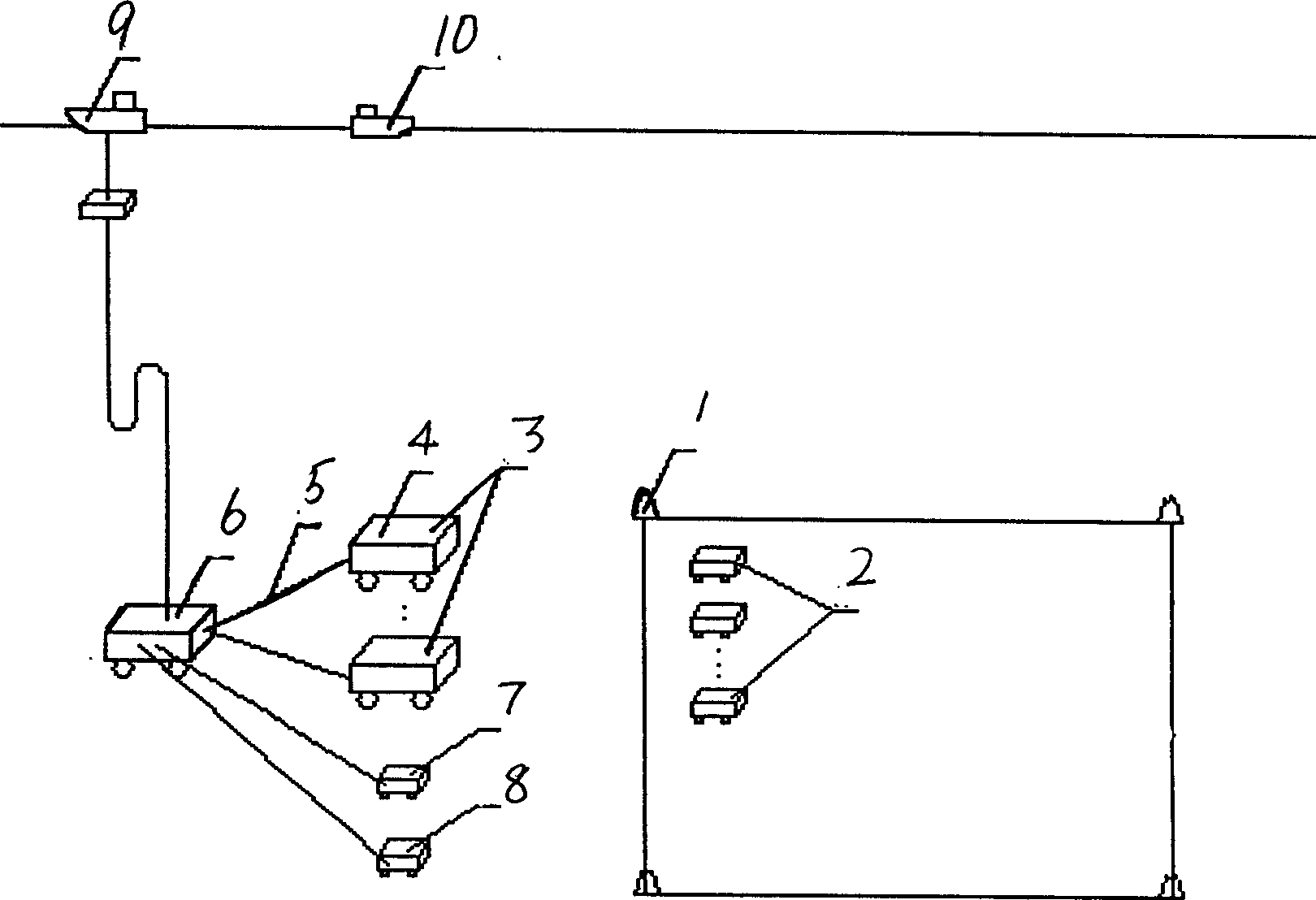

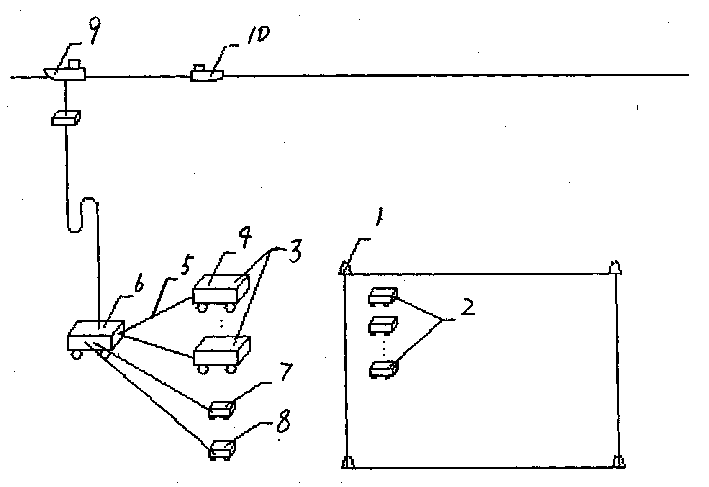

[0009] Referring to the accompanying drawings, the mining mode of the patent of the present invention is mainly composed of the underwater positioning base point 1 of the marine mining area, the mobile distributed mining vehicle 2, the mobile mine bin 3 matched according to the mining volume, and a belt that can effectively suppress the dilution rate. The primary separation and primary crushing device that matches the particle size of the lifting ore 4, the transmission device that is transported to the lifting ore device 5, the mobile lifting ore device with power and pipelines 6, the mobile underwater total power distribution station 7, the mobile The main control station 8 of the underwater mining task, the mining ship 9 on the water surface, the transport ship 10 and other parts are composed. After the mining path, the sensor on the mining vehicle 2 compares the mining area positioning base point 1 to determine its position in the mining area, and mines according to the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com