A Controlled Blasting Method for Reducing Loss and Depletion

A technology for controlling blasting and depletion, applied in blasting and other directions, can solve problems affecting ore mining, beneficiation costs, and reduce mine economic benefits, and achieve the effects of controlling loss and dilution rate, good economic benefits, and efficient and precise separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better describe the present invention, a controlled blasting method for reducing loss and depletion of the present invention will be further described in detail below in conjunction with the accompanying drawings.

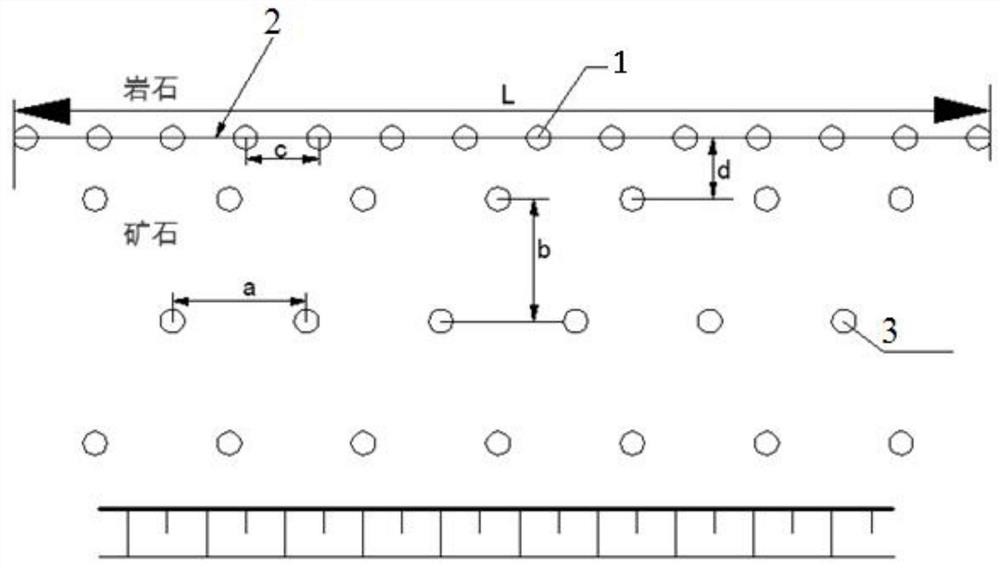

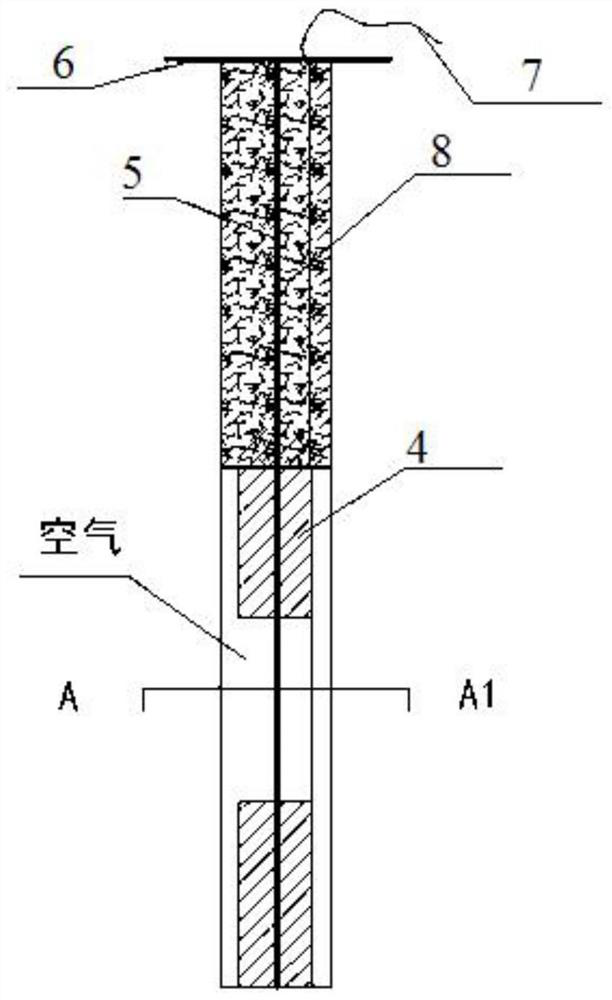

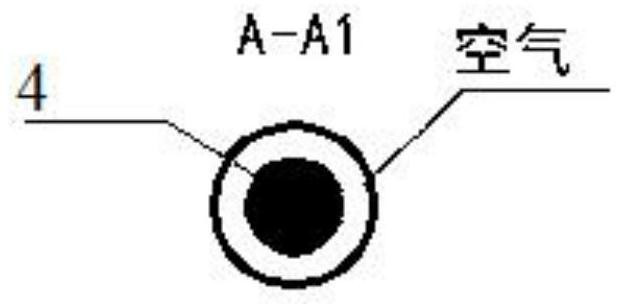

[0019] Depend on figure 1 A control blasting method for reducing loss and depletion of the present invention is shown in the plan view of the control blasting technology. It can be seen that a controlled blasting method for reducing loss and depletion of the present invention is carried out on the open-air steps of pre-blasting according to the designed hole network parameters— The hole spacing a and the row spacing b are used to arrange the main charge blasting hole 3, and the ore-rock differentiation blasting hole 1 is arranged on the ore-rock boundary line 2, and the ore-rock differentiation blasting hole 1 hole spacing c is the main charge 0.6~0.9 times of the hole distance a of the blasting hole 3, and the rejection d between the blasting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com