Disperse die, disperse die composition, ink for ink-jet printing, and staining method and stained material using the die, composition or ink

A technology of disperse dyes and compositions, applied in the fields of inkjet printing and dyeing inks, dyeing methods and dyed objects, can solve the problems of poor sublimation fastness, insufficient light fastness, difficult dyeing depth performance, etc., and achieve excellent dyeing properties, sublimation Excellent firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0130]The method for preparing the ink for inkjet recording of the present invention is not particularly limited, but it is preferably prepared by the following method. That is, first, (a) each dye used in the above-mentioned orange disperse dye, the above-mentioned first to fourth disperse dye compositions, and the first and second disperse dye compositions for mixing, a dispersant, water, and if necessary And the added water solvent, organic solvent or the above-mentioned additives are mixed and stirred to prepare a pre-dispersion liquid. Next, (b) disperse the above-mentioned pre-dispersion liquid using a wet media mill such as a sand mill to obtain a dispersion liquid of each of the above-mentioned dyes. (c) When preparing the ink of only the above-mentioned orange disperse dye, water, a water-soluble organic solvent, and the above-mentioned additives added as needed can be added to the above-mentioned dispersion liquid to adjust the concentration, and then filtered throug...

Embodiment 1

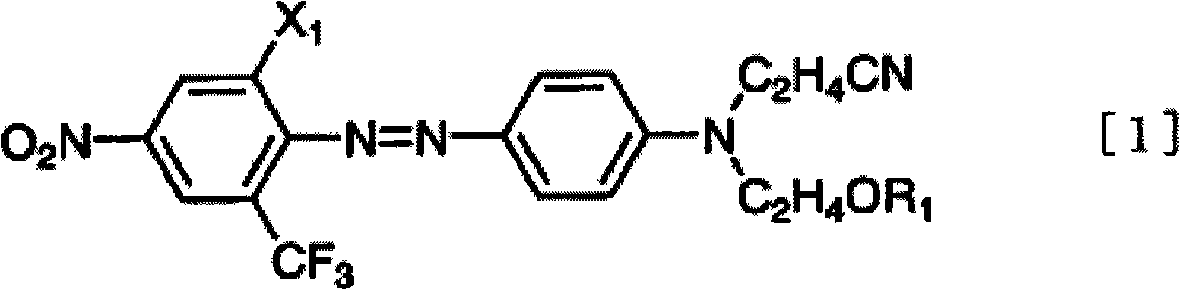

[0138] (Example 1) [synthesis of orange disperse dye [1-1]]

[0139] A mixture of N-cyanoethyl-N-hydroxyethylaniline (18.7 parts) and β-picoline (10.9 parts) was warmed to 50°C. Then, benzoyl chloride (16.8 parts) was added dropwise to the above mixture within 3 hours at 60-70° C., and then kept at the same temperature for 1 hour to obtain N-cyanoethyl-N-benzoyloxy Ethylaniline. Sulfamic acid (2 parts) was added to the mixture, and 120 parts of acetic acid was added to dissolve it, and then ice was added to adjust the mixture to 5-10°C to obtain a coupling agent solution.

[0140] Slowly add 2-cyano-3-chloro-5- Nitro-1-trifluoromethylbenzene (24 parts). By keeping the above mixture at 5-10°C for 4 hours, a diazo compound was obtained.

[0141] Ice was properly added to the above coupling agent solution to keep the temperature at 5-10°C, and at the same time, the above diazo compound solution was added dropwise within 3 hours to carry out the coupling reaction.

[0142] Th...

Embodiment 2

[0144] (Example 2) [synthesis of orange disperse dye [1-2]]

[0145] Using 2-cyano-3-bromo-5-nitro-1-trifluoromethylbenzene (28.5 parts) instead of 2-cyano-3-chloro-5-nitro-1-trifluoromethylbenzene, And use N-cyanoethyl-N-cyanoethoxyethylaniline to replace N-cyanoethyl-N-benzoyloxyethylaniline, except that, according to the same as in Example 1 The dyestuff represented by the following formula [1-2] is obtained by the method. In addition, N-cyanoethyl-N-cyanoethoxyethylaniline was produced as follows. The mixture of N-cyanoethyl-N-hydroxyethylaniline (18.7 parts) and acrylonitrile (14.9 parts) was heated to 80-90°C and kept at the same temperature for 2 hours to obtain N-cyanoethyl -N-cyanoethoxyethylaniline.

[0146] The obtained following formula [1-2] represents the maximum absorption wavelength (λ max ) is 429nm.

[0147]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com