Highly weather-resistance co-extruding material PVC pipe and production method thereof

A technology for PVC pipes and production methods, which is applied in the field of high-weather-resistant co-extruded PVC pipes and production, can solve the problems of high price, damage, thermal expansion and contraction rate of PVC deformation, etc., so as to improve recycling rate and impact resistance , Improve the effect of pipe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A high weather resistance co-extruded PVC pipe made of the following raw materials in weight percentage: polycarbonate: 20%, PMMA: 10%, insulating ceramic particles with a diameter of 0.05 mm: 8%, and a length of 3 glass Fiber: 5%, Titanium Dioxide, 5%, Talc: 1%, Magnesium Oxide: 3%, CPE: -3%, Calcium Carbonate: 3%, ACM: 1%, Sodium Stearate: 2%, Copper Oxalate: 2%, dimethyl trimethylsilylmethyl phosphate: 2%, antistatic agent: 0.5%, coloring pigment: 1%, lubricant: 0.1%, dispersant: 0.5%, antioxidant: 0.3%, ultraviolet absorber : 0.7%, acid-resistant ultramarine: 0.3%, fluorescent whitening agent: 0.2%, PVC lubricant: 0.3%, smoke suppressant: 0.3%, and the balance is PVC.

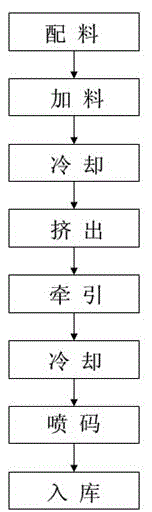

[0023] A method for producing a high weather-resistant co-extrusion material PVC pipe, comprising the steps of:

[0024] The first step: ingredients, the raw materials polycarbonate, CPE, stabilizer, ACM%, sodium stearate, copper oxalate, dimethyl trimethylsilyl phosphate, antistatic agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com