A large-scale shielded main pump dismantling device and dismantling process in a radioactive environment

A radioactive and environmental technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as impeding core pulling of rotor components, lower radial bearings cannot be disassembled normally, and achieve displacement deformation Minimize, reduce the risk of contamination by radioactive media, and improve the quality and efficiency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] A dismantling device for a large shielded main pump in a radioactive environment, including an impeller nut locking pin removal assembly, a C-shaped ring cutting assembly, a lower radial bearing disassembly, and a rotor core pulling assembly. in:

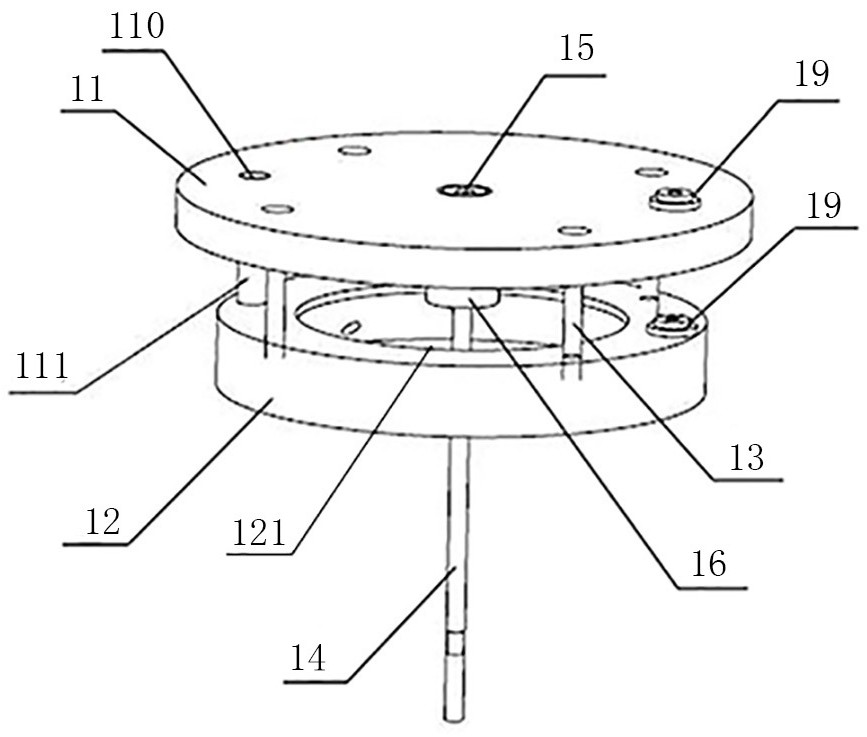

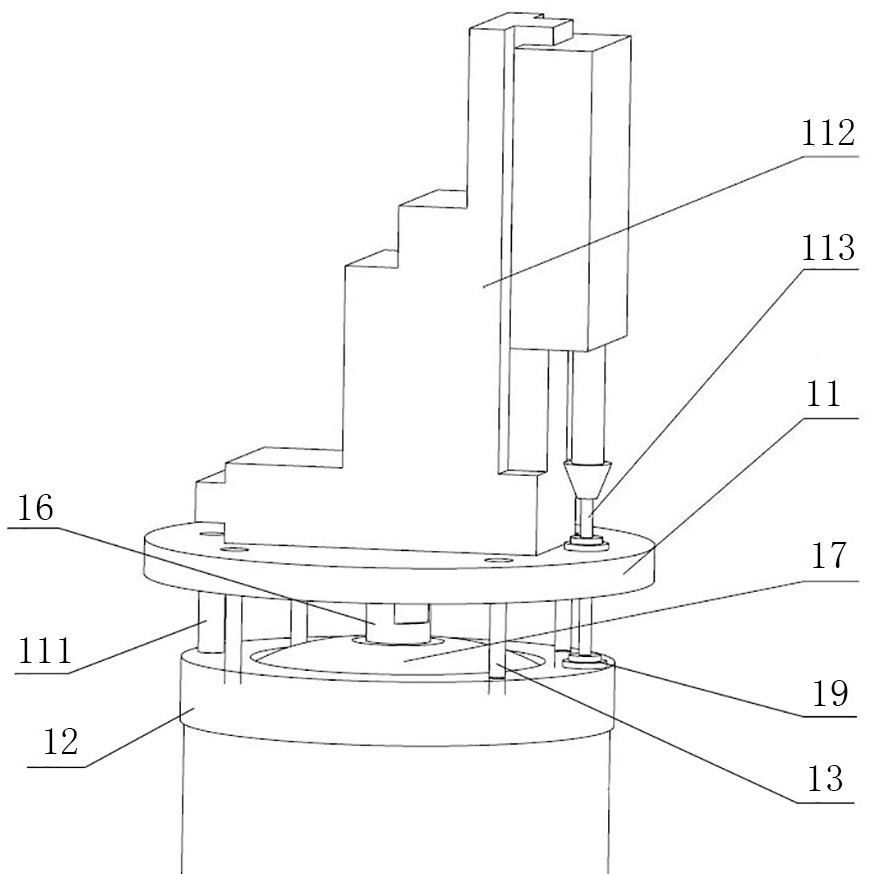

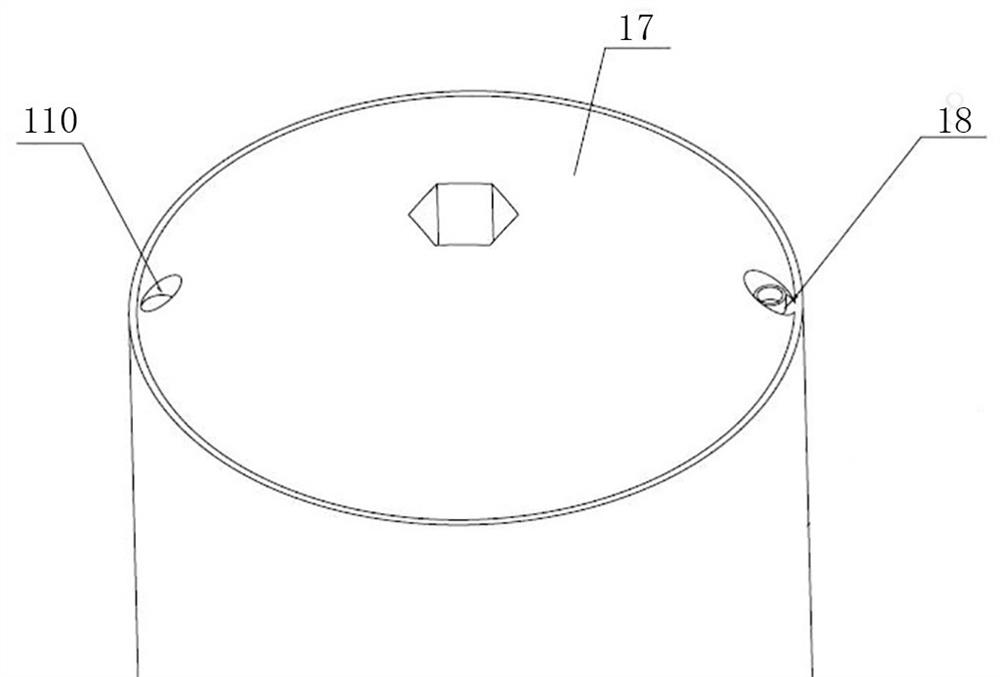

[0053] Such as Figure 1-3 As shown, the impeller nut locking pin removal assembly includes an upper plate 11, a lower plate 12, a connecting screw 13, a double-ended screw rod 14, a fixing nut 15, and an adjusting nut 16; the upper plate 11 and the lower plate 12 pass through the The connecting screw 13 is connected, and one end of the double-ended screw rod 14 is connected to the upper plate 11 through the fixing nut 15, and the other end passes through the lower plate 12 downwards, and is screwed to the impeller nut 17; the adjustment The nut 16 is arranged on the double-headed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com