Formaldehyde removal solid powder coating and preparation method thereof

A technology for solid powder and coatings, applied in powder coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of low utilization efficiency of visible light, easy deactivation of catalysts, etc., and achieve remarkable formaldehyde removal effect, simple preparation method, Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

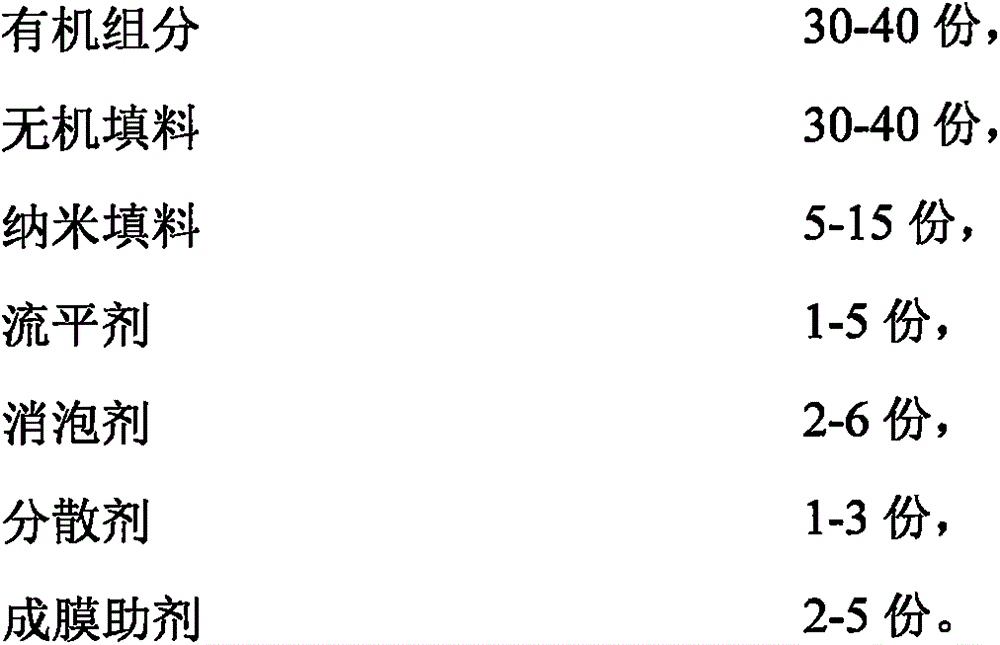

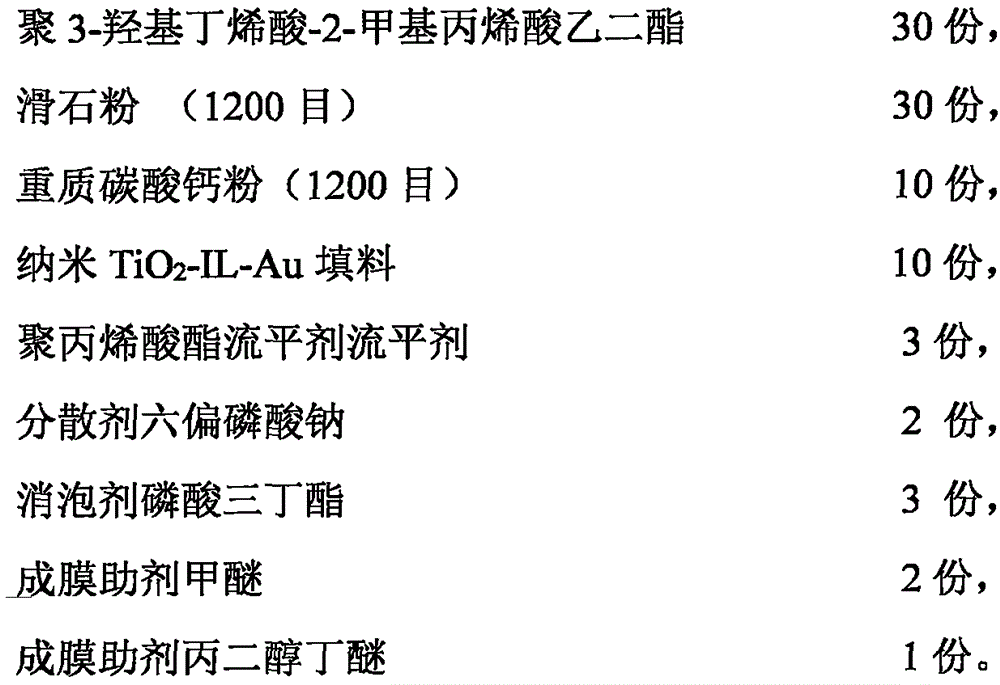

[0034] The formaldehyde-removing solid powder coating in the present embodiment is made up of the raw material of following weight portion:

[0035]

[0036] Wherein, the preferred preparation method of described nanofiller comprises the steps:

[0037] 1) React 120g of chloropropyltriethoxysilane and 34.4g of 1,2,4-1H-triazole under a nitrogen atmosphere at 110°C for 24 hours; after naturally cooling to room temperature, wash with anhydrous ether 5 times, Then put it in a vacuum drying oven and dry it at 80°C for 12 hours, and the obtained yellow viscous liquid is triazole salt;

[0038] 2) Take 60g of the triazole salt obtained in step 1) and add it to the suspension with 90g of TiO 2 Nanoparticles in chloroform, wherein the mass of chloroform is 270g, under a nitrogen atmosphere, reflux and stir at 80°C for 24h, centrifuge the obtained product, wash the separated solid with chloroform repeatedly, and place it in a vacuum drying oven at 80°C Drying for 10 h under the ho...

Embodiment 2

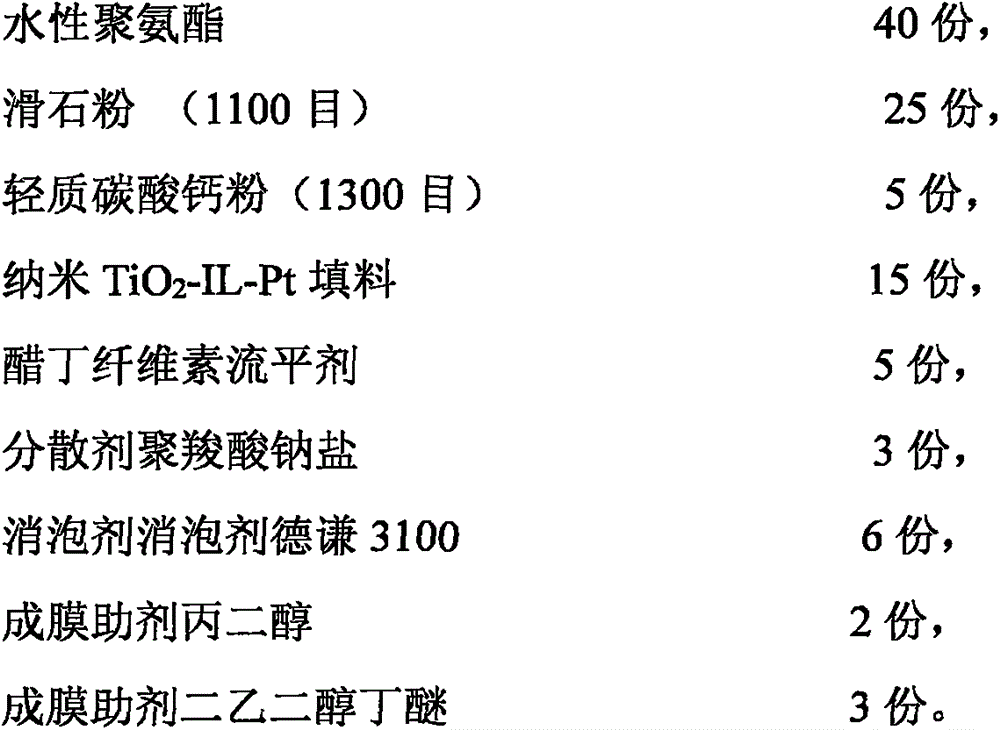

[0044] The formaldehyde-removing solid powder coating in the present embodiment is made up of the raw materials of following parts by weight

[0045]

[0046] Wherein, the preferred preparation method of described nanofiller comprises the steps:

[0047] 1) React 120g of chloropropyltriethoxysilane and 66.35g of tolyltriazole at 90°C for 36h under a nitrogen atmosphere; wash with anhydrous ether for 3 times after naturally cooling to room temperature, and then put Dry in a vacuum oven at 60°C for 24 hours, and the obtained yellow viscous liquid is triazole salt;

[0048] 2) Take 40g of the triazole salt obtained in step 1) and add it to the suspension with 120g of TiO 2 Nanoparticles in chloroform, wherein the mass of chloroform is 600g, under nitrogen atmosphere, reflux and stir at 100°C for 24h, centrifuge the obtained product, wash the separated solid with chloroform repeatedly, and place it in a vacuum drying oven at 60°C Drying for 20h under the hood to obtain IL-TiO...

Embodiment 3

[0054] Weigh various raw materials according to the ratio of mass and number stated below

[0055]

[0056] Wherein, the preferred preparation method of described nanofiller comprises the steps:

[0057] 1) React 120g of chloropropyltriethoxysilane and 66.35g of 1-methylbenzotriazole under a nitrogen atmosphere at 100°C for 30h; after naturally cooling to room temperature, wash with anhydrous ether 4 times, and then put Dry in a vacuum oven at 70°C for 20 hours, and the obtained yellow viscous liquid is triazole salt;

[0058] 2) Take 30g of the triazole salt obtained in step 1) and add it to the suspension with 60g of SiO 2 Nanoparticles in chloroform, wherein the mass of chloroform is 240g, under a nitrogen atmosphere, reflux and stir at 90°C for 24h, centrifuge the obtained product, wash the separated solid with chloroform repeatedly, and place it in a vacuum drying oven at 70°C Drying for 15h under the hood to obtain IL-SiO 2 ;

[0059] 3) Take 20g of step 2) to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com