Preparation method of nano cuprous oxide

A technology of nano-cuprous oxide and cuprous oxide, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of increasing preparation costs and difficult cleaning, and achieve abundant raw materials, low cost, and repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of nano-cuprous oxide, the method is specifically: 10mL concentration of 0.05moL / L copper nitrate aqueous solution is dripped into a beaker filled with 50mL deionized water, then adding 0.5mL concentration of 2mol / L copper nitrate NaOH aqueous solution, stirred evenly at room temperature, then added 0.032g hydrazine hydrate, stirred for 40min to obtain a reddish brown precipitate, the product was centrifuged, washed three times with deionized water and absolute ethanol, and placed in a vacuum oven at 60°C Drying for 6 hours under the hood to obtain octahedral cuprous oxide nanomaterials.

[0015] A method for preparing nano-cuprous oxide, the method specifically comprising: dissolving 0.025g of copper sulfate pentahydrate and 0.05g of polyvinylpyrrolidone in 15mL of absolute ethanol, stirring at room temperature for 2 hours to fully dissolve. Then add a mixed solution consisting of 0.072g glucose, 0.032g sodium hydroxide, and 10g water, stir for 20m...

Embodiment

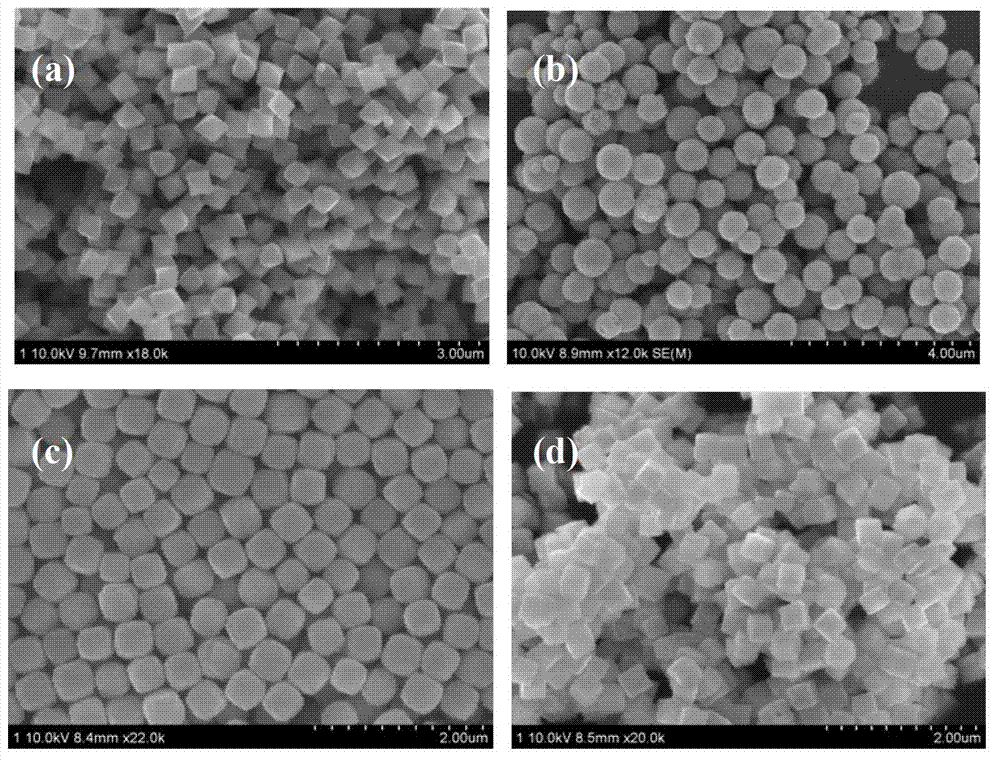

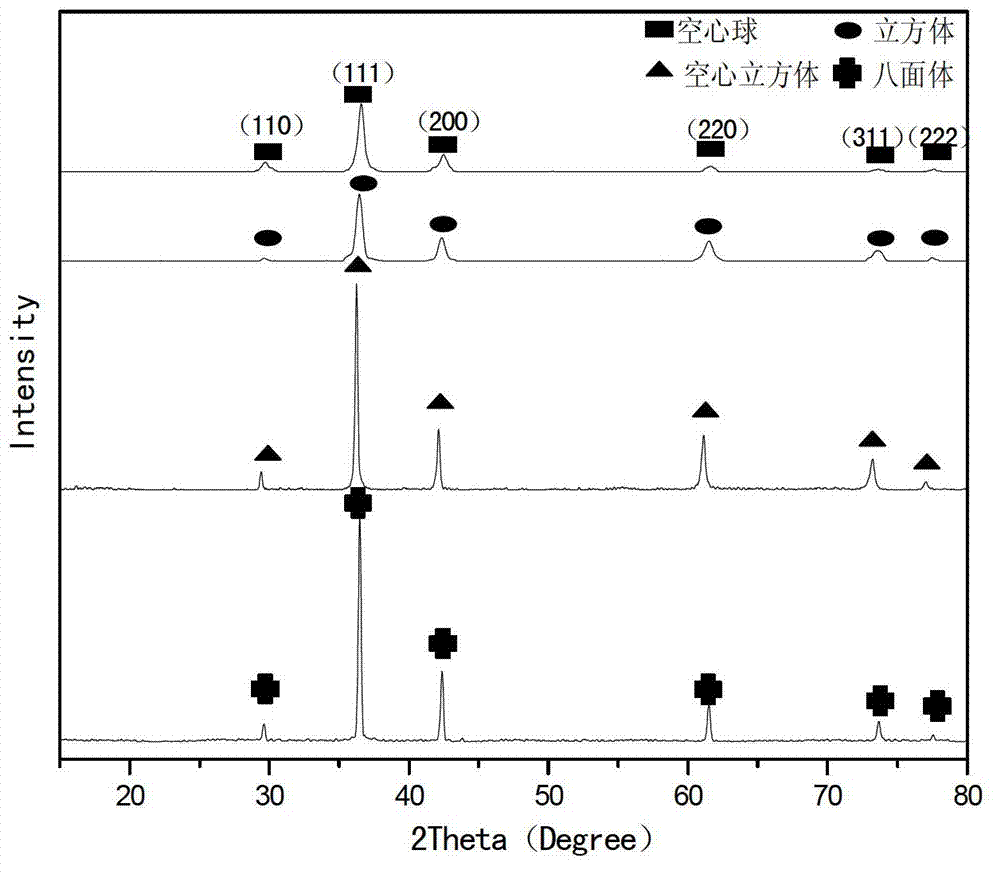

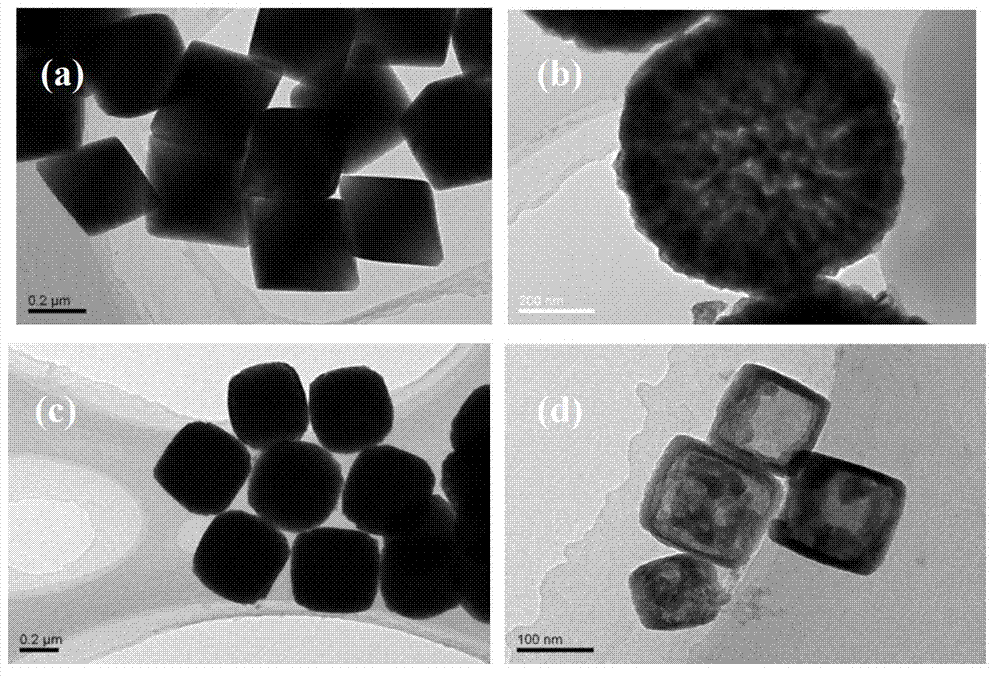

[0019] (1) Octahedral cuprous oxide nanomaterials: 10mL copper nitrate aqueous solution with a concentration of 0.05moL / L is used as a copper source, put it into a beaker filled with 50mL deionized water, and add 0.5mL NaOH aqueous solution with a concentration of 2mol / L Adjust the pH of the solution, stir evenly at room temperature, then add 0.032g hydrazine hydrate as a reducing agent, and stir for 40 minutes to obtain a reddish-brown precipitate. The product is centrifuged, washed three times with deionized water and absolute ethanol, and placed in vacuum drying Dry in an oven at 60°C for 6 hours to obtain octahedral cuprous oxide nanoparticles. figure 1 (a) is a scanning electron microscope picture of octahedral copper oxide nanomaterials. It can be seen from the figure that the obtained octahedrons are uniform in size, with a size of about 300nm. figure 2 The XRD picture of the octahedral cuprous oxide shows that the six peaks in the obtained product correspond to the (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com