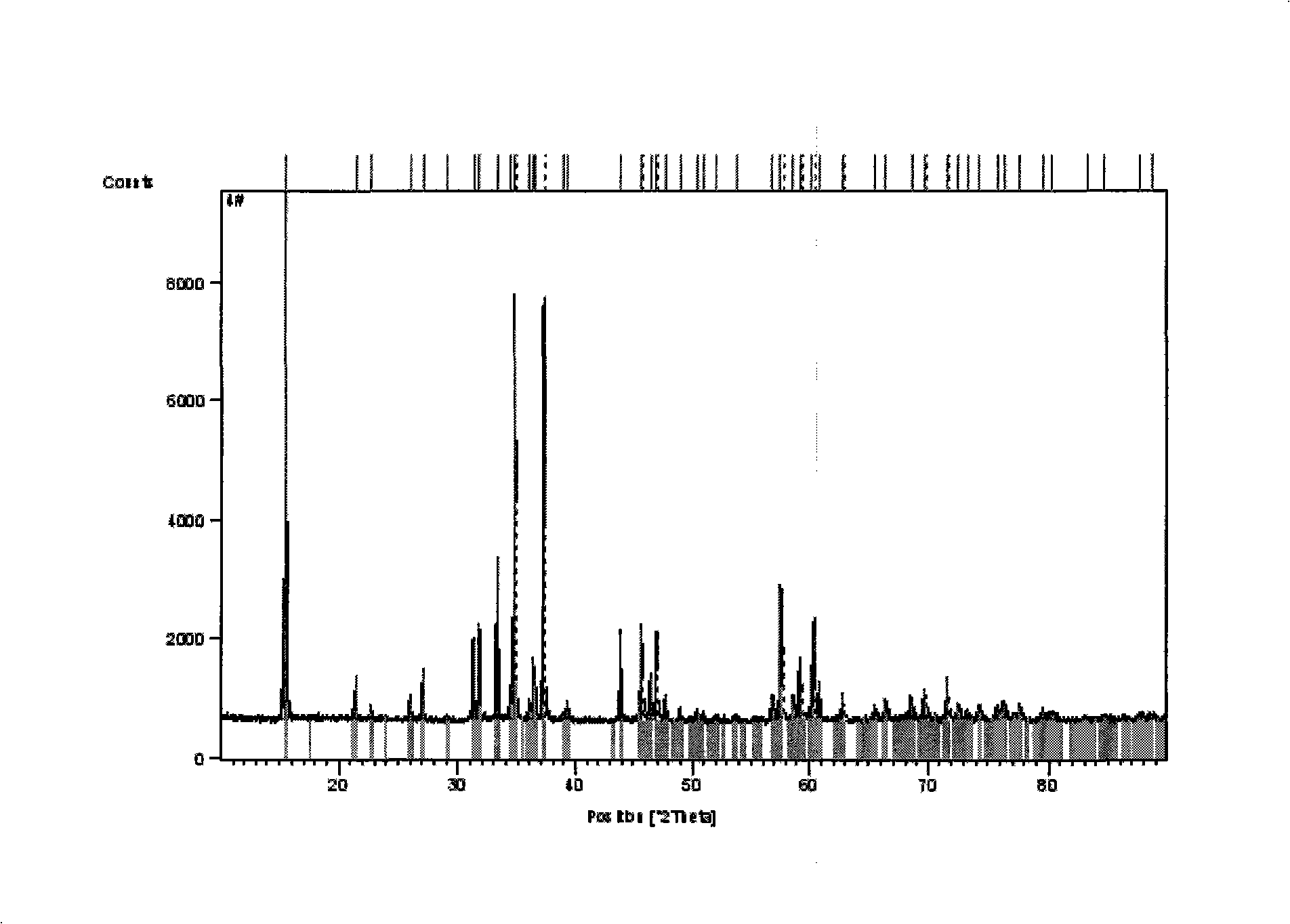

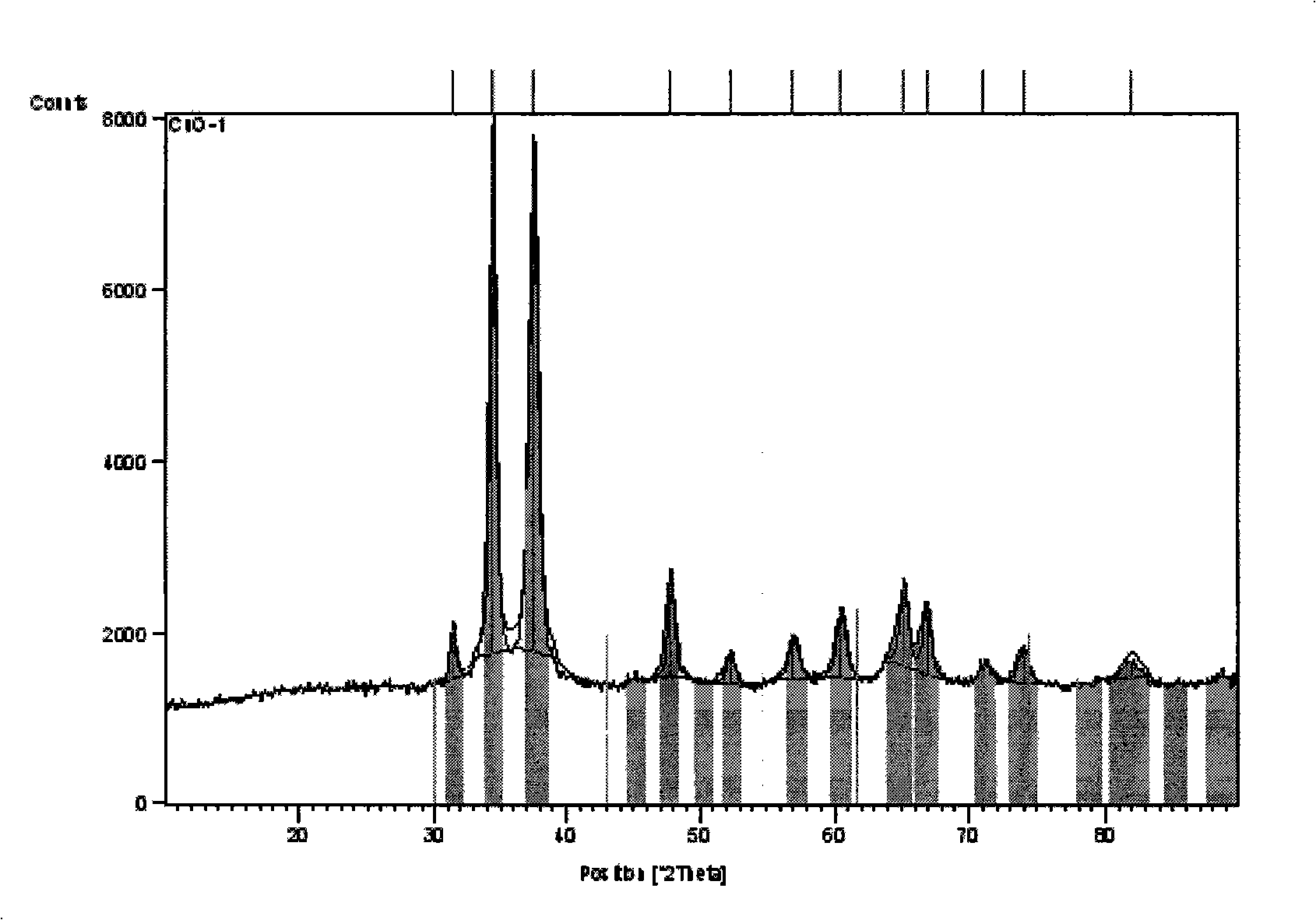

Method for preparing monoclinic system crystalline state cupric oxide and uses thereof

A monoclinic and copper oxide technology, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of difficult separation of water-soluble salts, restrictions on the industrial production of copper oxide, complete separation of difficult copper oxide, etc., and achieve production costs Low, good fluidity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

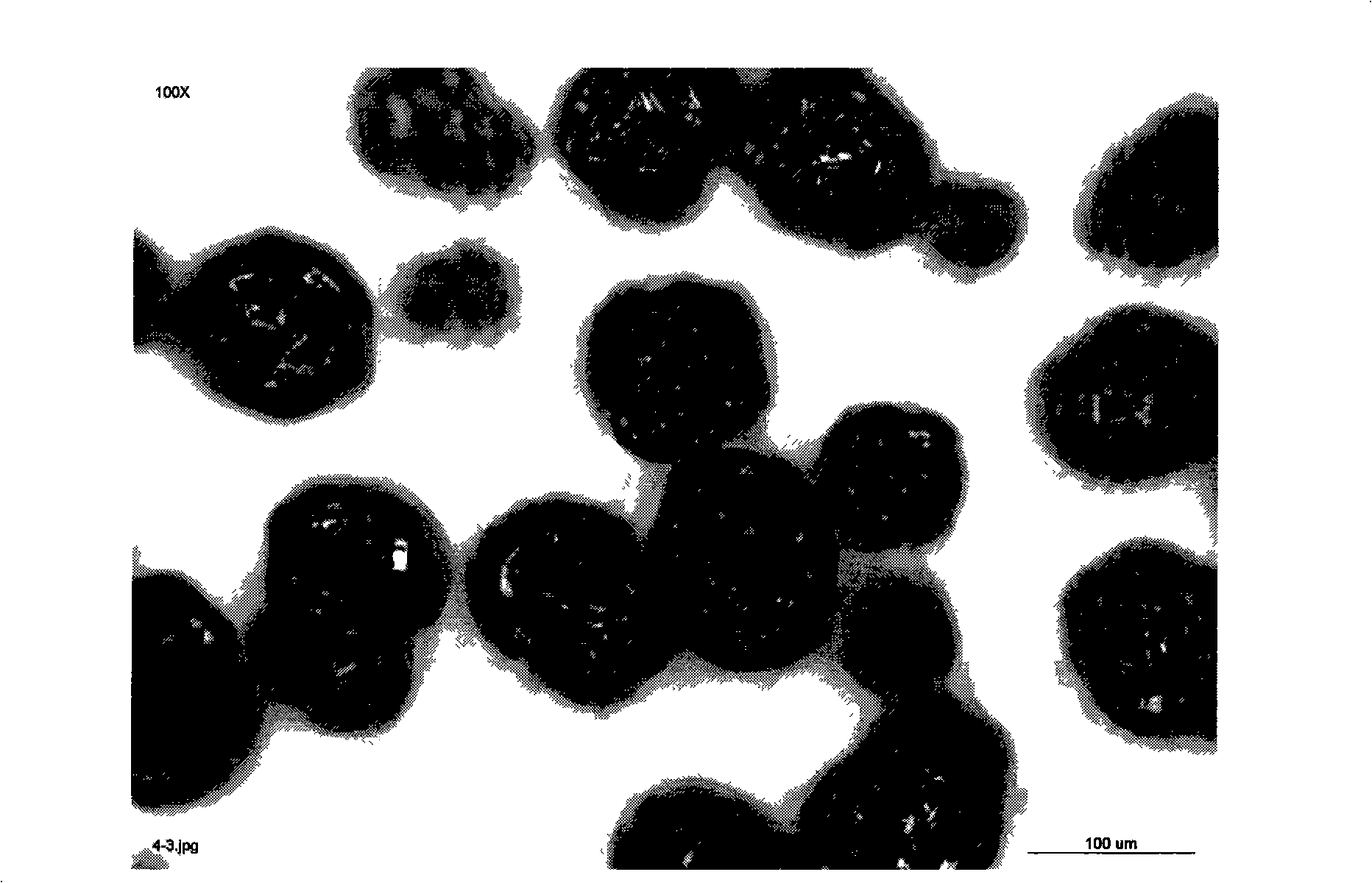

[0032] 1. Preparation of crystalline basic copper chloride

[0033] Take 400 kg of industrial grade solid ammonium chloride and add 8M 3 In the FRP reaction tank, inject 1500 liters of tap water, stir while passing steam to dissolve ammonium chloride and preheat to 75°C, add a small amount of water to 2M 3 . In addition, the copper content of 150 g / liter, the refined acidic copper chloride etching waste liquid with a pH value of 2 and 6% ammonia water were each 3.0M 3 , respectively preheated to 70-75°C in their respective raw material storage tanks. Start the stirring paddle of the reaction tank, open the raw material pumps of copper waste liquid and ammonia water and adjust the flow rate of the flowmeter at the same time, so that the two are added to the reaction tank at a speed of about 100 liters per minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com