Corrosive agent for displaying silicon steel coagulation tissue and its preparation method

A solidification structure and corrosive agent technology, applied in the field of metallographic inspection, can solve the problems of inconvenient operation of continuous casting slab samples, difficulty in achieving ideal results, and dendrite morphology damage, etc., to achieve strong interaction constraints and dendrite display effects Good, simplified operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

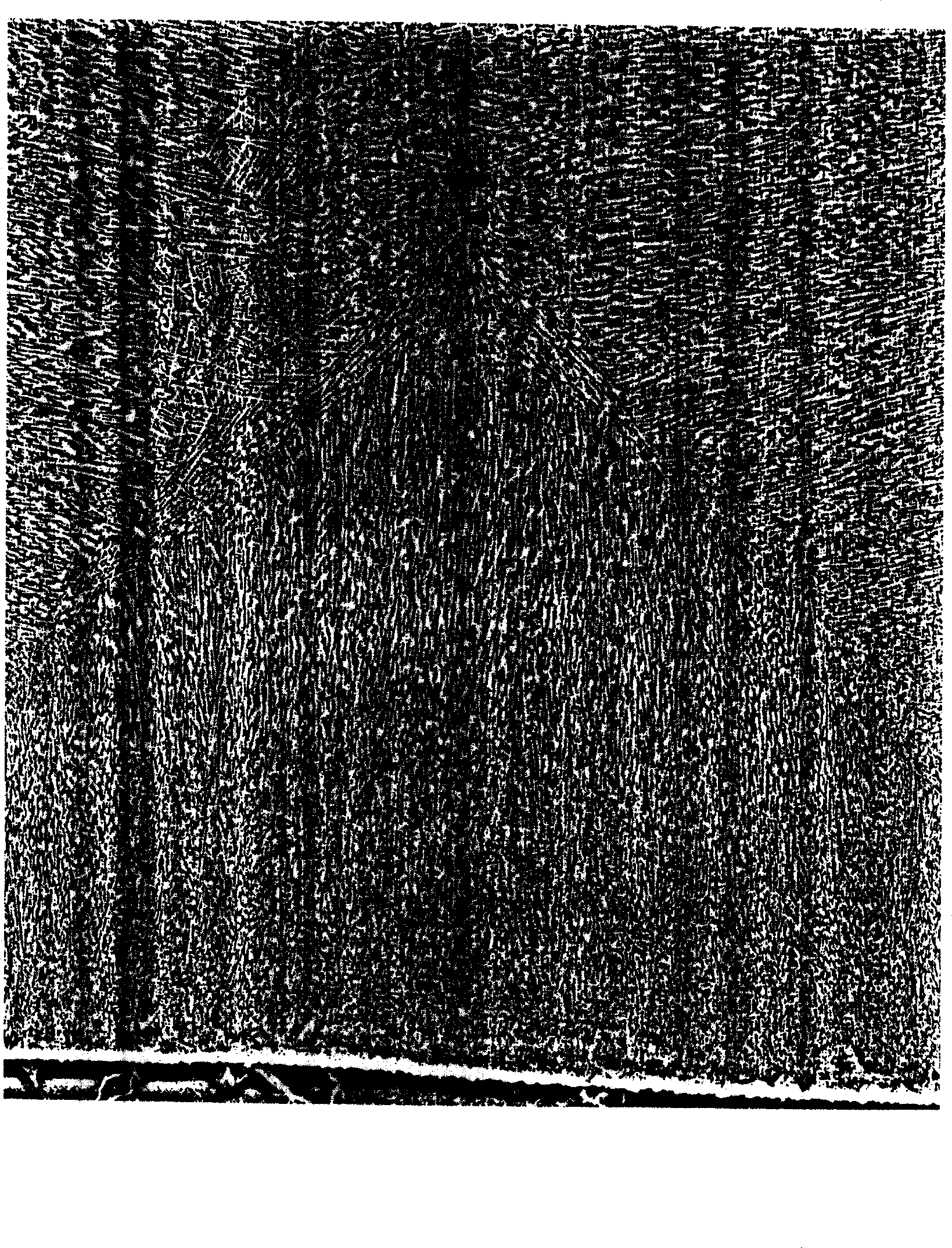

Image

Examples

Embodiment Construction

[0021] The embodiment of the present invention provides three corresponding silicon steel continuous casting slab dendritic macroscopic corrosive agents for the dendrite morphology of three different Si-containing silicon steels, and the formula is as follows:

[0022] For the dendrite morphology of silicon steel with Si content <0.6% and trace alloy elements:

[0023] 1.2 grams of picric acid 12 grams of ferric chloride

[0024] Absolute ethanol (99.5%) 40ml Cupric chloride 0.4g

[0025] Hydrochloric acid (36% ~ 38%) 15 ml magnesium chloride 0.3 g

[0026] 100ml distilled water

[0027] For the dendrite morphology of silicon steel containing 0.6% to 1.5% Si and containing trace alloying elements:

[0028] 10 grams of ferric chloride 1.2 grams of stannous chloride

[0029] 50 ml of absolute ethanol (99.5%) 0.3 g of copper chloride

[0030] Hydrochloric acid (36% ~ 38%) 15 ml magnesium chloride 0.3 g

[0031] 100ml distilled water

[0032] For the dendrite morphology ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com