Method for recovery processing of ammonia nitrogen from printed circuit board waste liquid

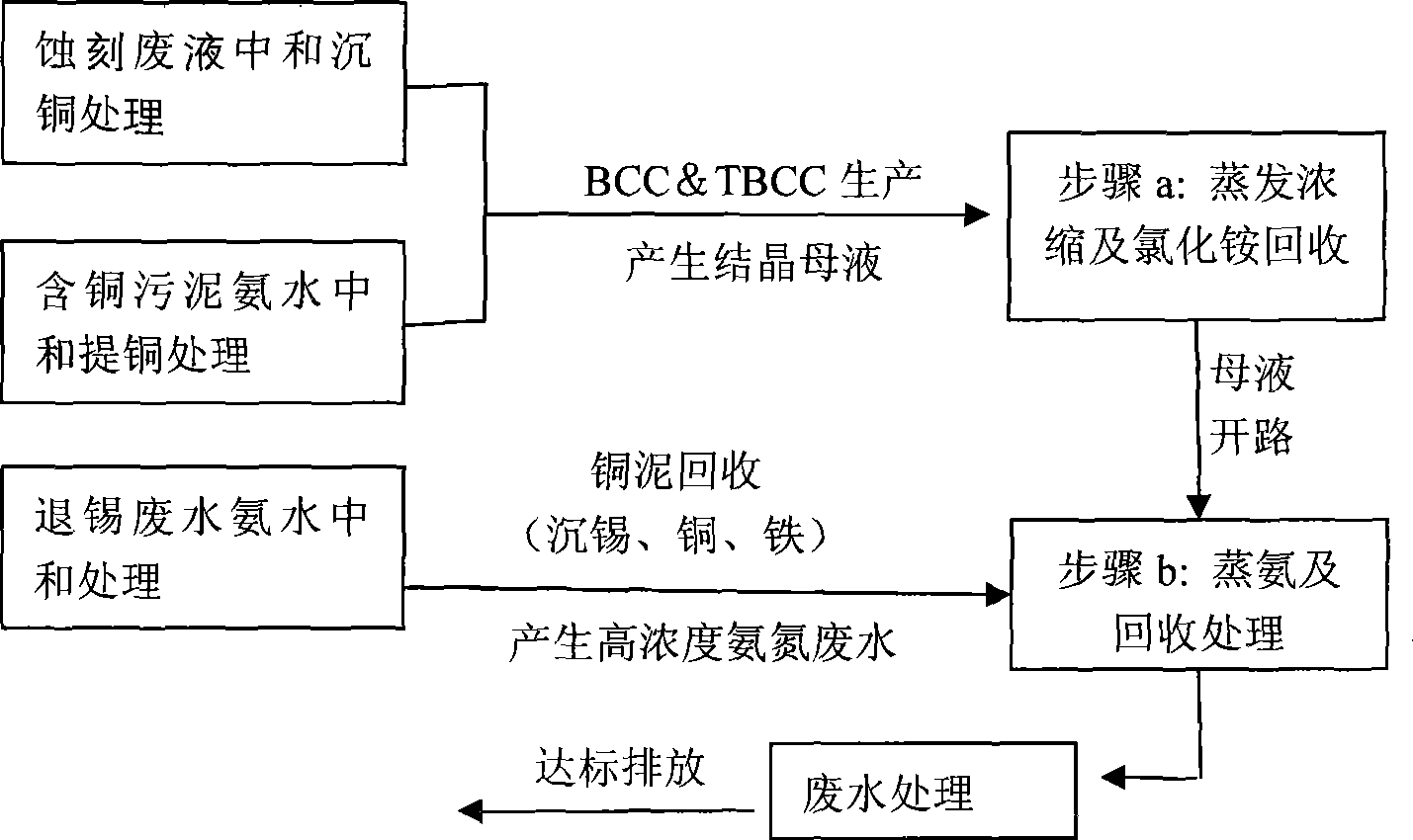

A printed circuit board, ammonia nitrogen recovery technology, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of lack of pertinence and safety applicability, and achieve resource utilization, High efficiency and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

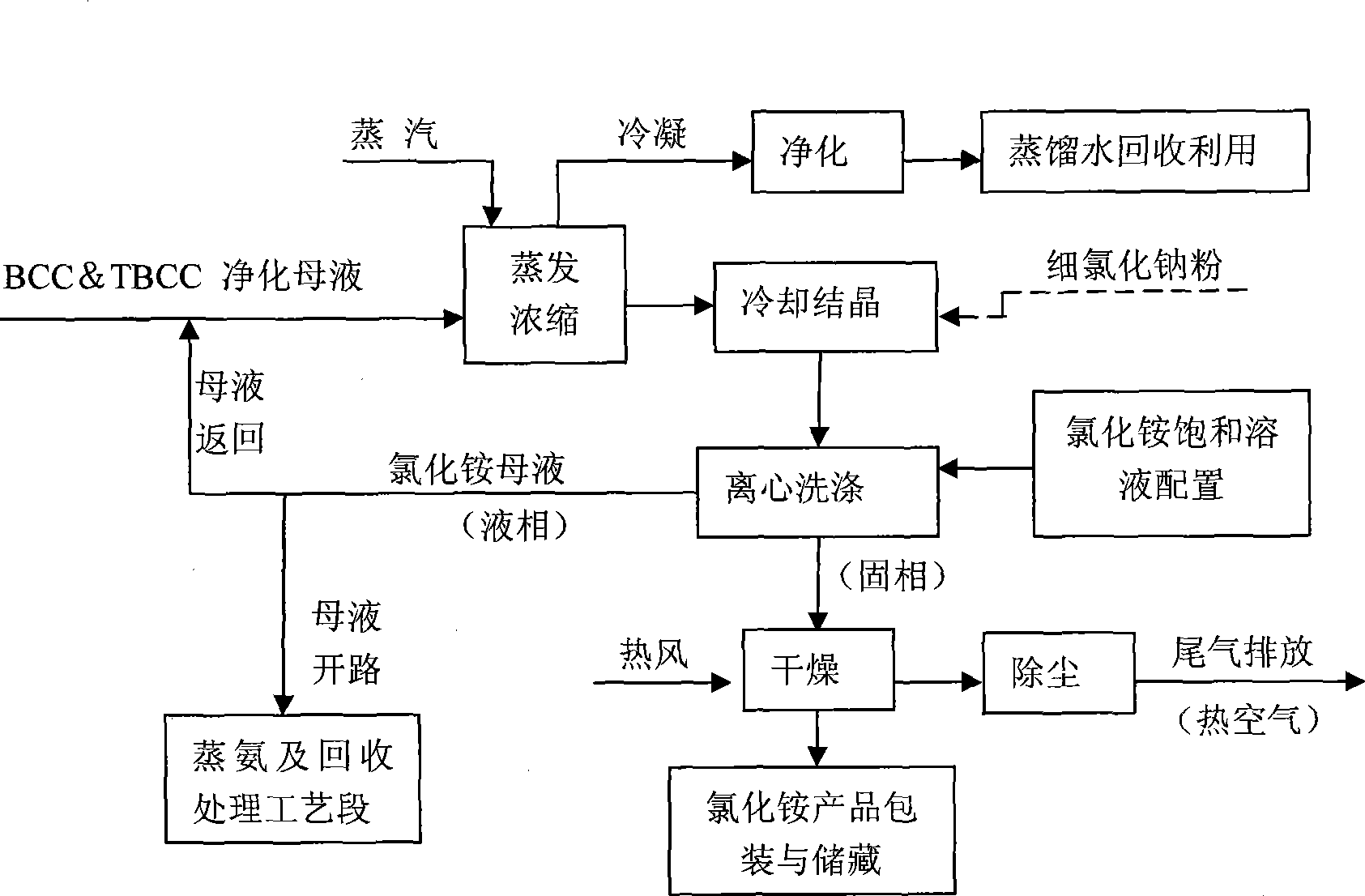

[0049] BCC, TBCC crystallization mother liquor MED-TC 5-effect evaporation and ammonium chloride recovery.

[0050] A kind of acidic etching waste liquid derived from circuit board factory A, its phase analysis is shown in Table 1, and a kind of alkaline etching waste liquid derived from circuit board factory B, its phase analysis is shown in Table 2, and neutralized and precipitated Copper is treated to obtain copper ammonia liquid; a kind of copper-containing sludge derived from circuit board factory C, its phase analysis is shown in Table 3, copper is extracted through ammonia water, and copper ammonia liquid is also obtained. Mix the two copper ammonia liquids to further produce BCC and TBCC.

[0051] Phase name HCl CuCl 2 CuCl NaCl NH 4 Cl other additives Content g / l 80 200 15 100 8 5

[0052] Table 1

[0053]

Phase name

NH 3

Cu 2+

Cl -

other additives

[0054] Content g / l 140...

Embodiment 2

[0061] BCC, TBCC crystallization mother liquor MVC+MED-TC two-stage combined process evaporation and ammonium chloride recovery.

[0062] A kind of acidic etching waste liquid derived from circuit board factory D, its phase analysis is shown in Table 4, and a kind of alkaline etching waste liquid derived from circuit board factory E, its phase analysis is shown in Table 5, and neutralized and precipitated Copper treatment to obtain cuproammonia liquid; further production of BCC and TBCC.

[0063] Phase name HCl CuCl 2 CuCl NaCl NH 4 Cl other additives Content g / l 75 198 16 98 10 5

[0064] Table 4

[0065] Phase name NH 3 Cu 2+ Cl - other additives

[0066] Content g / l 136 85 76 0~10

[0067] table 5

[0068] In the process of producing BCC and TBCC, high ammonia nitrogen wastewater containing ammonium chloride is produced, containing 40g / l of ammonia nitrogen, 25mg / l of copper, 50mg / l of nick...

Embodiment 3

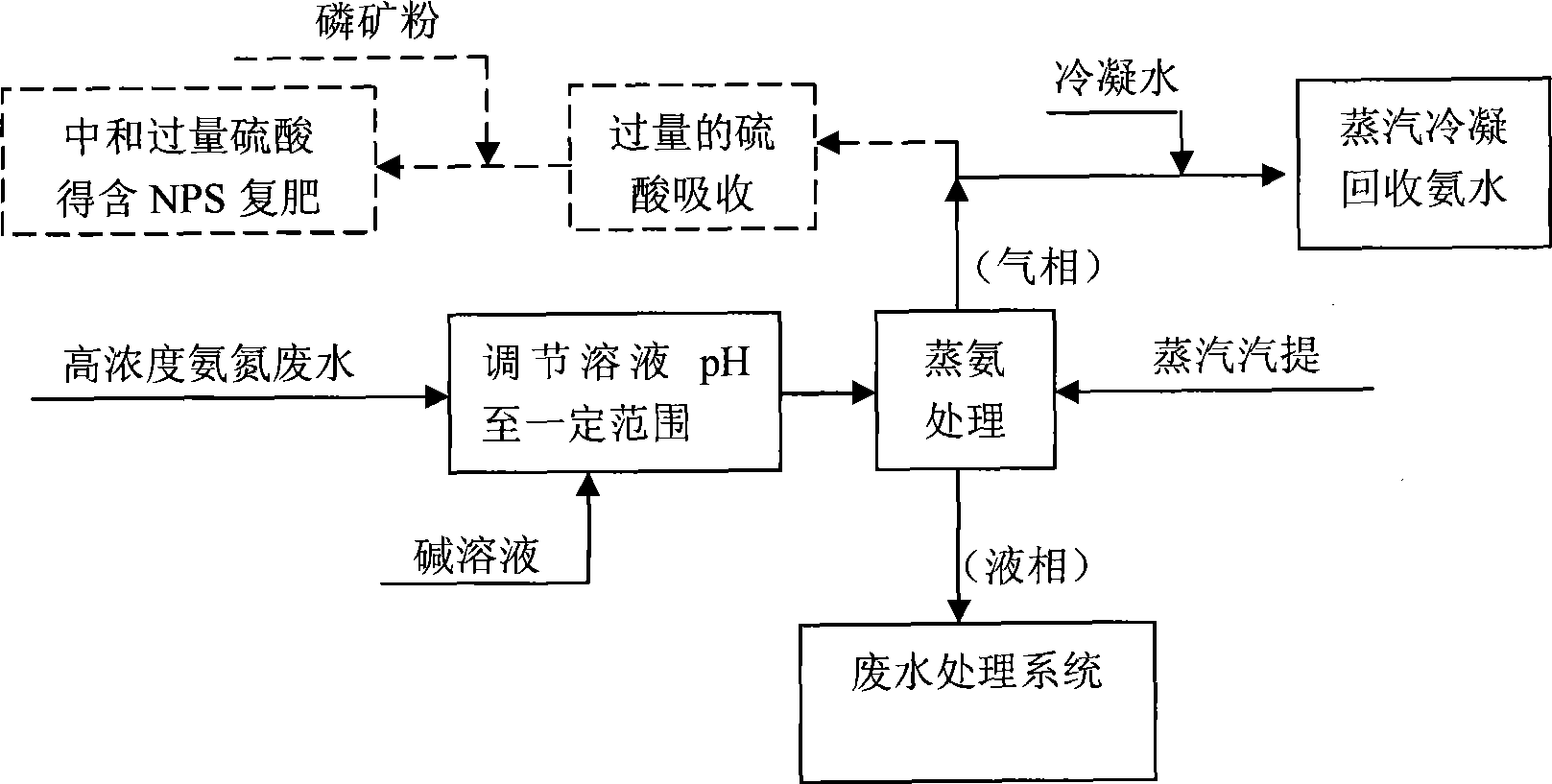

[0071] Ammonia is distilled using sub-boiling technology and absorbed with sulfuric acid as the medium.

[0072] Collect the wastewater produced by the F tin stripping process of a circuit board factory, containing Sn107.00g / l, Cu45.75g / l, Pb53.00, Fe27.55g / l. The waste water is neutralized with industrial ammonia water, heavy metal elements such as Sn, Cu, Pb, Fe are precipitated, and after pressure filtration, the precipitate—tin sludge is used as the raw material for the production of sodium stannate. The waste water contains 18.6 g / l of ammonia nitrogen.

[0073] The tin stripping waste water is mixed with the ammonium nitrogen waste water produced by neutralizing the ammonia nitrogen waste water in ammonia water and reclaiming the ammonium chloride split from the BCC and TBCC crystallization mother liquid to obtain waste water with an ammonia nitrogen concentration of 28.5g / l, and use ammonia water and NH 4 Cl to prepare NH with a pH of 10.5-12.0 4 Cl—NH 3 .H 2O buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com