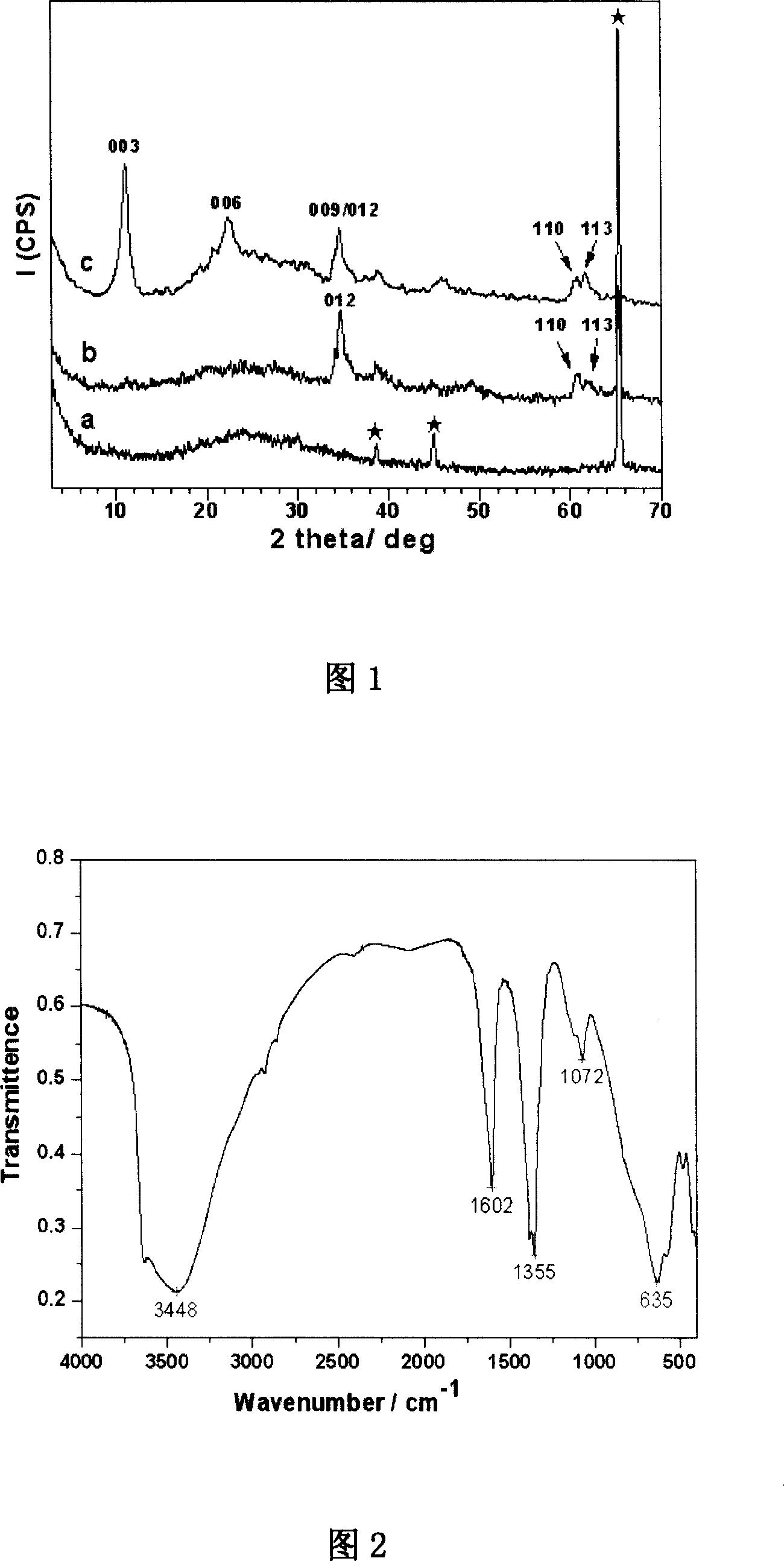

Vertically oriented hydrotalcite film in nano and micron composite structure and its preparing process

A composite structure and vertical orientation technology, applied in chemical instruments and methods, catalyst activation/preparation, aluminum compounds, etc., can solve the problems of poor thermal stability of the substrate, shedding, poor crystal orientation of LDHs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

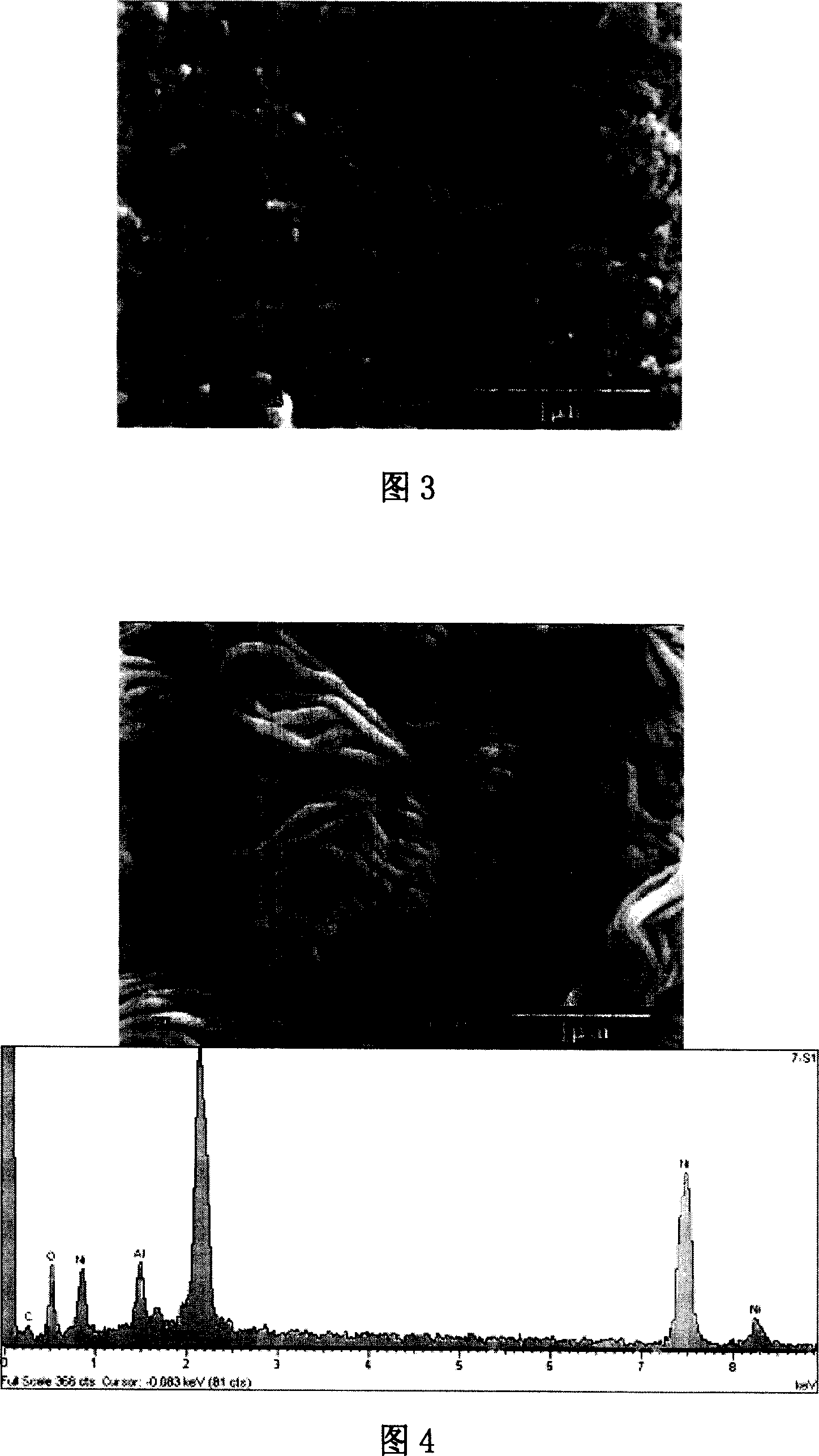

Embodiment 1

[0031] The aluminum sheet with a thickness of 0.1mm (purity is 99.5%) was ultrasonically cleaned with ethanol for 5 minutes, then ultrasonically cleaned with water for 5 minutes to remove surface oil, and then anodized on an anodizing device for 50 minutes, and the aluminum sheet was taken out and rinsed with deionized water Electrolyte, obtain the anodized aluminum sheet for subsequent use. The anodizing device uses a lead plate or a stainless steel plate as the cathode, and the electrolyte is 1.0mol L -1 sulfuric acid solution, the oxidation current is 2A.

[0032] In a 1L Erlenmeyer flask, 1mol Ni(NO 3 ) 2 ·6H 2 O and 6mol NH 4 NO 3 Dissolve in deionized water, and adjust the pH of the solution to 7.5 with 1% dilute ammonia water.

[0033] Suspend the anodized aluminum substrate in the solution, seal the container, and react at a constant temperature of 120°C for 6 hours. After the reaction is completed, take out the aluminum substrate, rinse it with deionized water, ...

Embodiment 2

[0036] Ultrasonic cleaning of an aluminum sheet with a thickness of 0.05 mm (purity of 99%) with ethanol for 10 minutes, then ultrasonic cleaning with water for 10 minutes to remove surface oil, and then anodize on an anodizing device for 30 minutes, take out the aluminum sheet, and rinse off the electrolysis with deionized water. solution to obtain anodized aluminum sheets for later use. The anodizing device uses a lead plate or a stainless steel plate as the cathode, and the electrolyte is 1.0mol L -1 sulfuric acid solution, the oxidation current is 2A.

[0037] In a 1L Erlenmeyer flask, 1mol Ni(NO 3 ) 2 ·6H 2 O and 3mol NH 4 NO 3 Dissolve in deionized water, and adjust the pH of the solution to 5.5 with 1% dilute ammonia water.

[0038] Suspend the anodized aluminum substrate in the solution, seal the container, and react at a constant temperature of 75°C for 36 hours. After the reaction, take out the aluminum substrate, rinse it with deionized water, and dry it at 40...

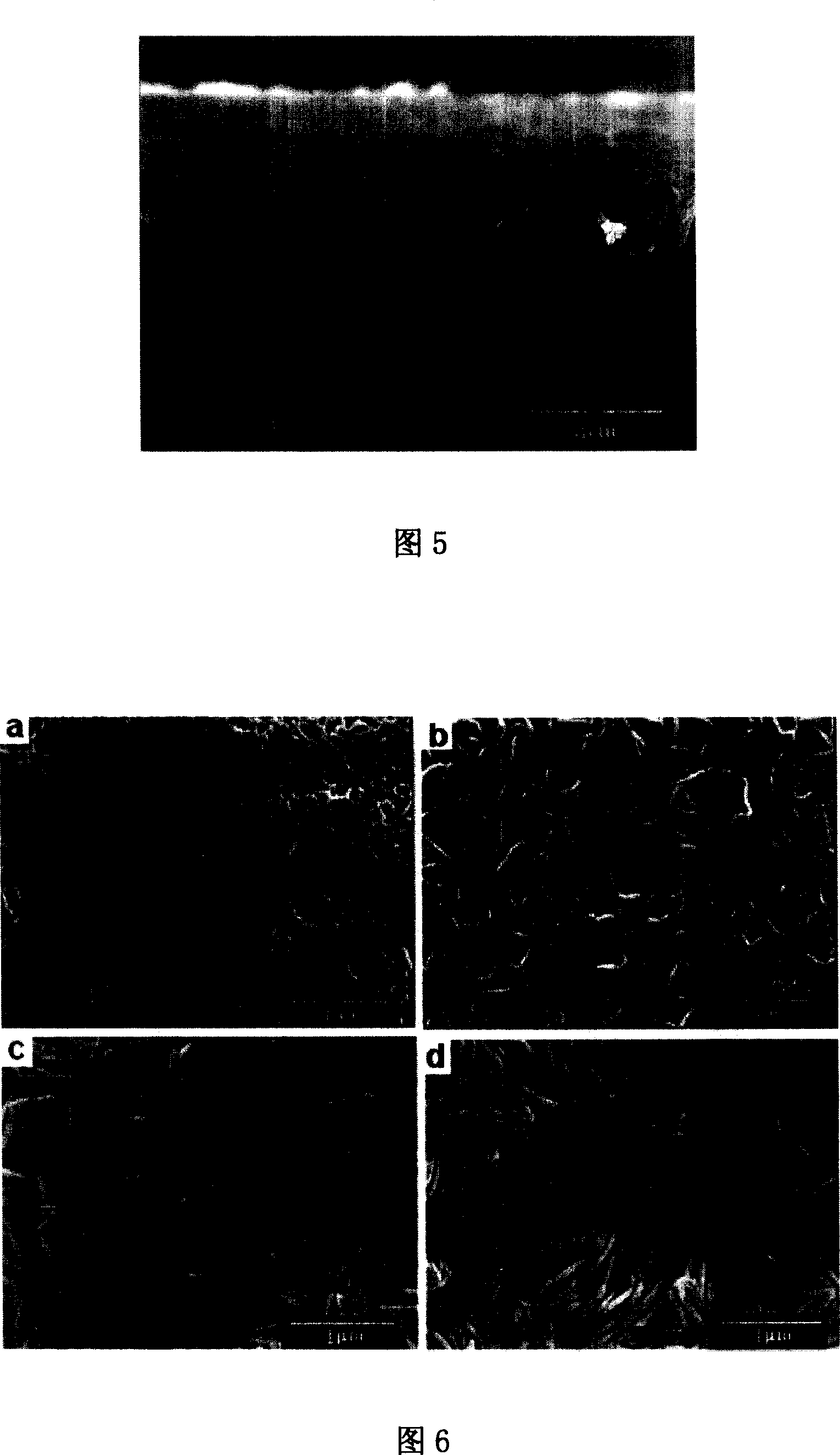

Embodiment 3

[0041] 4 pieces of aluminum sheets with a thickness of 0.1mm and a purity of 99.5% were ultrasonically cleaned with ethanol for 5 minutes, then ultrasonically cleaned with water for 5 minutes to remove surface oil, and then anodized on an anodizing device for 50 minutes, and the aluminum sheets were taken out and rinsed with deionized water Electrolyte, obtain the anodized aluminum sheet for subsequent use. The anodizing device uses a lead plate or a stainless steel plate as the cathode, and the electrolyte is 1.0mol L -1 sulfuric acid solution, the oxidation current is 2A.

[0042] In a 1L Erlenmeyer flask, 1mol Ni(NO 3 ) 2 ·6H 2 O and 3mol NH 4 NO 3 Dissolve in deionized water, and adjust the pH of the solution to 7.0 with 1% dilute ammonia water.

[0043] Suspend 4 pieces of anodized aluminum substrates in the solution, seal the container, and react at a constant temperature at 100°C, take out a piece of aluminum substrate at 6, 12, 18, and 24 hours respectively, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com