Method for prepn. of electrode catalyst with function of anti-CD and contg. platinum and ruthenium series carried on carbon nanometer tube

A technology of electrode catalysts and carbon nanotubes, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poisoning and battery performance degradation, and achieve good dispersion, small size, high The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

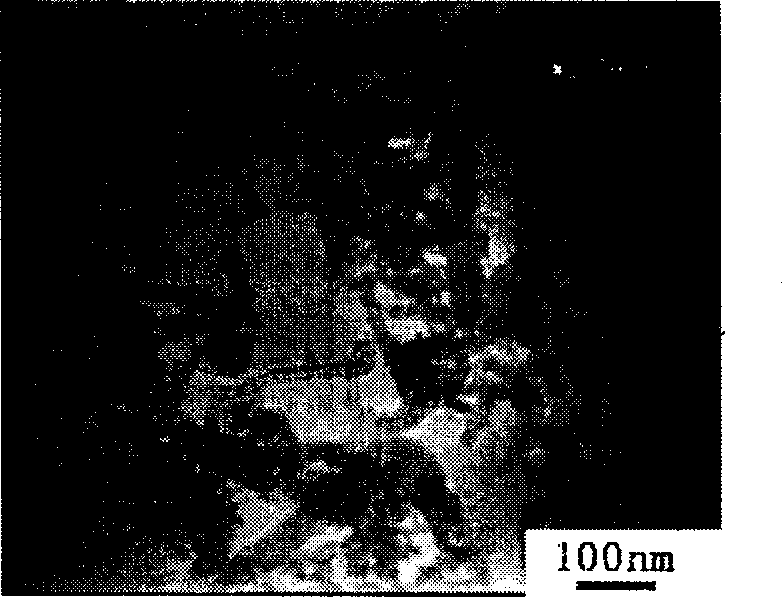

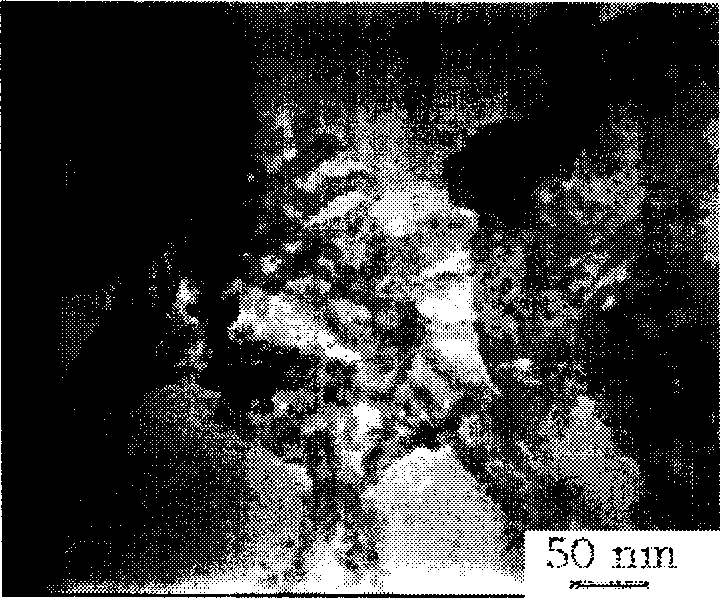

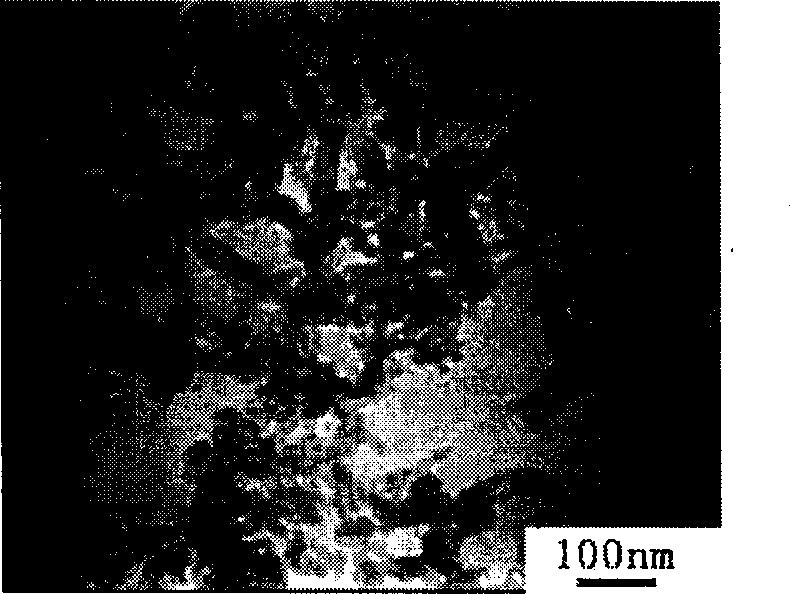

Image

Examples

Embodiment 1

[0040] 1. Activation treatment of nanotubes (provided by the Department of Chemical Engineering, Tsinghua University)

[0041] ·Water washing: put carbon nanotubes into a round bottom flask, wet it with absolute ethanol, add a certain amount of double distilled water, heat to boil, reflux for 1 hour, filter, and dry at 80°C for 2 hours to obtain water-washed activated carbon nanotube samples .

[0042] Pickling: soak the water-washed activated carbon nanotube sample with 10% hydrochloric acid for 10 hours, reflux for 1 hour, filter, and wash with water until there is no Cl - Dry in vacuum at 80°C for 2 hours.

[0043] 2. Preparation of Pt-Ru / CNTs catalyst by in situ chemical reduction homogeneous deposition method

[0044] Raw material ratio: Pt:Ru=1:0.5

[0045] (1) Preparation of complex ions (ie complex ions)

[0046] ① Take chloroplatinic acid aqueous solution and add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution is adjusted to pH=5;

[0047]...

Embodiment 2

[0055] 1. Activation treatment of carbon nanotubes (provided by the Department of Chemical Engineering, Tsinghua University), as above.

[0056] 2. Preparation of Pt-Sn / CNTs catalyst by in situ chemical reduction homogeneous deposition method

[0057] Raw material ratio Pt:Sn=1:1

[0058] (1) Preparation of complex ions (ie complex ions)

[0059] ① Take chloroplatinic acid aqueous solution and add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution is adjusted to pH=5;

[0060] ② Take another SnCl 2 Add a small amount of concentrated HCl to the solution, add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution was adjusted to pH=5.

[0061] (2) Preparation of metastable colloids

[0062] Mix the above ① and ② complex ion solutions together, and slowly add H 2 o 2 , adjusted to pH=5 with 5% NaOH solution.

[0063] (3) Homogeneous in-situ chemical reduction deposition

[0064] Add activated carbon nanotubes to the metastable colloid...

Embodiment 3

[0068] 1. Activation treatment of carbon nanotubes (provided by the Department of Chemical Engineering, Tsinghua University), as above.

[0069] 2. Preparation of Pt-Ru-H by in-situ chemical reduction homogeneous deposition method x WO y / CNTs catalyst

[0070] Raw material ratio Pt: Ru: H x WO y =1:1:1

[0071] (1) Preparation of complex ions (ie complex ions)

[0072] ① Take chloroplatinic acid aqueous solution and add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution was adjusted to pH=5; another RuCl 3 Add a small amount of concentrated HCl to the solution, add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution was adjusted to pH=5.

[0073] ② Take another Na 2 WO 4 Add a small amount of concentrated HCl to the solution, add NaHSO 3 powder, stirred for 20 minutes, added Na 2 CO 3 The solution was adjusted to pH=5.

[0074] (2) Preparation of metastable colloids

[0075] Mix the above ①②③ ion solutions together, slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com