Method for recycling lead oxide from lead plaster of waste lead-acid storage battery

A technology of lead-acid batteries and lead oxide, applied in battery recycling, lead monoxide, lead oxide, etc., can solve the problems of increased energy consumption, slow reaction speed, large consumption, etc., and achieve high atom economy, short process flow, The environmental protection effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

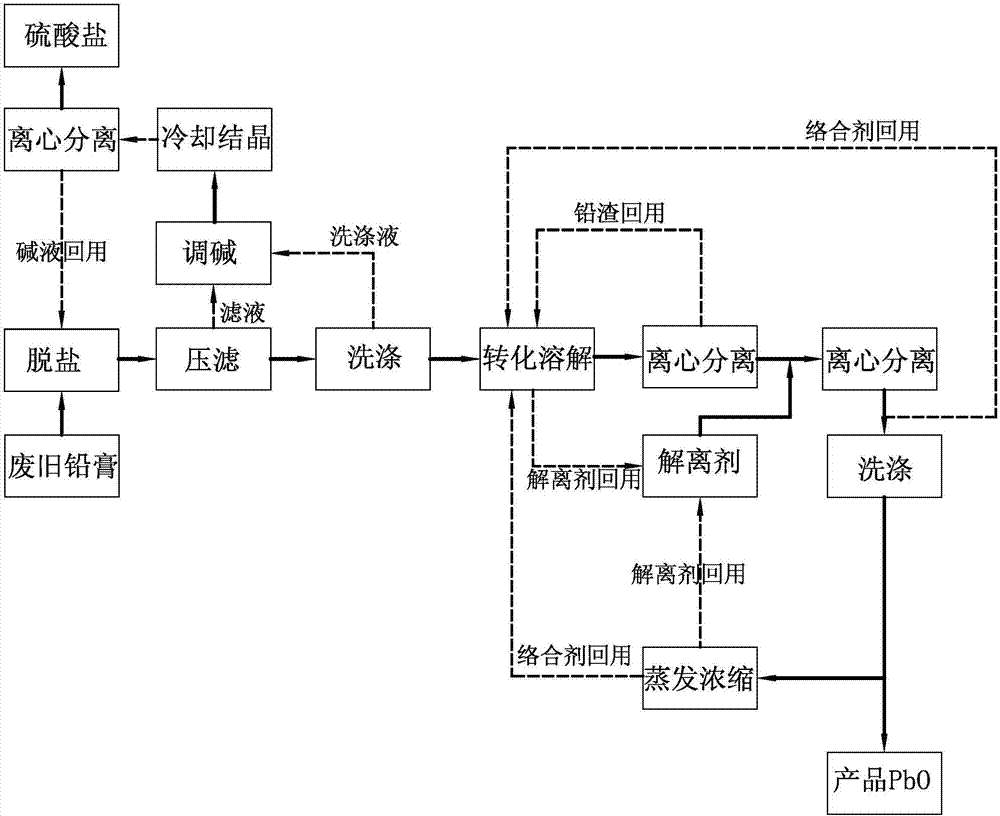

[0049] according to figure 1 In the process flow shown, take the lead paste of waste lead-acid batteries, then add excess 10wt% NaOH as lye, control the treatment temperature to 35°C, the treatment time to 20min, and the stirring speed to 120rad / min. After the lead plaster is treated with lye, the solid-liquid separation is carried out to obtain the pre-desalted lead paste and the desalted mother liquor mainly composed of sodium acid. After washing the obtained desalted lead plaster, weigh 1 kg of lead plaster and add it to the first reaction kettle, and simultaneously add excessive broken lead grids, 15 g of antimony oxide as a catalyst, a sufficient amount of 0.5 mol / L ethylenediaminetetraacetic acid, Propylenediaminediacetic acid or its sodium salt aqueous solution was used as a complexing agent, and stirred at a constant temperature of 60°C for 2 hours. The mixture obtained after the reaction is filtered and separated to obtain a lead-containing solution and a filter resi...

Embodiment 2

[0052] according to figure 1 In the process flow shown, take the lead paste of waste lead-acid batteries, then add an excess of 15wt% KOH as lye, control the treatment temperature at 45°C, the treatment time is 10min, and the stirring speed is 80rad / min. After the lead plaster is treated with lye, the solid-liquid separation is carried out to obtain the pre-desalted lead paste and the desalted mother liquor mainly composed of sodium acid. After washing the obtained desalted lead plaster, weigh 1 kg of lead plaster and add it to the first reaction kettle, add excessive broken lead grid, 10 g of copper oxide as catalyst, and a sufficient amount of 1mol / L lysine aqueous solution as complexing agent, and stirred for 2 hours at a constant temperature of 80°C. The mixture obtained after the reaction is filtered and separated to obtain a lead-containing solution and a filter residue. Wherein the lead-containing solution is transferred into the second reaction kettle. Stir at a con...

Embodiment 3

[0055] according to figure 1 As shown in the technological process, take the waste lead-acid storage battery lead paste, then add excessive 20wt% NH 4 OH is lye, the treatment temperature is controlled at 25°C, the treatment time is 30min, and the stirring speed is 90rad / min. After the lead plaster is treated with lye, the solid-liquid separation is carried out to obtain the pre-desalted lead paste and the desalted mother liquor mainly composed of sodium acid. After washing the obtained desalted lead plaster, weigh 1kg of lead plaster and add it to the first reaction kettle, add excessive broken lead grid, 15g tin dioxide as catalyst, and sufficient 0.5mol / L tryptophan aqueous solution as catalyst. complexing agent, stirred for 1 hour at a constant temperature of 100°C. The mixture obtained after the reaction is filtered and separated to obtain a lead-containing solution and a filter residue. Wherein the lead-containing solution is transferred into the second reaction kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com