Nickel-cobalt-aluminum ternary precursor as well as preparation method thereof and preparing anode material and method

A positive electrode material, nickel-cobalt-aluminum technology, applied in the field of preparation of lithium-ion battery positive electrode materials and their precursor materials, can solve problems affecting the reaction speed of co-precipitation, achieve the effect of avoiding local enrichment and improving tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

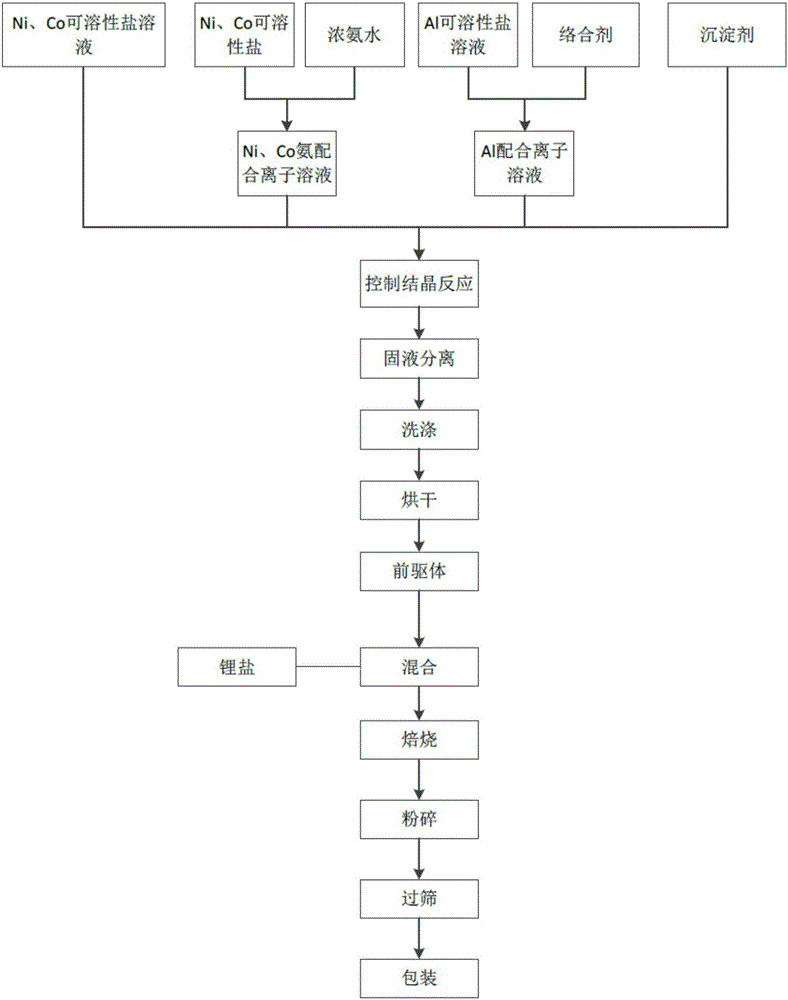

Method used

Image

Examples

Embodiment 1

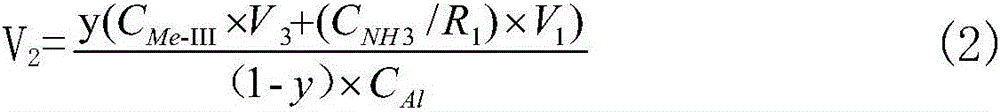

[0052] Take ammonia water with a concentration of 10mol / L, add nickel sulfate and cobalt sulfate according to the ratio of 368.9g of nickel sulfate and 74.0g of cobalt sulfate per liter of ammonia water, stir to dissolve nickel sulfate and cobalt sulfate, and prepare ammonia complex ions of Ni and Co Solution (Solution I), by 81.9g NaAlO per liter 2 The ratio preparation sodium metachlorate solution (solution II), preparation 6mol / L sodium hydroxide solution (solution IV), prepares the mixed salt solution of nickel sulfate and cobalt sulfate according to the ratio of Ni / Co=0.842 / 0.158, the total salt solution The concentration is 2.5mol / L (Solution III). Four kinds of solutions are added in the reaction kettle concurrently, wherein the flow velocity of nickel-cobalt salt solution (solution III) is 100ml / min, obtains nickel, cobalt complex ion solution flow velocity by formula (1) and is 30ml / min, by formula (2 ) to obtain the sodium metaaluminate solution flow rate is 15.8ml / ...

Embodiment 2

[0055] Take ammonia water with a concentration of 10mol / L, add nickel sulfate 406.5g and cobalt sulfate 33.80g per liter of ammonia water, add nickel sulfate and cobalt sulfate, stir to dissolve nickel sulfate and cobalt sulfate, and prepare ammonia complex ions of Ni and Co Solution (Solution I), 163.9 g NaAlO per liter 2 The ratio preparation sodium metachlorate solution (solution II), preparation 6mol / L sodium hydroxide solution (solution IV), prepares the mixed salt solution of nickel sulfate and cobalt sulfate according to the ratio of Ni / Co=0.928 / 0.072, the total salt solution The concentration is 2.3mol / L (Solution III). Four kinds of solutions are added in the reaction kettle concurrently, wherein the flow velocity of nickel-cobalt salt solution (solution III) is 200ml / min, obtain nickel, cobalt complex ion solution flow velocity V by formula (1) 1 Be 48ml / min, obtain sodium metaaluminate solution flow velocity V by formula (2) 2 Be 25.3ml / min, adjust the flow rate o...

Embodiment 3

[0058] Preparation of Ni 0.98 co 0.01 Al 0.01 (OH) 2 Precursor: get concentration and be the ammoniacal liquor of 15mol / L, add nickelous sulfate and cobaltous sulfate according to the ratio of adding nickel sulfate 390.3g and cobaltous sulfate 4.3g per liter of ammoniacal liquor, stir nickel sulfate and cobaltous sulfate dissolve, prepare Ni, Co Ammonia complex ion solution (solution I), according to 245.9g NaAlO per liter 2The ratio preparation sodium metachlorate solution (solution II), preparation 10mol / L sodium hydroxide solution (solution IV), prepares the mixed salt solution of nickel sulfate and cobalt sulfate according to the ratio of Ni / Co=0.928 / 0.072, the total salt solution The concentration is 2.3mol / L (Solution III). Four kinds of solutions are added in the reaction kettle concurrently, wherein the flow rate of nickel-cobalt salt solution (solution III) is 150ml / min, obtain nickel, cobalt complex ion solution flow rate V by formula (1) 1 Be 48ml / min, obtain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com