Low-temperature sintering high performance soft magnetic ferrite material and manufacturing method

A ferrite material, low-temperature sintering technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of large power consumption and N2 gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

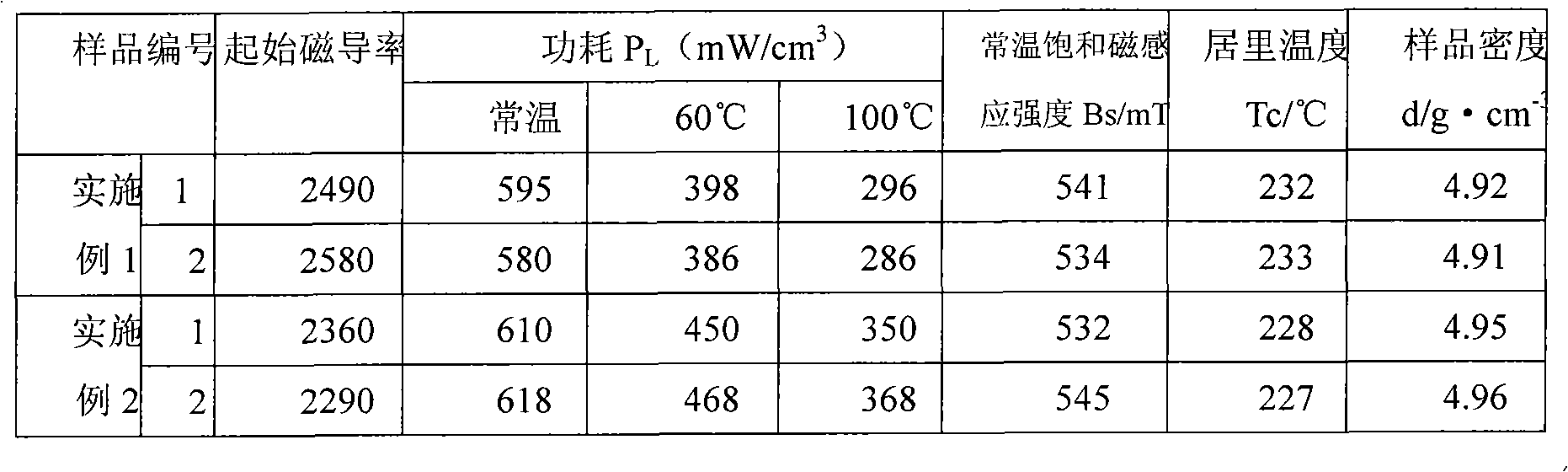

Embodiment 1

[0021] According to the following formula: Fe 2 o 3 : 53.1mol%, ZnO: 11.2mol%, MnO: 35.7mol% (the raw material form is Mn 3 o 4 ) to weigh raw materials; put them into a sand mill pre-added with deionized water to grind, control the average particle size to 0.5±0.1μm, and after one spray granulation, pre-fire with an electric rotary kiln at a temperature of 850±30°C. Then the pre-fired material is put into a sand mill for secondary sand grinding. During the sand grinding process, 45% of pure water, 0.008% of dispersant and 0.005% of defoamer are added relative to the content of the main component, and the additive CaO: 0.045wt% is added. , SiO 2 : 0.008wt%, zinc metaborate: 0.025wt%. The average particle size of the controlled sand mill is 1.0±0.2μm. Finally, secondary spraying is carried out to obtain MnZn ferrite particle powder. Take the pellets and press them into φ25mm×φ15mm×7.5mm, the density is about 3.0±0.2g / cm 3 Put the ferrite blank into a bell furnace, and si...

Embodiment 2

[0023] According to the following formula: Fe 2 o 3 : 53.1mol%, ZnO: 11.2mol%, MnO: 35.7mol% (the raw material form is Mn 3 o 4) to weigh raw materials; put them into a sand mill pre-added with deionized water to grind, control the average particle size to 0.5±0.1μm, and after one spray granulation, pre-fire with an electric rotary kiln at a temperature of 850±30°C. Then the pre-fired material is put into a sand mill for secondary sand grinding. During the sand grinding process, 45% of pure water, 0.008% of dispersant and 0.005% of defoamer are added relative to the content of the main component, and the additive CaO: 0.045wt% is added. , SiO 2 : 0.008wt%, zinc metaborate: 0.03wt%. The average particle size of the controlled sand mill is 1.0±0.2μm. Finally, secondary spraying is carried out to obtain MnZn ferrite particle powder. Take the pellets and press them into φ25mm×φ15mm×7.5mm, the density is about 3.0±0.2g / cm 3 Put the ferrite blank into a bell furnace, and sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com