Preparation method of graphene coated electric-conductive fiber

A technology of conductive fiber and graphene, which is applied in the direction of carbon fiber, fiber treatment, natural fiber, etc., can solve the problems of uneven carbon black coating, easy to fall off, etc., and achieve the effect of improved conductivity, not easy to fall off, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] 1. Preparation of Graphene Hydrosol

[0040] Add graphite oxide or graphene oxide into deionized water at 1-5 mg / ml, and ultrasonically disperse for 15-30 minutes to obtain a stable and uniform graphene oxide aqueous solution. 0.5-1.5wt% of 80wt% hydrazine hydrate solution with a concentration of 80wt% is added dropwise to the graphene oxide solution, stirred evenly and then heated at 50° C. for 4 hours to obtain graphene hydrosol.

[0041]2. Preparation of graphene-coated conductive fibers

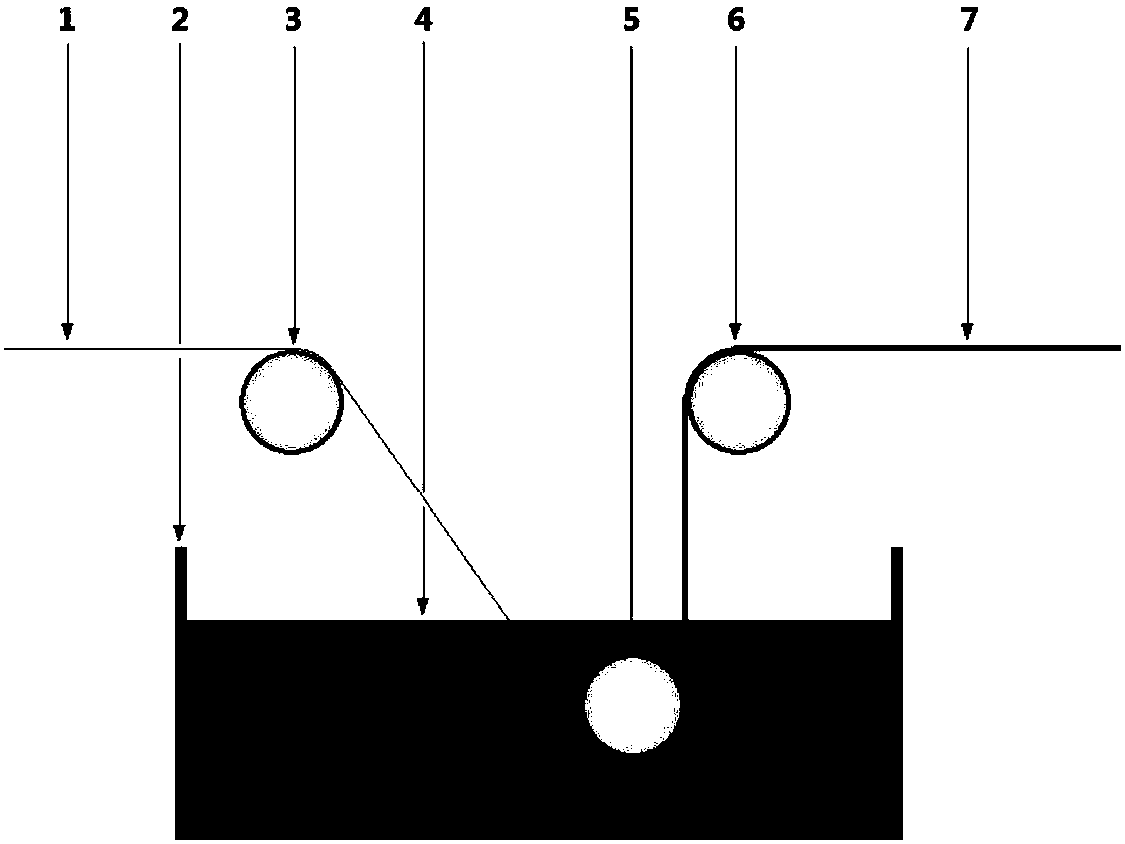

[0042] The dipping and pulling device used in the present invention is as figure 1 As shown, the technical parameters are as follows: the specifications of the fixed pulley I / II / III can be the same or different, and the diameter must be greater than 3cm; the liquid level of the graphene hydrosol in the liquid tank must be higher than the rotation axis of the fixed pulley II; The distance between Ⅱ and fixed pulley Ⅲ should be kept vertical, the angle between the tangent between f...

Embodiment 1

[0047] Take 200mg of graphite oxide, add it into 200ml of deionized water, and ultrasonically disperse for 20min to obtain an aqueous solution of graphene oxide. Add 2ml of hydrazine hydrate aqueous solution with a concentration of 80wt% dropwise to the graphene oxide aqueous solution, stir evenly and place it in a 50°C oven for heating for 4h, pour the obtained graphene hydrosol into figure 1 in the liquid tank.

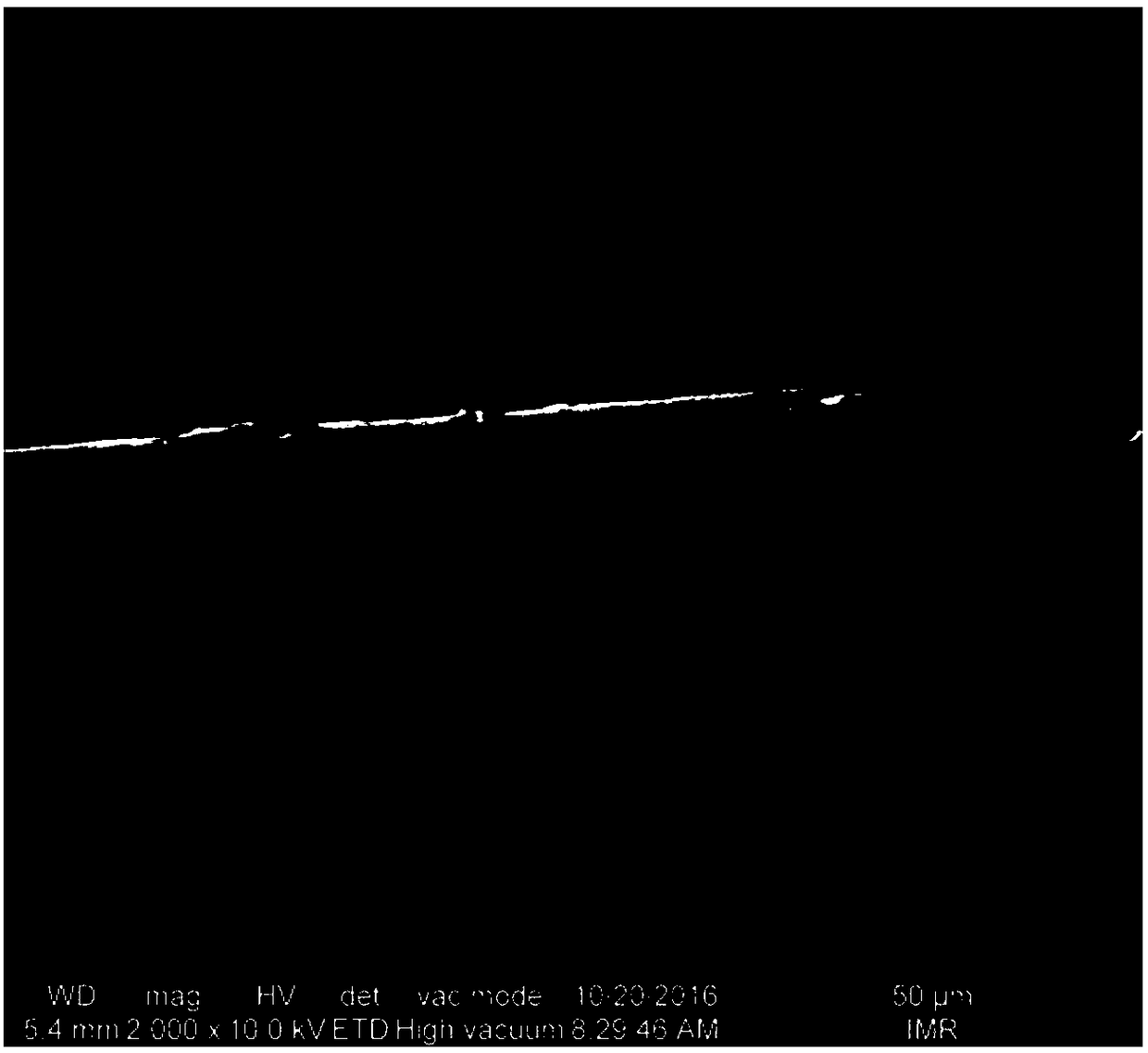

[0048] fiberglass as figure 1 As shown in the arrangement, the fiber is pulled at a speed of 0.3m / s. After dipping and pulling, it is dried at 60°C for 1 hour to obtain a graphene-coated conductive glass fiber. The scanning electron microscope photo is as follows image 3 As shown, the graphene-coated conductive glass fiber prepared by this method has a diameter of about 23.6 μm and a volume conductivity of about 0.11 S / cm.

Embodiment 2

[0050] The difference from Example 1 is that the glass fiber is dipped and pulled 3 times to obtain a graphene-coated conductive glass fiber, and the scanning electron microscope photo is as follows: Figure 4 As shown, the graphene-coated conductive glass fiber prepared by this method has a diameter of about 25.5 μm and a volume conductivity of about 1.5 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com