St/MAH-g-MMA (styrene/maleic anhydride-grafted-methyl methacrylate) graft copolymer, and preparation method and application thereof

A graft copolymer and unsaturated technology, applied in the field of St/MAH-g-MMA graft copolymer and its preparation, achieves the effects of easy control of process conditions, stable alloy performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

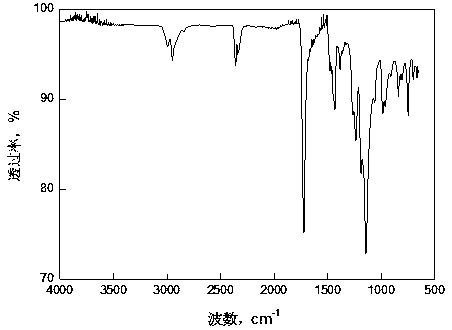

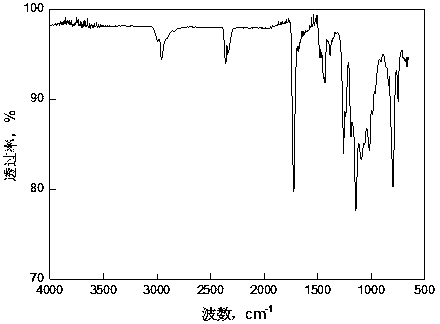

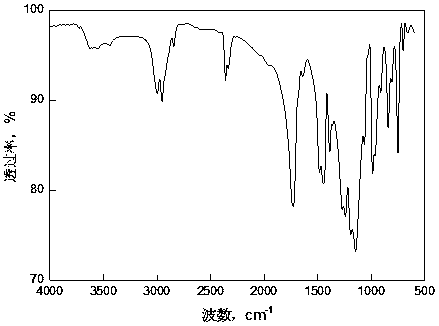

Image

Examples

preparation example Construction

[0036] The present invention also discloses a preparation method of St / MAH-g-MMA graft copolymer, comprising the following steps:

[0037] 1) Add an initiator and RAFT reagent to the methyl methacrylate solution to carry out RAFT active polymerization to obtain polymethyl methacrylate with a thioester group at the end. The initiator, RAFT reagent and methyl methacrylate The molar ratio of feeding is 1:5:200-300, the initiator used in the present invention is AIBN or BPO, also can be azo initiator or organic peroxide initiator, RAFT reagent is dithiobenzoic acid cyanogen One of 2,2'-[methylthiobis(thio)]bis[2-methylpropanoic acid] kind;

[0038] 2) The polymethyl methacrylate obtained in step 1) is reduced by aminolysis to reduce the terminal thioester group to a mercapto group to obtain a polymethyl methacrylate with a mercapto group. The reagent used for the ammonolysis reduction is dimethylphenylphosphine Mixture with n-hexylamine, the feeding molar ratio of dimethylphenyl...

Embodiment 1

[0043] 1) Synthesis of PMMA with a thioester bond at the end:

[0044] The synthesis method is a conventional method, wherein the molar ratio of AIBN: cyanoisopropyl dithiobenzoate: methyl methacrylate is 1:5:200, the solvent is DMF, the reaction temperature is 60°C, and the reaction time is 24h, wherein Methyl methacrylate is 2 mol, and the end is a thioester bond PMMA;

[0045] 2) Synthesis of PMMA with mercapto groups at the end:

[0046] In the above reaction system, add 2 mmol of dimethylphenylphosphine and n-hexylamine respectively (the ratio of dimethylphenylphosphine and n-hexylamine is 1:2), react at room temperature for 1 hour, and obtain PMMA with a mercapto group at the end;

[0047] 3) Synthesis of PMMA macromonomer

[0048] Continue to add 0.05 mol allyl methacrylate in the above reaction system, and react at room temperature for 4h to obtain PMMA macromonomer;

[0049] 4) Synthesis of St / MAH-g-PMMA graft copolymer

[0050]In the above reaction system, 0.05 m...

Embodiment 2

[0053] 1) Synthesis of PMMA with a thioester bond at the end:

[0054] The synthesis method is a conventional method, wherein the molar ratio of AIBN:4-cyano-4-(thiobenzoyl)pentanoic acid:methyl methacrylate is 1:5:200, the solvent is DMF, and the reaction temperature is 60°C , the reaction time is 24h, wherein MMA is 2mol, and the end is thioester bond PMMA;

[0055] 2) Synthesis of PMMA with mercapto groups at the end:

[0056] In the above reaction system, add 5 mmol of dimethylphenylphosphine and n-hexylamine respectively (the ratio of dimethylphenylphosphine and n-hexylamine is 1:2), and react at room temperature for 1 hour to obtain PMMA with a mercapto group at the end;

[0057] 3) Synthesis of PMMA macromonomer

[0058] Continue to add 0.05 mol allyl methacrylate in the above reaction system, and react at room temperature for 4h to obtain PMMA macromonomer;

[0059] 4) Synthesis of St / MAH-g-PMMA graft copolymer

[0060] In the above reaction system, 0.5 mol of styr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com