Polyurethane porous thin film containing grapheme as well as preparation method and application thereof

A porous film and graphene technology, applied in medical science, prosthesis, etc., can solve the problems of increased risk of wound infection, limited drainage capacity, and can not be used for a long time, to prevent external bacterial infection, easy to control performance, good air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

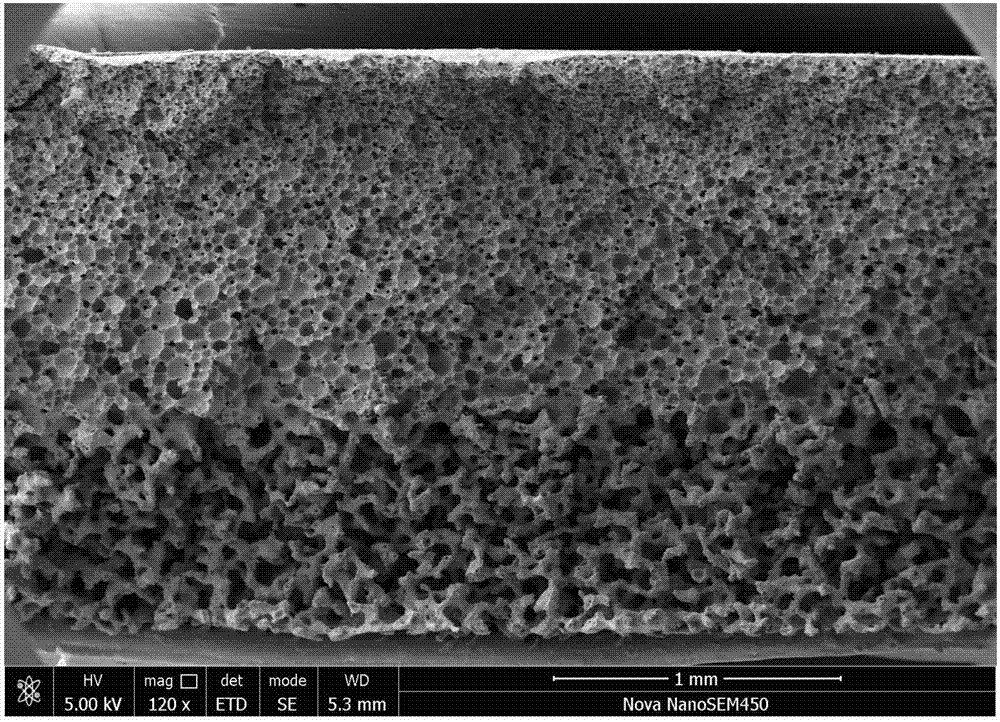

[0040] Dissolve three parts of 25g medical grade polyurethane in 150mL of N,N-dimethylformamide at 60℃, and then add 50mL of graphite oxide to the concentration of 0.25mg / mL, 0.5mg / mL, 2.5mg / mL respectively. The alkene solution was stirred for 2 hours, 60 g of sodium citrate with a particle size of 75-150 μm was added, and the mixture was mechanically stirred for 1 hour. Degas the above solution at room temperature and a vacuum of 0.06 MPa for 20 minutes. Pour the defoamed suspension evenly into a polytetrafluoroethylene mold with a coating film thickness of 2 mm, and then put it in anhydrous ethanol at 25° C. for phase separation and solidify into a film. The cured porous membrane is washed in deionized water at 25°C, and the porogen is fully filtered out. The porous membrane from which the porogen is filtered out is placed in a blast oven at 40°C for drying to obtain a graphene-containing polyurethane porous membrane.

[0041] Structural characterization and performance testi...

Embodiment 2

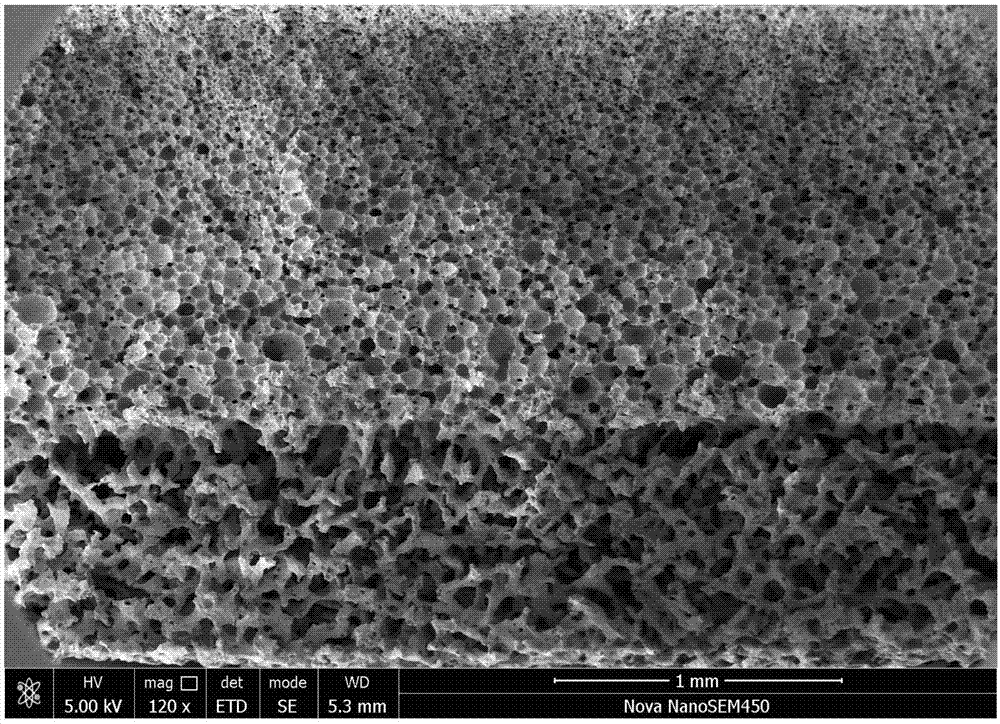

[0055] Dissolve 25g of medical grade polyurethane in 150mL of N,N-dimethylformamide at 60°C, then add 50mL of 0.5mg / mL graphene oxide solution and stir for more than 2h. Degas the above solution at room temperature and a vacuum of 0.06 MPa for 20 minutes. Pour the degassed solution evenly into a polytetrafluoroethylene mold with a coating film thickness of 1 mm, and then put it in anhydrous ethanol at 25°C for phase separation and solidify into a film. The cured polyurethane porous membrane was washed in deionized water at 25°C. The porous film was dried in a 40°C blast oven to obtain a graphene-containing polyurethane porous film.

Embodiment 3

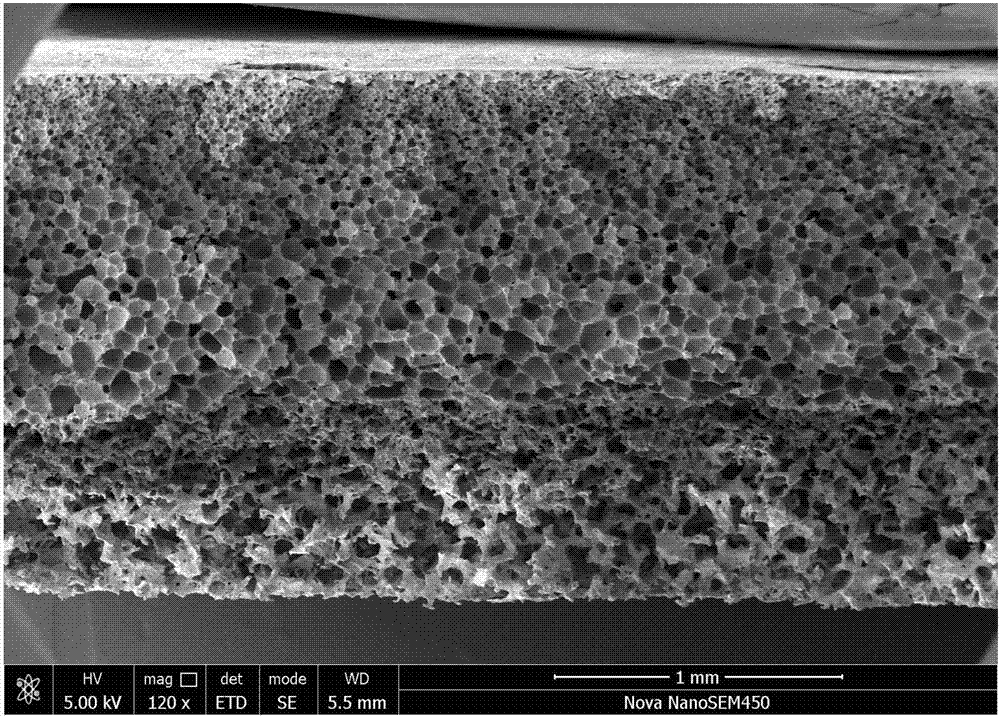

[0057] Dissolve three parts of 25g medical grade polyurethane in 150mL N,N-dimethylformamide at 60℃, and then add 50mL graphene oxide solution with concentration of 5mg / mL, 10mg / mL and 25mg / mL respectively. Stir for 2h, add 60g of sodium citrate with a particle size of 75-150μm, and mechanically stir for 1h. Degas the above solution at room temperature and a vacuum of 0.06 MPa for 20 minutes. Pour the defoamed suspension evenly into a polytetrafluoroethylene mold with a coating film thickness of 2 mm, and then put it in anhydrous ethanol at 25° C. for phase separation and solidify into a film. The cured porous membrane is washed in deionized water at 25°C, and the porogen is fully filtered out. The porous membrane from which the porogen is filtered out is placed in a blast oven at 40°C for drying to obtain a graphene-containing polyurethane porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com