Preparation method of thermoplastic polyurethane porous membrane

A technology of thermoplastic polyurethane and porous film, which is applied in medical science, bandages, absorbent pads, etc. It can solve the problems of limited application range, uneven internal pore structure, film moisture permeability, air permeability and water absorption performance, etc., to achieve hand feeling The effect of comfort, good application prospects, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

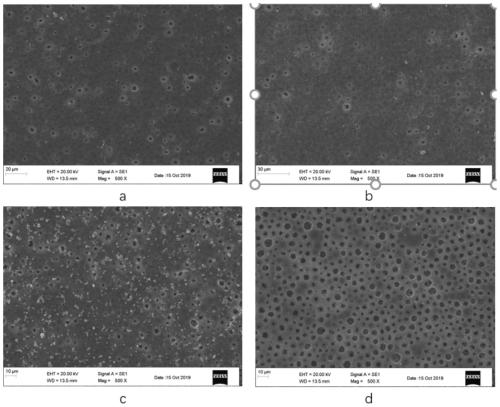

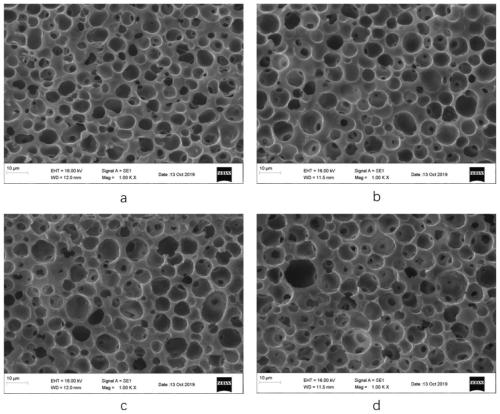

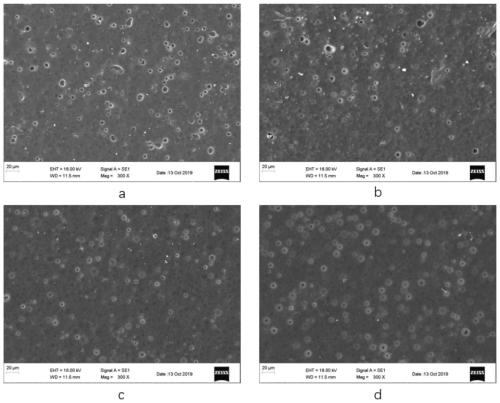

Embodiment 1

[0033] 5g of bio-based thermoplastic polyurethane with a hardness of 85A and 20g of N,N-dimethylformamide were uniformly mixed, dissolved, filtered, and defoamed under heating and stirring at 65°C to obtain a bio-based thermoplastic polyurethane casting solution; Cast on a glass plate, use a scraper to make a 350 μm thick film, and place it in an air humidity environment of 70% for 20 seconds, and put it in an ethanol coagulation bath with a temperature of 25°C, 35°C, 45°C, and 55°C Soak for 20 minutes, take out the film, soak it in deionized water for 1 hour, take it out and bake it at 40°C for 3 hours to obtain a thermoplastic polyurethane porous film. The porosity of the obtained film was 56.4%. As the temperature of the coagulation bath increased, the uniformity of the internal pore structure of the film was improved, and the moisture permeability and mechanical properties were improved. The porosity of the obtained film did not change much, and the average porosity was 56...

Embodiment 2

[0035] 5 g of bio-based thermoplastic polyurethane with a hardness of 85A, 20 g of N,N-dimethylformamide, and 1.25 g of polyethylene glycol (Mn2000) were uniformly mixed, dissolved, filtered, and defoamed at 65°C to obtain bio Base thermoplastic polyurethane film casting solution; cast it on a glass plate, scrape it with a scraper to make a 350μm thick film, and place it in an air humidity environment of 70% for 20s, and put it in the temperature of 25°C, 35°C, 45°C ℃, 55℃ ethanol coagulation bath for 20min, take out the membrane, soak it in deionized water for 1h, take it out and bake it at 40℃ for 3h to get a thermoplastic polyurethane porous film. With the increase of coagulation bath temperature, the surface hole density of the film , The uniformity of the internal pore structure is improved, and the moisture permeability and mechanical properties are improved. The porosity of the obtained film did not change much with temperature, and the average porosity was 66.2%. When ...

Embodiment 3

[0037] 5 g of bio-based thermoplastic polyurethane with a hardness of 85A, 20 g of N,N-dimethylformamide, and 3.125 g of polyethylene glycol (Mn2000) were uniformly mixed, dissolved, filtered, and defoamed at 65°C to obtain bio Base thermoplastic polyurethane film casting solution; cast it on a glass plate, scrape it with a scraper to make a 350μm thick film, and place it in an air humidity environment of 70% for 20s, and put it in the temperature of 25°C, 35°C, 45°C ℃, 55℃ ethanol coagulation bath for 20min, take out the membrane, soak it in deionized water for 1h, take it out and bake it at 40℃ for 3h to get a thermoplastic polyurethane porous film. With the increase of coagulation bath temperature, the surface hole density of the film , The uniformity of the internal pore structure is improved, and the moisture permeability and mechanical properties are improved. The porosity of the film obtained varies little with the temperature of the coagulation bath, and the average po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com