Self-supporting porous carbon used for supercapacitor electrode material and preparing method thereof

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of cumbersome preparation process, difficult control of product performance, inability to use supercapacitor electrodes, etc., and achieve the effect of reducing production costs and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

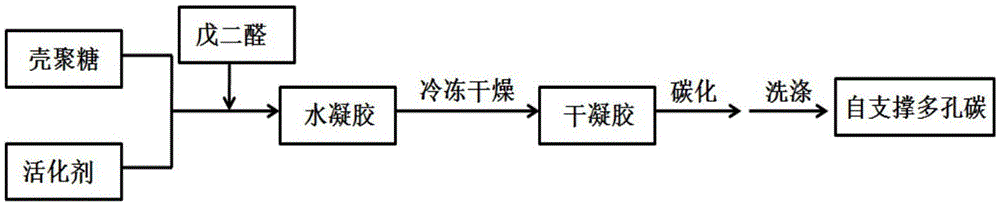

Method used

Image

Examples

Embodiment 1

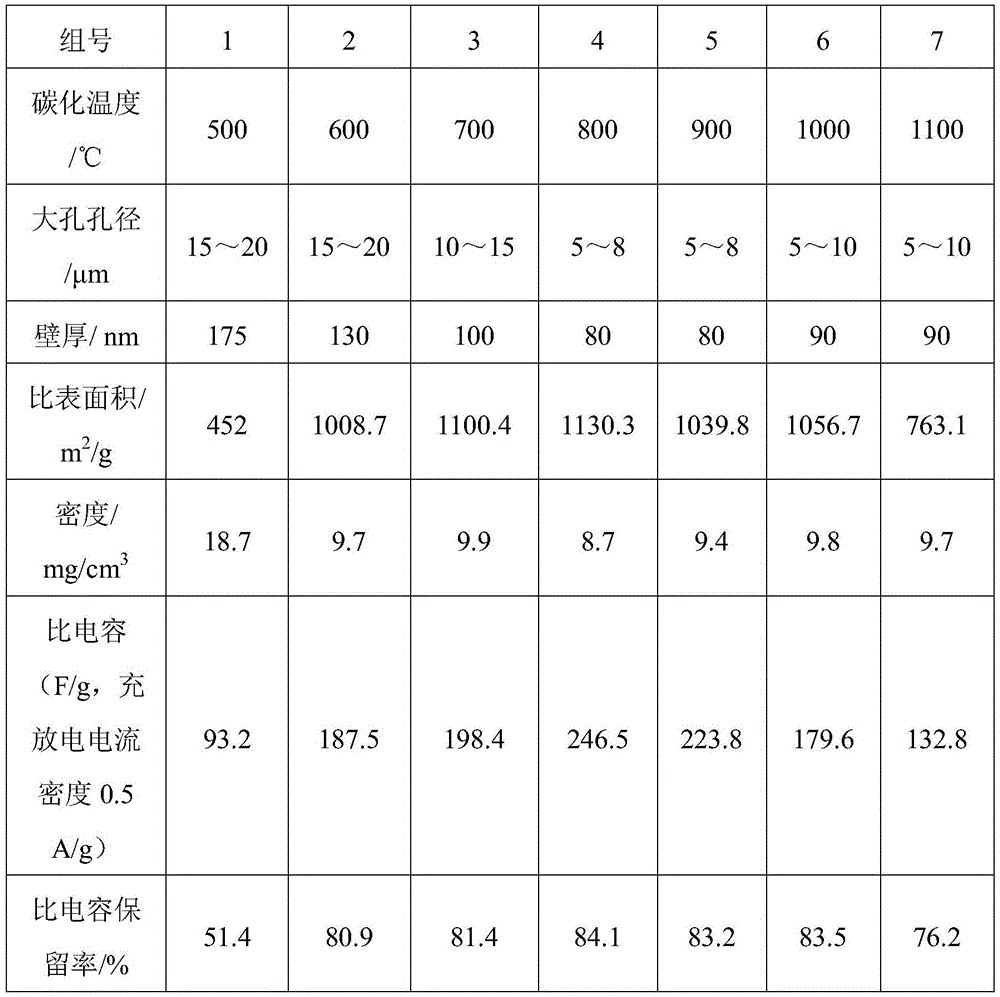

[0020] (1) Preparation of chitosan gel: Dissolve chitosan in dilute acetic acid solution to prepare a 1.0wt% solution, take 20g of chitosan solution, add 0.12gKOH under stirring, then slowly add 120μL of 50% pentano Dialdehyde aqueous solution, wherein the mass ratio of chitosan, activator, glutaraldehyde and water is 1:0.6:0.3:100, mixed evenly and left at room temperature, the solution gradually turns into a gel.

[0021] (2) Preparation of self-supporting porous carbon: freeze-dry the prepared chitosan hydrogel to obtain xerogel mixed with KOH, put the xerogel in a tube furnace, and carbonize it at 900°C for 2h under nitrogen, and use Wash the carbonized product with 0.5mol / L dilute hydrochloric acid and water to remove soluble impurities, and finally dry it in a 100°C drying oven to obtain a self-supporting porous carbon material.

[0022] The prepared self-supporting porous carbon material has a macropore diameter of 8-12 μm, a wall thickness of about 180 nm, and a mesopo...

Embodiment 2

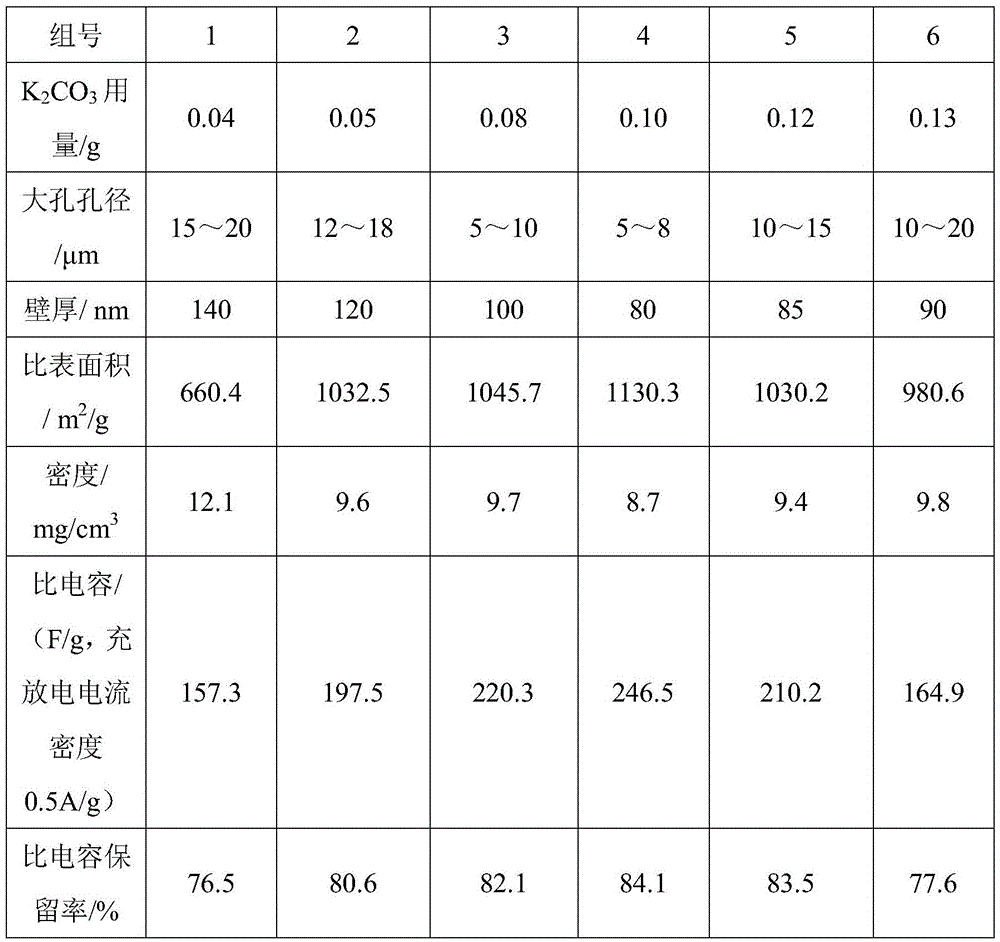

[0024] (1) Preparation of chitosan gel: Dissolve chitosan in dilute acetic acid solution, prepare 1.0wt% solution, get 20g chitosan solution, add 0.10g K 2 CO 3 , and then slowly add 120 μL of 50% glutaraldehyde aqueous solution, wherein the mass ratio of chitosan, activator, glutaraldehyde and water is 1:0.5:0.3:100, mix well and stand at room temperature, the solution gradually becomes coagulated glue;

[0025] (2) Preparation of self-supporting porous carbon: freeze-dry the prepared chitosan hydrogel to obtain 2 CO 3 Put the dry gel into a tube furnace, carbonize it at 800°C for 2h under nitrogen, wash the carbonized product with 0.5mol / L dilute hydrochloric acid and water to remove soluble impurities, and finally dry it in a drying oven at 100°C. A self-supporting porous carbon material is obtained.

[0026] The prepared self-supporting porous carbon material has a macropore diameter of 5-8 μm, a wall thickness of 80 nm, and a mesopore and micropore structure on the po...

Embodiment 3

[0028] (1) Preparation of chitosan hydrogel: dissolve chitosan in dilute acetic acid solution, prepare 1.0wt% solution, get 20g chitosan solution, add 0.08gNa 2 CO3 , and then slowly add 120 μL of 50% glutaraldehyde aqueous solution, wherein the mass ratio of chitosan, activator, glutaraldehyde and water is 1:0.4:0.3:100, mix well and stand at room temperature, the solution gradually becomes coagulated glue;

[0029] (2) Preparation of self-supporting porous carbon: freeze-dry the prepared chitosan hydrogel to obtain 2 CO 3 Put the dry gel into a tube furnace, carbonize it at 900°C for 2h under nitrogen, wash the carbonized product with 0.5mol / L dilute hydrochloric acid and water to remove soluble impurities, and finally dry it in a drying oven at 100°C. A self-supporting porous carbon material is obtained.

[0030] The prepared self-supporting porous carbon material has a macropore diameter of 9-13 μm, a wall thickness of 200 nm, and a specific surface area of 1026.4 m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com