Laser solid forming method for high-entropy alloy member

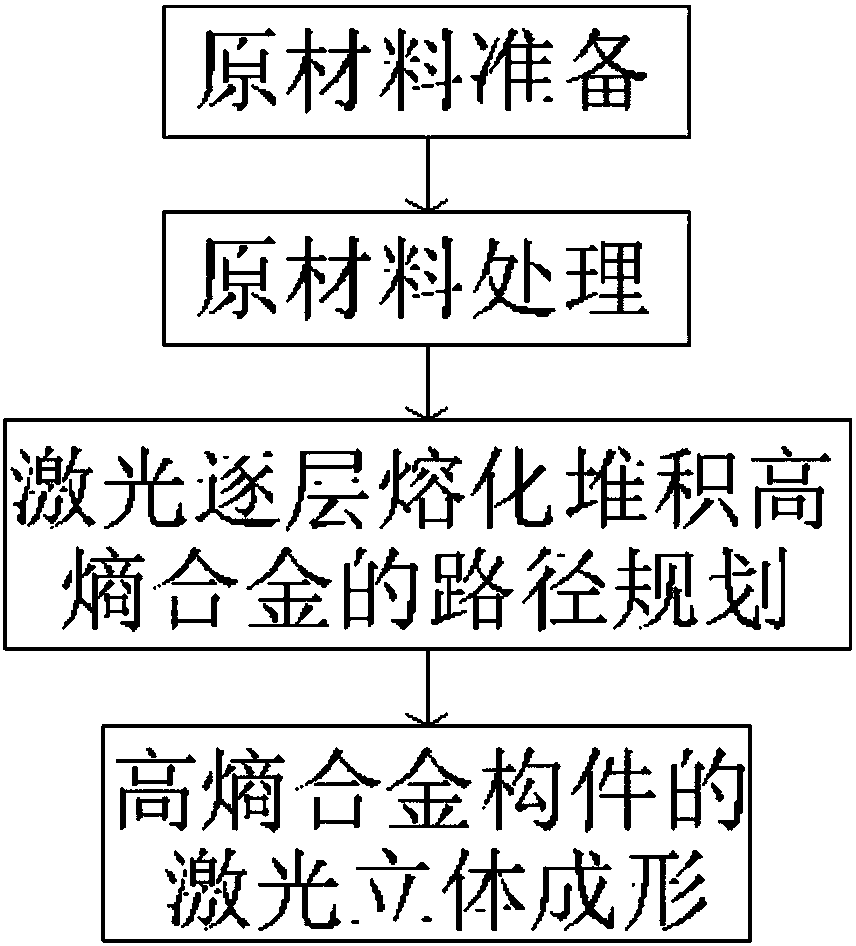

A laser three-dimensional forming, high-entropy alloy technology, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve the problem of component segregation, reduce the performance of alloy components, restrict the application of high-entropy alloy components, poor machining and manufacturing performance, etc. problems, to achieve the effects of controllable performance, improved material utilization, and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] In this example, a high-entropy alloy round tube is prepared by a laser three-dimensional forming preparation method. The test piece belongs to a thin-walled rotating piece, and the process includes the following steps:

[0042] (1) Raw material preparation: FeCoNiMnCr spherical alloy powder with an average particle size of 100 μm, stainless steel base material;

[0043] (2) Raw material treatment: The FeCoNiMnCr spherical alloy powder was dried in a vacuum oven at 100 °C for 2 hours and then cooled naturally, and then loaded into the barrel of the powder feeder after cooling; Immerse the polished substrate in acetone in the beaker, and then place it in an ultrasonic cleaning apparatus for cleaning, and then repeat the polishing, immersion, and cleaning steps at least once, then dry the cleaned substrate, and then place into the forming chamber protected by inert gas, and fixedly clamped on the turntable for use.

[0044] (3) Determine the basic process parameters of h...

example 2

[0051] In this example, the high-entropy alloy blade is prepared by the laser three-dimensional forming preparation method. The process is the same as that of Example 1. The powder and laser additive manufacturing process is the same. The difference lies in the path planning and code generation: the three-dimensional model of the blade is divided into Layer slices, each layer can be stacked by a single linear scan, but the scanning direction of each layer is tilted at a certain angle around the C-axis of the turntable. image 3 The actual picture of the experimental piece of the blade prepared by the method of this example is shown.

[0052] Using the method of this example, three kinds of process parameters as shown in the following table 1 were selected to manufacture high-entropy alloy blades respectively, and the high-entropy alloy blades manufactured under different process conditions were analyzed by optical microscope, and the following results were obtained: Figure 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com