Preparation method of silicon-based negative electrode binder of lithium battery and binder

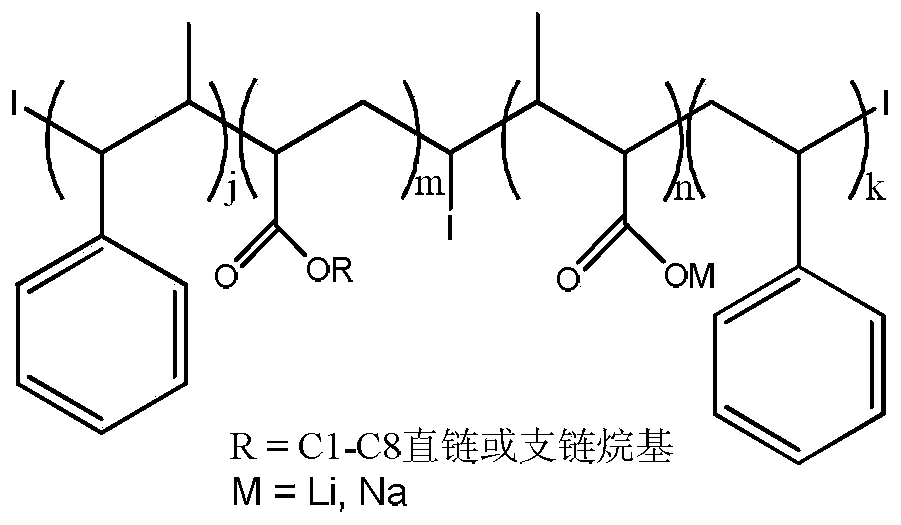

A silicon-based negative electrode and binder technology, which is applied in battery electrodes, lithium batteries, conductive adhesives, etc., can solve the problems of less research on lithium battery binders, and achieve excellent electrochemical performance, low internal resistance, performance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 5L stainless steel polymerization reactor, add 2000mL deionized water, 18.0g n-hexadecane, 100.0g (meth)butyl acrylate, 6.0g sodium lauryl sulfate, 16g CHI 3 , 5.0g of potassium persulfate, cooled to 0°C, passed through high-purity nitrogen to exhaust oxygen until the oxygen content is lower than 5ppm, stirred at a high speed at 0°C for 30 minutes to obtain a fine emulsion; raised the temperature to 35°C for polymerization reaction for 3 hours, and obtained active polybutylacrylate seed emulsion;

[0027] Add 200g of styrene into the kettle, stir and disperse at room temperature, swell for 2h, raise the temperature to 45°C and continue the reaction for 5h, then stop;

[0028] Add 20g of 50wt% NaOH solution, stir and hydrolyze at 65°C for 5h, and adjust the pH to 7.0 with 1mol / L hydrochloric acid to obtain polyethylene-polybutylacrylate-polyacrylic acid-polystyrene block copolymer binder.

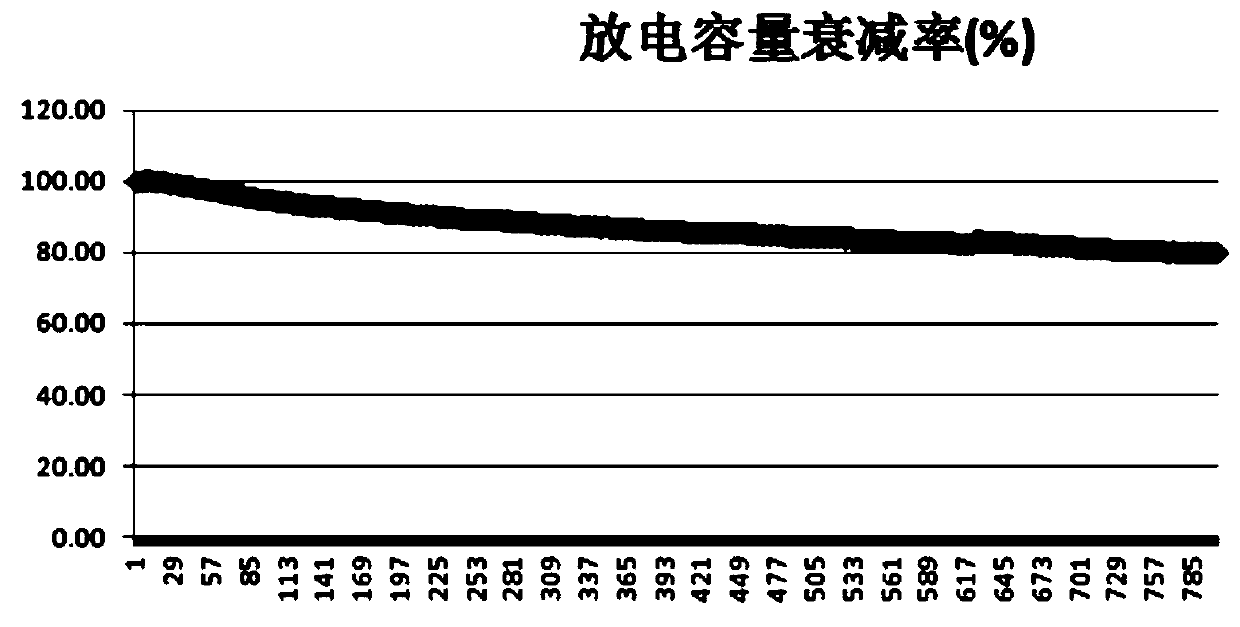

[0029] After diluting the aqueous solution of the above block copolymer bin...

Embodiment 2

[0032] In a 5L stainless steel polymerization reactor, add 2000mL deionized water, 18.0g n-hexadecane, 200.0g butyl methacrylate, 12.0g sodium lauryl sulfate, 50g CHI 3 , 8.0g potassium persulfate, cooled to 1°C, passed through high-purity nitrogen to exhaust oxygen until the oxygen content is lower than 5ppm, stirred at a high speed at 1°C for 30min to obtain a fine emulsion; raised the temperature to 35°C and polymerized for 2h to obtain active polybutylmethacrylate Ester seed emulsion;

[0033] Add 300g of styrene into the kettle, stir and disperse at room temperature, swell for 2.5h, raise the temperature to 45°C and continue the reaction for 6h, then stop;

[0034] Add 50g of 50wt% NaOH solution, stir and hydrolyze at 60°C for 5h, adjust the pH to 7.0 with 1mol / L hydrochloric acid, and obtain polyethylene-polybutylmethacrylate-polymethacrylic acid-polystyrene block copolymer binder .

[0035]After diluting the aqueous solution of the block copolymer binder to adjust the...

Embodiment 3

[0037] In a 5L stainless steel polymerization reactor, add 2000mL deionized water, 14.0g n-hexadecyl alcohol, 150.0g (meth)methyl acrylate, 10.0g cetyltrimethylammonium bromide, 45g IC 4 f 8 1, 10.0g azobiscyanovaleric acid, cooled to 2°C, feed high-purity nitrogen gas to exhaust oxygen until the oxygen content is lower than 5ppm, stir at a high speed at 2°C for 30min to obtain a fine emulsion; heat up to 35°C for polymerization for 2.5h, and obtain Active polymethyl acrylate seed emulsion;

[0038] Add 600g of styrene into the kettle, stir and disperse at room temperature, swell for 3.0h, raise the temperature to 40°C and continue the reaction for 6h, then stop;

[0039] Add 30g of 50wt% NaOH solution, stir and hydrolyze at 65°C for 5h, and adjust the pH to 7.0 with 1mol / L hydrochloric acid to obtain polyethylene-polymethylacrylate-polyacrylic acid-polystyrene block copolymer binder.

[0040] After diluting the aqueous solution of the above block copolymer binder to adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com