Preparation method for molecular sieve/organic composite permeable vaporization membrane

A technology of pervaporation membrane and molecular sieve, which is applied in the field of membrane separation, can solve the problems of easy formation of defects in the phase interface, poor permeation separation performance, complicated preparation process, etc., and achieves good membrane surface continuity, increased filling area, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of nano-scale Silicatile-1 molecular sieve: Sodium hydroxide, tetraethylorthosilicate (TEOS), tetrapropylammonium hydroxide (TPAOH) and water were mixed in molar ratio n (NaOH) : n (TEOS) : n (TPAOH) : n (H 2 O) = 1: 50 : 18 : 1000 to prepare molecular sieve synthesis liquid, stir magnetically at room temperature, age for 40 h, crystallize in a reaction kettle at 100 ° C for 60 h, take it out and cool it, centrifuge, wash with deionized water until neutral and dried, and calcined at 550 °C for 6 h to obtain nano-scale Silicatile-1 molecular sieves.

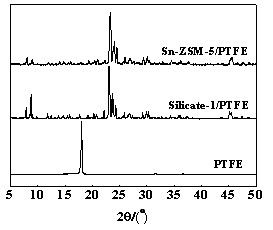

[0028] Using ethanol as a solvent, Silicatile-1 molecular sieve was prepared into a suspension with a mass fraction of 10% by ultrasonic oscillation. The ultrasonic power was 100W, and the oscillation was 20 minutes. The film was coated on the PTFE membrane by spraying method. The PTFE membrane had a pore size of 0.05 μm and dried at room temperature. , to obtain a Silicatile-1 / PTFE molecular sieve base fil...

Embodiment 2

[0033] Carry out the synthesis of Ge-ZSM-5 / PTFE composite membrane according to the step of Example 1, the difference is that the metal salt doped in the molecular sieve synthesis liquid is germanium ethylate, the PTFE membrane aperture is 0.05 μ m, and the Silicatile-1 molecular sieve suspension mass concentration is 5 %, Ge-ZSM-5 molecular sieve was prepared into a suspension with a mass fraction of 5%, the thickness of the bottom membrane of the molecular sieve was 10 μm, and the thickness of the separation layer was 10 μm. The obtained Ge-ZSM-5 / PTFE spiral-wound composite membrane was used in acetone / water pervaporation separation, the results are shown in Table 1.

Embodiment 3

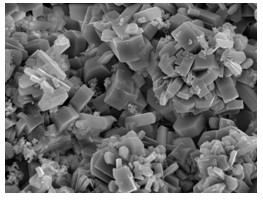

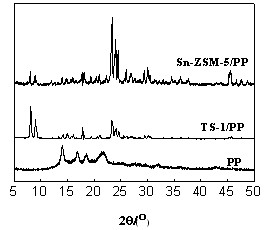

[0035] Carry out the synthesis of Sn-ZSM-5 / PP composite membrane according to the step of example 1, difference is that molecular sieve base film adopts TS-1 molecular sieve, and the mass concentration of TS-1 molecular sieve suspension is 15%, and Sn-ZSM-5 molecular sieve is formulated into The suspension with a mass fraction of 15%, the pore size of the PP membrane is 0.5 μm, the thickness of the molecular sieve bottom membrane is 5 μm, and the thickness of the separation layer is 25 μm. The X-ray diffraction and scanning electron microscopy of the prepared Sn-ZSM-5 / PP composite membrane are respectively See image 3 and Figure 4 , Sn-ZSM-5 / PP spiral-wound composite membrane was used for the pervaporation separation of methanol / water. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com