Heavy metal repairing material based on organic sludge and use method of material

A repair material and organic sludge technology, applied in the direction of organic fertilizer, restoration of polluted soil, soil conditioning materials, etc., can solve the problems of high cost, failure to achieve volume reduction and resource utilization, increase in dry matter, and achieve increase Soil cation exchange capacity, widening the field of resource utilization, and reducing the effect of bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

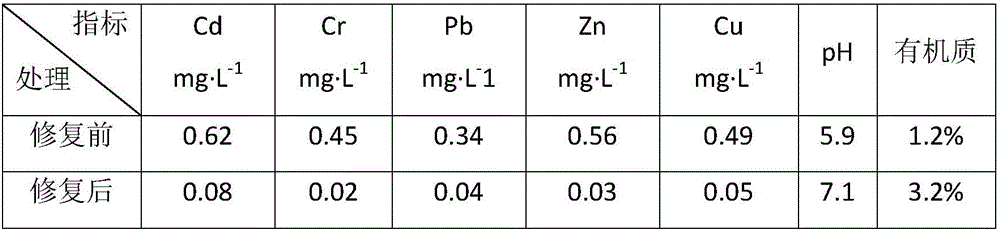

Embodiment 1

[0030] A heavy metal restoration material based on organic sludge, prepared from raw materials with the following mass fractions:

[0031] Organic treatment sludge 40%

[0032] Mineral material 45%

[0033] Compound stabilizer 15%.

[0034] The organic treatment sludge is prepared by the following process: 1) the municipal domestic sludge is treated with an aerobic digestion process, and then dehydrated by pressure filtration to obtain a filter cake with a water content of 60%; 2) The filter cake is composted, fermented at 45°C for 5 days, then transferred to the ripening room for ripening, sterilization and deworming eggs, and ripened for 10 days; 3) After the ripening is completed, it is further dried and dehydrated until the moisture content reaches 20%, and organic treatment is obtained sludge.

[0035] The mineral material is composed of limestone, slag and zeolite, wherein the mass ratio of limestone, slag and zeolite is 1:7:2.

[0036] The compound stabilizer is com...

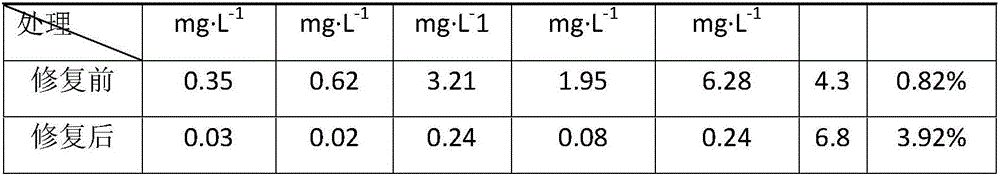

Embodiment 2

[0050] A heavy metal restoration material based on organic sludge, prepared from raw materials with the following mass fractions:

[0051] Organic treatment sludge 65%

[0052] Mineral material 30%

[0053] Compound stabilizer 5%.

[0054] The organic treatment sludge is prepared by the following process: 1) the municipal domestic sludge is treated with an aerobic digestion process, and then dehydrated by pressure filtration to obtain a filter cake with a moisture content of 55%; 2) The filter cake is composted, fermented at 35°C for 8 days, then transferred to the ripening room for ripening, sterilization and deworming eggs, and ripened for 15 days; 3) After the ripening is completed, it is further dried and dehydrated until the moisture content reaches 10%, and organic treatment is obtained sludge.

[0055] The mineral material is composed of limestone, slag and sepiolite, wherein the mass ratio of limestone, slag and sepiolite is 2:7:1.

[0056] The compound stabilizer ...

Embodiment 3

[0069] A heavy metal restoration material based on organic sludge, prepared from raw materials with the following mass fractions:

[0070] Organic treatment sludge 85%

[0071] Mineral material 14%

[0072] Compound stabilizer 1%.

[0073] The organic treatment sludge is prepared by the following process: 1) the municipal domestic sludge is treated with an aerobic digestion process, and then dehydrated by pressure filtration to obtain a filter cake with a water content of 45%; 2) The filter cake is composted, fermented at 45°C for 10 days, then transferred to the aging room for aging, sterilization and deworming eggs, and aging for 10 days; 3) After the aging is completed, it is further dried and dehydrated to a moisture content of 20% to obtain organic treatment sludge.

[0074] The mineral material is composed of limestone, slag and zeolite, wherein the mass ratio of limestone, slag and zeolite is 2:5:3.

[0075] The compound stabilizer is composed of calcium hydroxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com