Super capacitor battery and manufacturing method thereof

A technology of supercapacitor batteries and supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double-layer capacitors. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

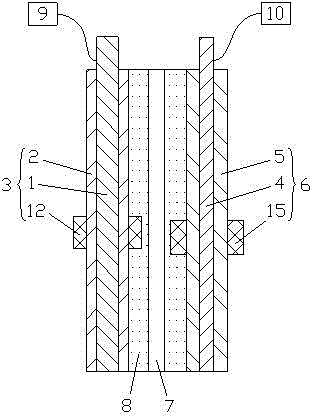

[0036] (1) Preparation of positive electrode sheet 3: Cover at least one positive electrode active layer containing positive electrode active material on the surface of positive electrode current collector 1 to make positive electrode sheet 3;

[0037] (2) Connection of the positive electrode 3: connect the positive electrode current collector 1 of the positive electrode sheet 3 to the positive electrode 9;

[0038] (3) Preparation of the negative electrode sheet 6: covering at least one negative electrode active layer containing the negative electrode active material on the surface of the negative electrode current collector 4 to make the negative electrode sheet 6;

[0039] (4) Connection of the negative electrode 10: connect the negative electrode current collector 4 of the negative electrode sheet 6 to the negative electrode 10;

[0040] (5) Encapsulation: a separator 7 is arranged between the positive electrode 3 and the negative electrode 6, and an electrolyte 8 is added...

Embodiment 1

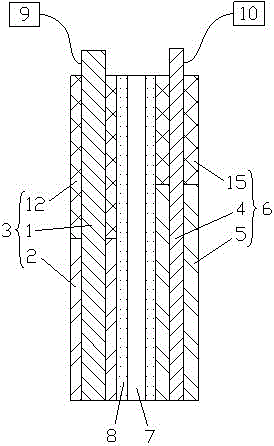

[0044] Example 1: Such as figure 1 As shown, the positive electrode current collector 1 is aluminum foil, the surface of the positive electrode current collector 1 is covered with the first positive electrode active layer 2 containing activated carbon, the surface of the positive electrode current collector 1 is also covered with the second positive electrode active layer 12 containing cobalt acid, and the first positive electrode active layer 2 and the second positive electrode active layer 12 and do not cover different regions provided on the surface of the same positive electrode current collector 1 to make a positive electrode sheet 3 . The negative electrode current collector 4 is copper foil, the surface of the negative electrode current collector 4 covers the first negative electrode active layer 5 comprising activated carbon, the surface of the negative electrode current collector 4 also covers the second negative electrode active layer 15 comprising graphite, the fir...

Embodiment 2

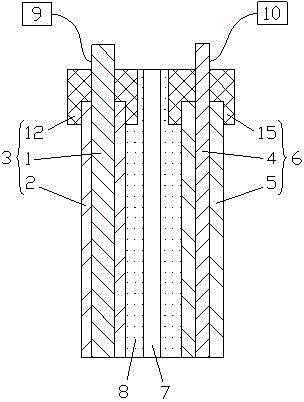

[0045] Example 2: Such as figure 2 As shown, the positive electrode current collector 1 is aluminum foil, the surface of the positive electrode current collector 1 is covered with the first positive electrode active layer 2 containing activated carbon, the surface of the positive electrode current collector 1 is also covered with the second positive electrode active layer 12 containing cobalt acid, and the first positive electrode active layer 2 and the second positive electrode active layer 12 are arranged side by side and partially overlapped on the surface of the same positive electrode current collector 1 to make a positive electrode sheet 3 . The negative electrode current collector 4 is copper foil, the surface of the negative electrode current collector 4 covers the first negative electrode active layer 5 comprising activated carbon, the surface of the negative electrode current collector 4 also covers the second negative electrode active layer 15 comprising graphite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com