Sublimation ink-jetting ink used for industrial nozzle and manufacturing method thereof

An inkjet ink, thermal sublimation technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of affecting production efficiency, high cost, high price, etc., to achieve less dye residue, short transfer time, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

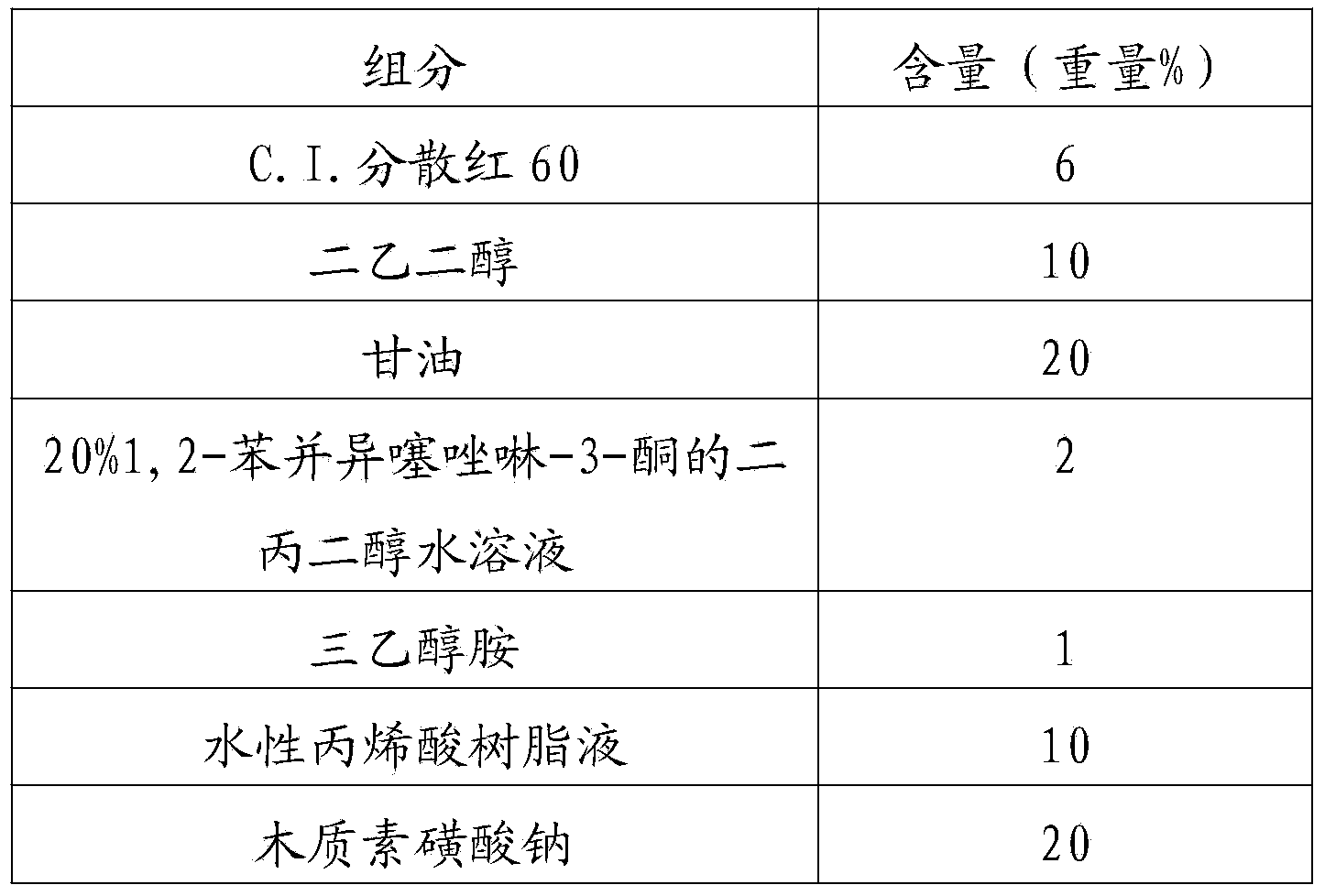

[0041] Dye Sublimation Inkjet Ink(Red) for Industrial Printheads

[0042] formula:

[0043]

[0044]

[0045] Preparation:

[0046] (1) Preparation of color paste: Take C.I. Disperse Red 60, SurfynolMD-20 (Shanghai Sangjing Chemical Co., Ltd.) and sodium lignosulfonate in the above ratio, and then take 50% of the amount of diethylene glycol, 1% Surfynol- Mix 50% of 104e (Shenzhen Xinzhihe Chemical Raw Materials Co., Ltd.) and 40% of ultra-pure water at room temperature, mix well, and grind in a sand mill for 28 hours. Measure the particle size of the ground mixture. Its average particle size d50 is less than 90nm, d90 is less than 150nm, and red color paste is obtained;

[0047] (2) Preparation of the finished product: take 20% of the above ratio of 1,2-benzisothiazolin-3-one in dipropylene glycol aqueous solution, triethanolamine, glycerin, water-based acrylic resin solution, BYK-380N (Byk Chemicals (Tongling ) Co., Ltd.) and EDTA-4Na, and then take 50% of the above-...

Embodiment 2

[0049] Dye Sublimation Inkjet Ink for Industrial Printheads (Blue)

[0050] formula:

[0051] components

Content (weight%)

C.I. Disperse Blue 72

5

20

10

5-Chloro-2-methyl-4-isothiazolin-3-one

0.1

tris hydroxymethyl amino methane

0.5

Waterborne Polyurethane Resin Liquid

3

BYK-190

40

[0052] EFKA-4560

0.6

ET-115

0.7

Surfynol DF-75

0.1

EDTA-2Na

1

Ultra-pure water

19

[0053] Preparation:

[0054] (1) Preparation of color paste: Take C.I. Disperse Blue 72, SurfynolDF-75 (Guangzhou Liangu Fine Chemical Co., Ltd.) and BYK-190 (Byk Chemical (Tongling) Co., Ltd.) in the above ratio, and then take triethylene glycol 30% of the dosage, 60% of the dosage of ET-115 and 60% of the dosage of ultra-pure water, mixed at room temperature, stirred evenly and then ground in a sand mill for 28 hours, measur...

Embodiment 3

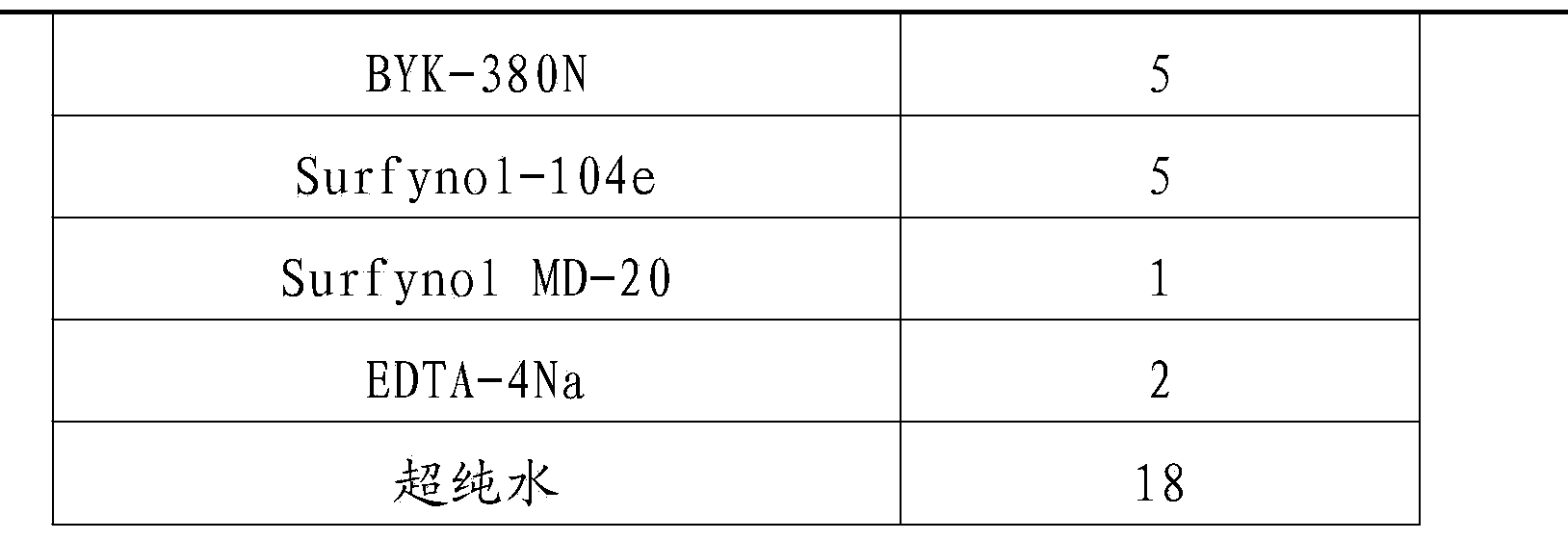

[0057] Dye Sublimation Inkjet Ink (Yellow) for Industrial Printheads

[0058] formula:

[0059] components

Content (weight%)

C.I. Disperse Yellow 54

3

Polyethylene glycol 600

30

15

5-Chloro-2-methyl-4-isothiazolin-3-one

1

0.2

Modified binary vinyl chloride resin solution

5

Ethylene bis stearic acid amide

30

[0060] BYK-333

3

Surfynol CT-221

2

EnviroGem AD-01

0.3

EDTA

0.5

Ultra-pure water

10

[0061] Preparation:

[0062] (1) Preparation of color paste: Take C.I. Disperse Yellow 54, EnviroGemAD-01 (Dongzhifeng Import and Export (Shenzhen) Co., Ltd.) 40% of the amount of ethylene glycol 600, 70% of the amount of SurfynolCT-221 (Shenzhen Xinzhihe Chemical Raw Materials Co., Ltd.) and 40% of the amount of ultrapure water, mixed at room temperature, stirred evenly, and ground in a sand mill for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com