Disperse dye composition and disperse dyes

A technology of disperse dyes and compositions, applied in the directions of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems that application properties such as lifting force and color fastness cannot fully meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

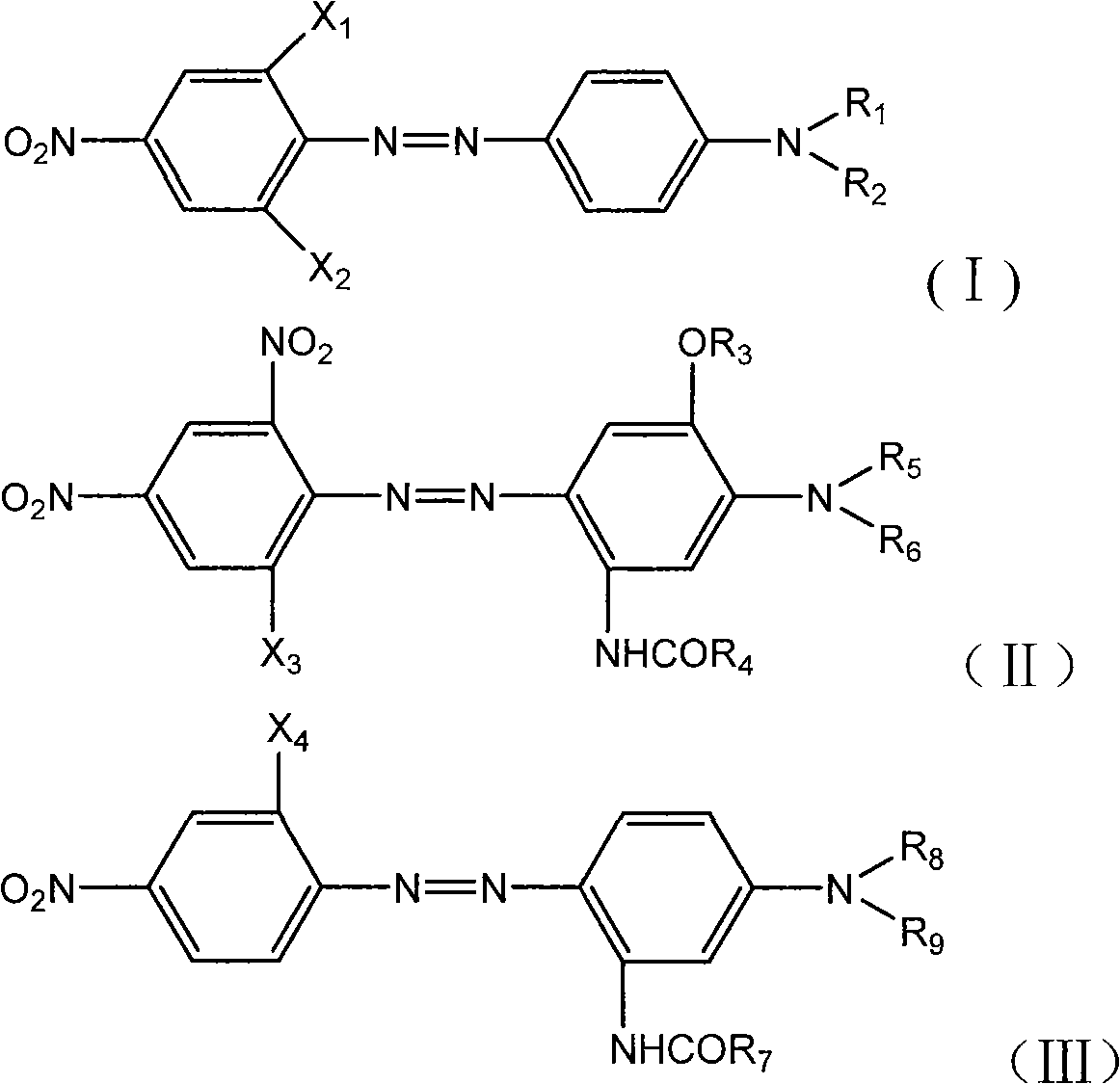

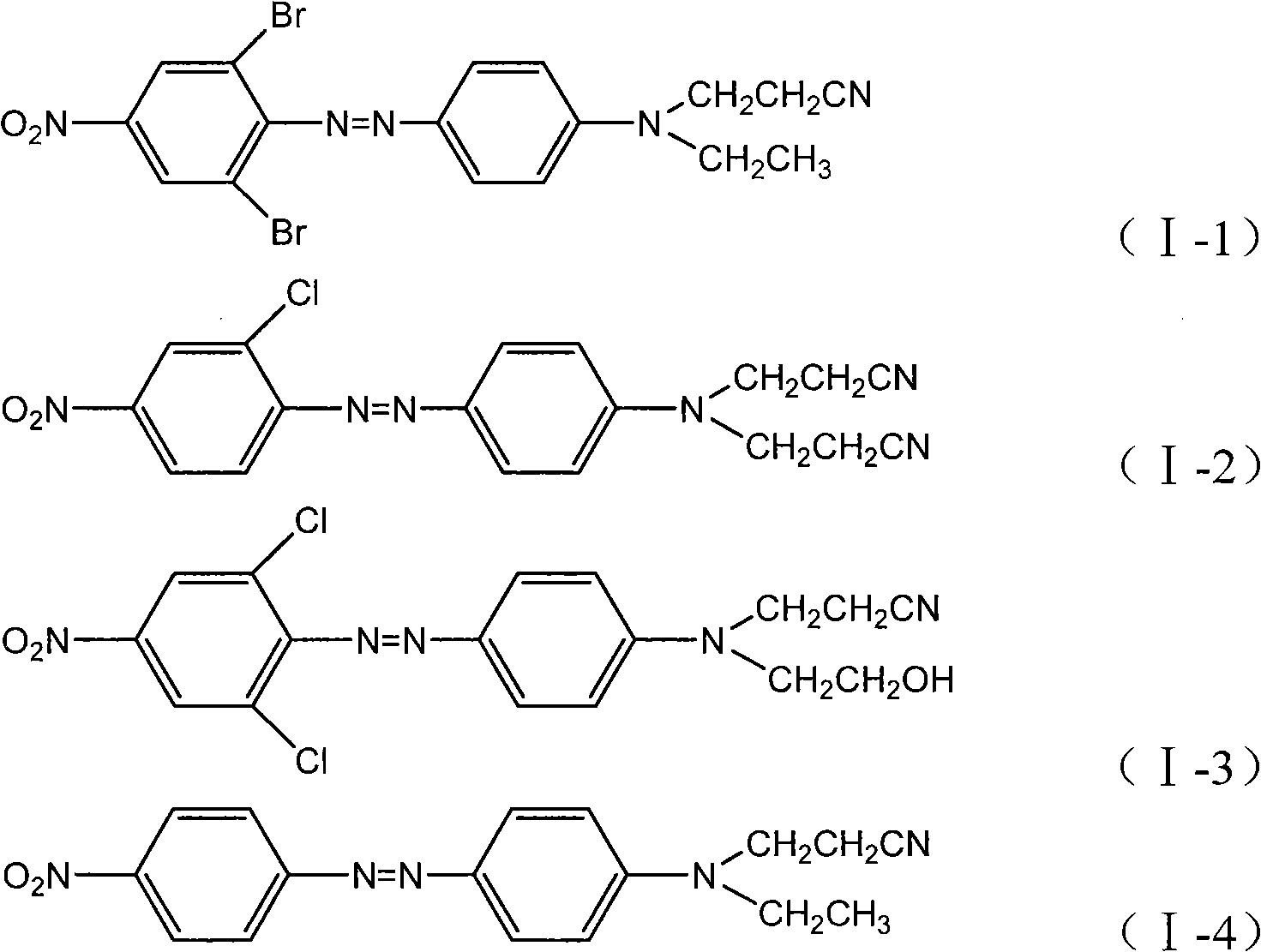

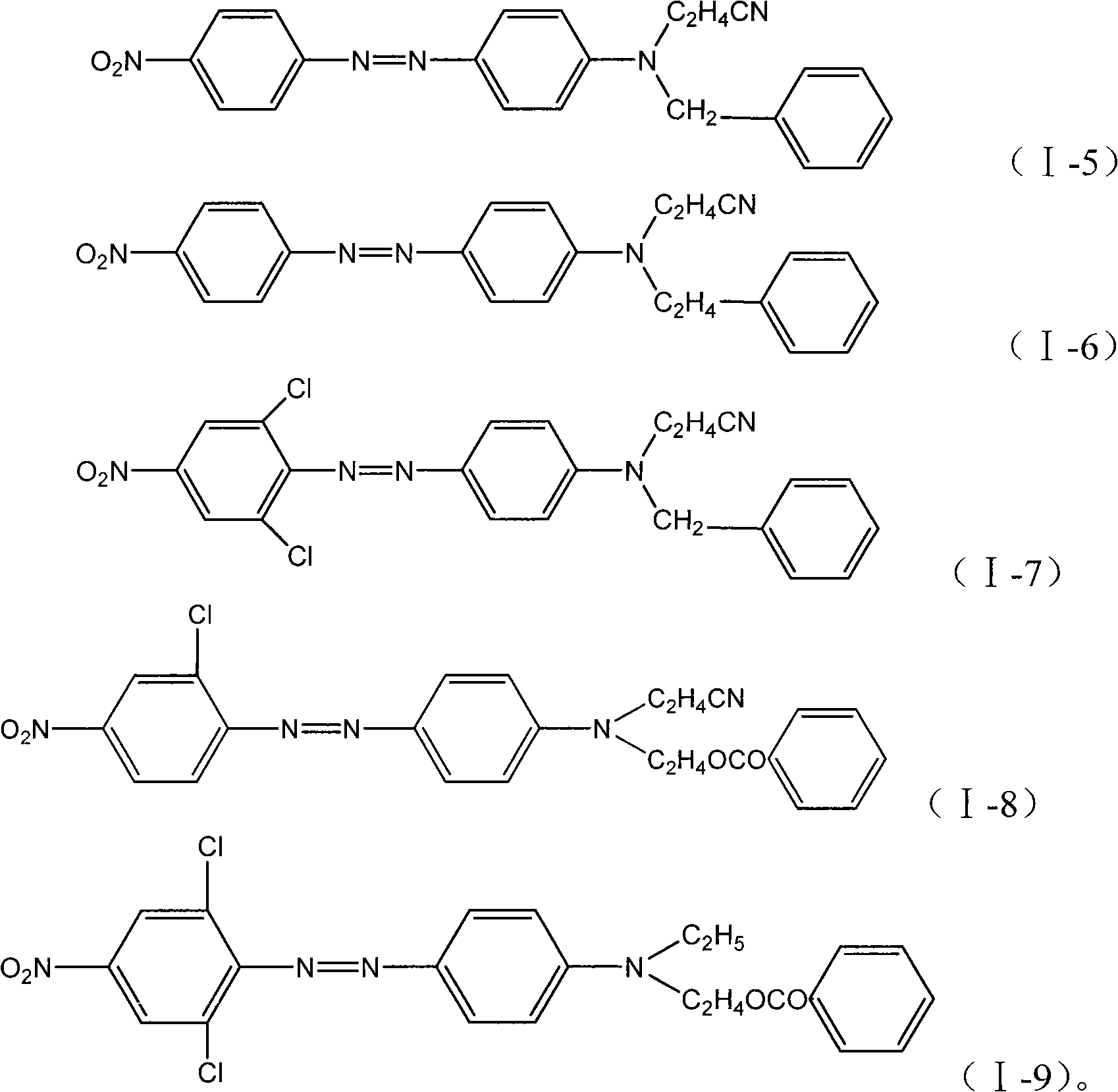

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Be the component A of 15 gram formula (I-1), the component A of 20 gram formula (I-5), the component B of 56 gram formula (II-1), 9 gram formula (III-1) Component C, 128 grams of sodium lignosulfonate, after adding 600 ml of water to blend, grind and disperse with a grinder, and spray dry to obtain the powdered disperse dye product.

[0042]

[0043] Above-mentioned dye product can be dyed according to conventional method, for example, get 0.5 gram of above-mentioned powdery dye product, disperse in 500 milliliters of water, absorb 20 milliliters and mix with 60 milliliters of water, be 5 with acetic acid dyeing bath pH, be warmed up to Put 2 grams of polyester textile material at 70°C at the same time for dyeing, heat up from 70°C to 130°C within 30 minutes, keep warm for 30 minutes, and start sampling when it cools to 90°C, then wash, rinse and dry to get bright colors For dyed fabrics with a navy blue hue, the national standards GB / T3921-1997, GB / T3920-1997, GB / ...

Embodiment 2~20

[0045] According to the dye preparation method and dyeing method described in Example 1, the difference is that the dye components and proportions shown in the following table 1 are used to obtain a navy blue to black color with excellent dyeing fastness and full hue. Dyed fabric.

[0046] Table 1

[0047]

[0048]

Embodiment 21

[0050]The quality is 13 grams of component A of formula (I-1), the component A of 20 grams of formula (I-5), the component B of 56 grams of formula (II-1), 9 grams of formula (III-1) Component C and 2 grams of C.I. Disperse Yellow 114, 128 grams of sodium lignosulfonate, after adding 600 ml of water to blend, grind and disperse with a grinder, and spray dry to obtain the powdered disperse dye product.

[0051] According to the dyeing method described in Example 1, the polyester textile material is printed and dyed to obtain a dyed fabric with bright navy blue hue, which has excellent fastness to washing, rubbing, perspiration and sunlight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com