Alkali-resistant disperse dye complex

A technology of disperse dyes and complexes, which is applied in the direction of organic dyes, can solve the problems of large pH range changes in weakly acidic dyeing baths, changes in color and light of dyed samples, and uneven dyeing reproduction, so as to achieve dyeing stability and reproducibility. Good presentability, full hue and excellent fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

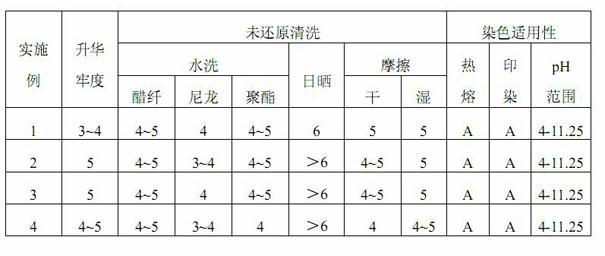

[0064] Weigh 5 grams of prefabricated disperse dye compound products prepared in 1-4 and disperse them in 1 liter of water. After stirring evenly, pipette 20 milliliters and 100 milliliters of water to mix evenly, and adjust the pH value to 11.2 with alkaline agent ADM-14. Heat up to 50°C, put in 5 grams of polyester fiber, raise the temperature to 130°C at a speed of 1.5°C / min, and keep it warm for 45 minutes. Then the temperature was lowered to 60° C., washed with hot water, and dried to obtain Examples 1-4. Adopt national standard GB / T3920, GB / T3931, GB / T5718, GB / T8427 respectively

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com