Dyeing and coating integrated dye dyeing and printing paste-shaped compound and application thereof

A technology of printing paste and composition, which is applied in textile dyeing and printing fields, and can solve problems such as lack of affinity for fibers, poor yellowing resistance, and inability to wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

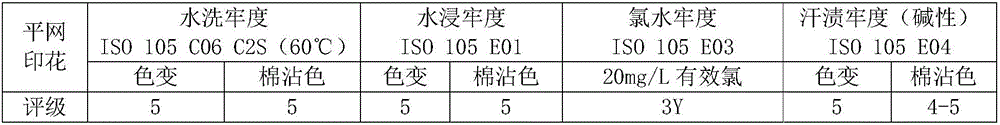

Embodiment 1

[0051] (1) Preparation of dyeing and printing paste B-1

[0052] Add 45g of surfactant BC-50, 50g of sodium lignosulfonate, 30g of ethylene glycol and 525g of water into the dispersion tank, disperse and stir to make it completely dissolved, then add 350g of C.I. Machine, after high-speed dispersion for 2 hours, put the dispersion slurry into a horizontal sand mill for circular grinding, the grinding time is 10 hours, after the grinding is completed, the slurry obtained by grinding is homogenized twice through a high-pressure homogenizer to obtain blue Dye dyeing and printing paste B-1 1000g, fineness d50≤0.5μm, pH=6.8.

[0053] (2) Preparation of Dyeing and Printing Auxiliaries

[0054] Add 227g of deionized water into the dispersing tank, turn on the dispersing machine, and under low-speed stirring, add 15g of surfactant FC-1, 30g of penetrating agent SA-50, 28g of diffusing agent WAX, and silicone softener to the dispersing tank in turn 208C 55g, crosslinking agent CLA-80...

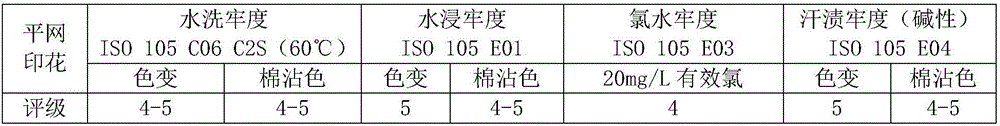

Embodiment 2

[0062] (1) Preparation of dyeing and printing paste Y-1

[0063] Add 45g of surfactant LS-60, 50g of alkaline sodium lignosulfonate, 30g of ethylene glycol and 530g of water into the dispersion tank, disperse and stir to make it completely dissolved, then add 345g of C.I. Disperse Yellow 54 powder, Start the disperser, disperse at high speed for 2 hours, put the dispersed slurry into a horizontal sand mill for circular grinding, the grinding time is 10 hours, after the grinding is completed, the slurry obtained by grinding is homogenized twice through a high-pressure homogenizer to obtain Yellow dyeing and printing paste Y-1 1000g, fineness d50≤0.7μm, pH=7.2.

[0064] (2) dyeing, the preparation of printing auxiliary agent Z-1, with embodiment 1

[0065] (3) Preparation of Dyeing and Printing Concentrate Y-1

[0066] Add 500g of dyeing and printing color paste Y-1 prepared in step (1) into the dispersing tank of the disperser, slowly add 500g of dyeing and printing auxiliary...

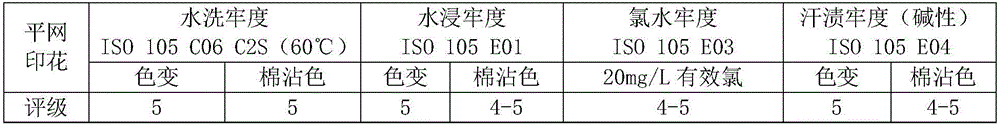

Embodiment 3

[0073] (1) Preparation of dyeing and printing paste R-1

[0074] Add 45g of surfactant LS-70, 50g of alkaline sodium lignosulfonate, 30g of ethylene glycol and 530g of water into the dispersion tank, disperse and stir to make it completely dissolved, then add 345g of C.I. Disperse Red 60 powder, Start the disperser, disperse at high speed for 2 hours, put the dispersed slurry into a horizontal sand mill for circular grinding, the grinding time is 10 hours, after the grinding is completed, the slurry obtained by grinding is homogenized twice through a high-pressure homogenizer to obtain Red dyeing and printing color paste R-1 1000g, fineness d50≤0.7μm, pH=7.2.

[0075] (2) dyeing, the preparation of printing auxiliary agent Z-1, with embodiment 1

[0076] (3) Preparation of Dyeing and Printing Concentrate R-1

[0077] Add 500 g of the dyeing and printing color paste R-1 prepared in step (1) into the dispersing tank of the disperser, slowly add 500 g of dyeing and printing aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com