Thermal sublimation ink as well as direct printing technology and equipment

A thermal sublimation and ink technology, applied in the fields of ink, printing, textiles and papermaking, etc., can solve the problems of high cost of transfer paper, large floor space, and many equipment, so as to reduce the cost of transfer paper, improve production efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

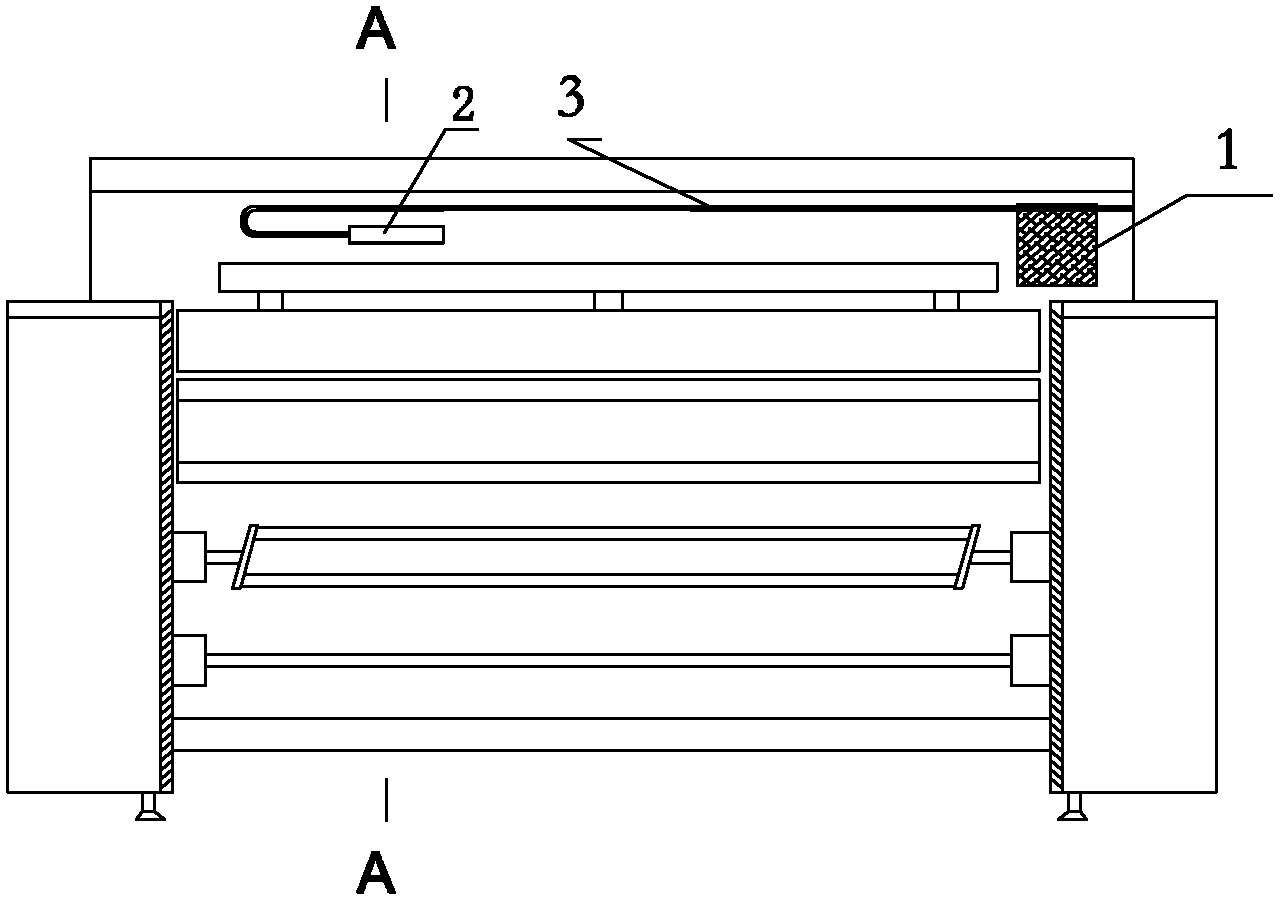

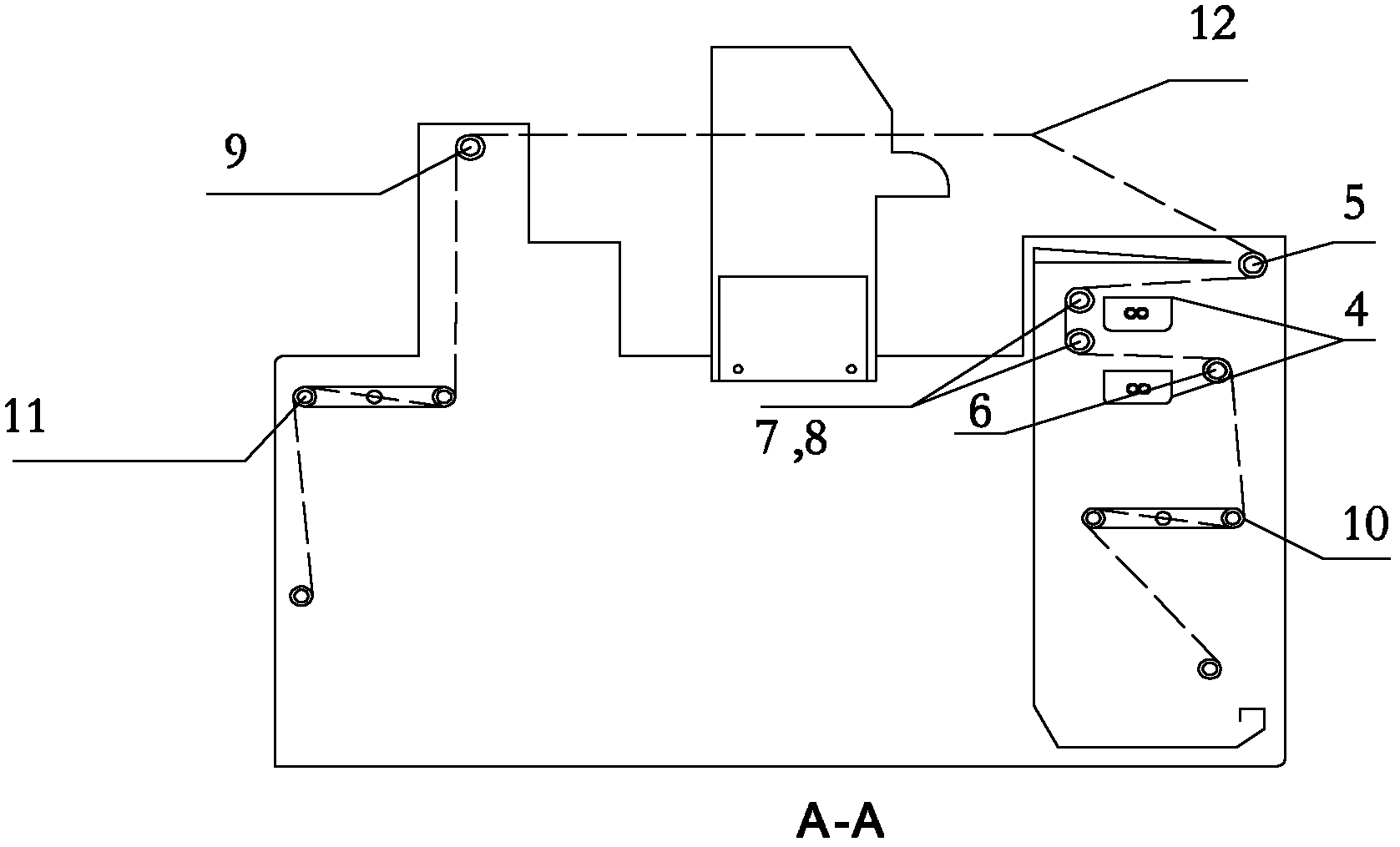

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Sublimation ink direct printing process of the present invention comprises the following steps:

[0014] 1. Apply slurry on the polyester fiber cloth to prevent the sublimation ink from penetrating when it is printed on the surface of the polyester fiber cloth. Use an electric padding car, such as the PB-1 electric uniform padding car of Taiwan Rapid Company. The line speed of the process position is greater than 0 to 18 meters per minute, and the excess rate is 70%, and the excess rate=the weight of the slurry on the cloth / the weight of the cloth itself, and it is dried at no more than 100 ° C according to the prior art.

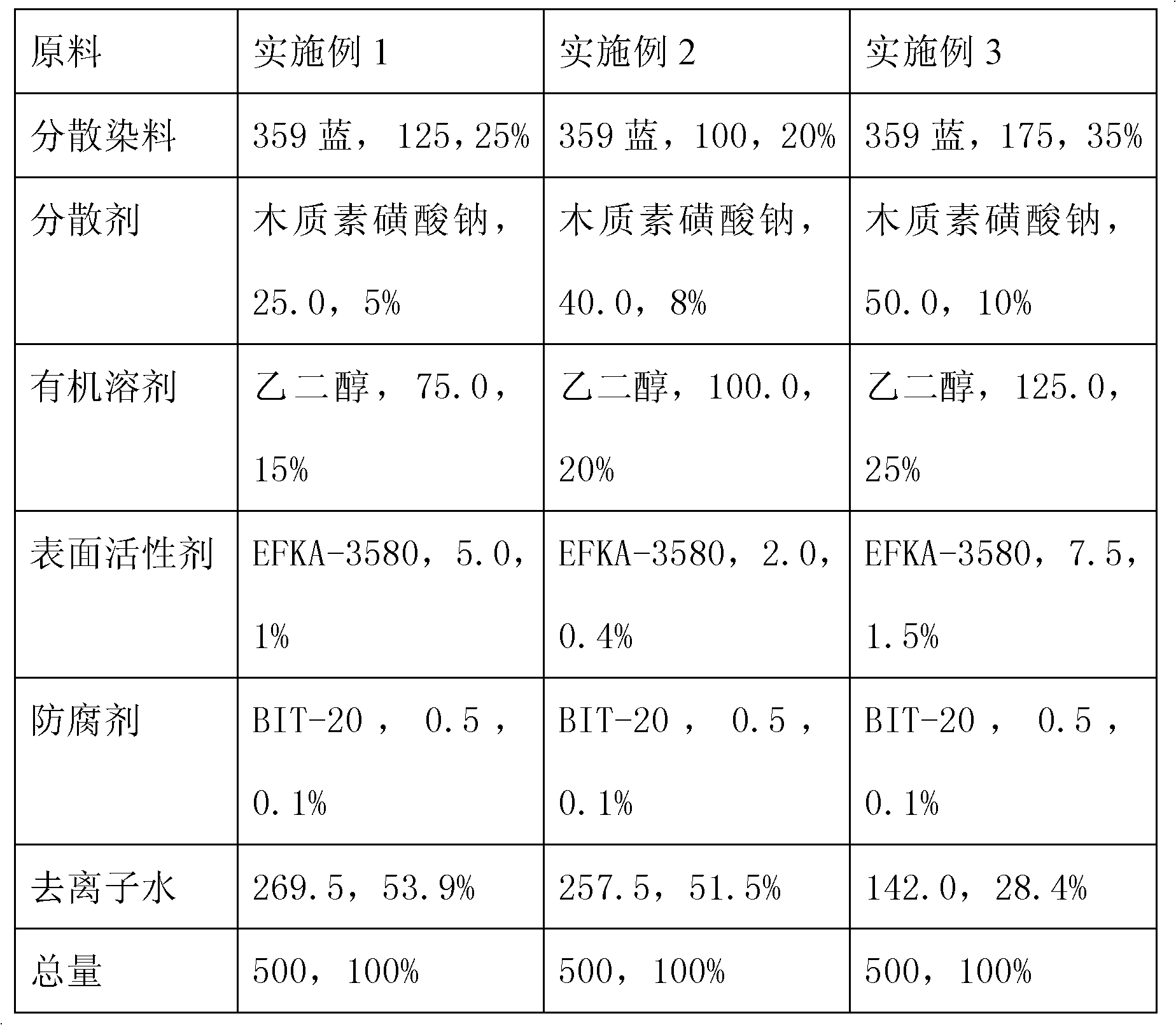

[0015] The slurry is composed of the following mass ratios: 1-2% water-soluble high molecular polymer, 0.5-1% waterproofing agent, 0.5-1% anti-swimming agent, 0.5% anti-reducing agent, 0.1-1% preservative, The rest is water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com