Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

A technology for dispersing active and disperse dyes, applied in the field of dyeing, can solve the problems of no use value, uneven coloring, low color fixing rate, etc., achieve excellent slow release function, good color fastness, avoid influence and hydrolysis damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

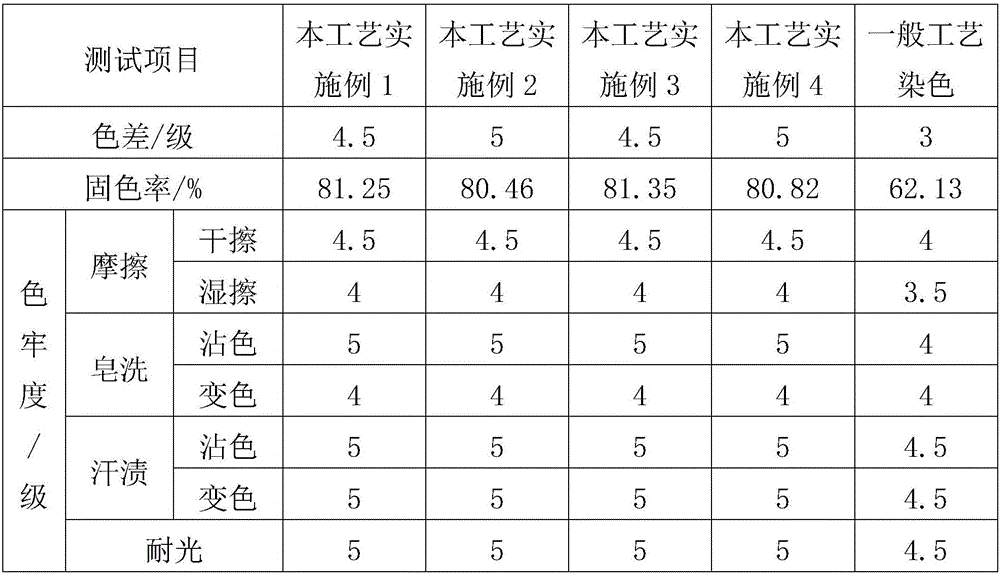

Examples

Embodiment 1

[0022] In the present embodiment, a kind of polyester-cotton microcapsule disperse reactive dye one-bath dyeing process comprises the following steps:

[0023] S1, dyeing and washing, padding the polyester-cotton fabric to be dyed in the dye solution containing microcapsule disperse dye, the dye solution comprising microcapsule disperse dye includes: microcapsule disperse dye 1% (owf), pH buffer 3g / L. Leveling agent 1g / L, adjust the bath ratio to 1:30, enter dyeing at 20°C, heat up to 65°C at a speed of 3°C / min, keep warm for 10min, and then heat up to 130°C at a speed of 1°C / min, Insulate for 25 minutes, and then cool down to 30°C at a rate of 2°C / min. The microcapsule disperse dye is obtained by using chitosan as the carrier of the disperse dye, and then cross-linked and solidified. The specific preparation method includes: mixing the disperse dye and the shell Add the polysaccharide to the acetic acid solution with a concentration of 0.5wt%, stir evenly, add liquid paraffi...

Embodiment 2

[0027] In the present embodiment, a kind of polyester-cotton microcapsule disperse reactive dye one-bath dyeing process comprises the following steps:

[0028]S1, dyeing and washing, padding the polyester-cotton fabric to be dyed in the dye solution containing microcapsule disperse dye, the dye solution comprising microcapsule disperse dye includes: microcapsule disperse dye 5% (owf), pH buffer 1g / L. Leveling agent 2g / L, adjust the bath ratio to 1:10, enter dyeing at 30°C, heat up to 75°C at a speed of 2°C / min, keep warm for 5min, and then heat up to 110°C at a speed of 2°C / min, Insulate for 45 minutes, then cool down to 40°C at a rate of 1.5°C / min. The microcapsule disperse dye is obtained by using chitosan as the carrier of the disperse dye, and then cross-linked and solidified. The specific preparation method includes: mixing the disperse dye and the shell The polysaccharide was added to the acetic acid solution with a concentration of 3wt% and stirred evenly, then liquid ...

Embodiment 3

[0032] In the present embodiment, a kind of polyester-cotton microcapsule disperse reactive dye one-bath dyeing process comprises the following steps:

[0033] S1, dyeing and washing, padding the polyester-cotton fabric to be dyed in the dye solution containing microcapsule disperse dye, the dye solution comprising microcapsule disperse dye includes: microcapsule disperse dye 2% (owf), pH buffer 2g / L. Leveling agent 1.5g / L, adjust the bath ratio to 1:20, enter dyeing at 25°C, heat up to 70°C at a speed of 2.5°C / min, keep warm for 7 minutes, and then heat up to 120°C at a speed of 1.5°C / min , keep warm for 35min, then cool down to 35°C at a speed of 1.7°C / min, the microcapsule disperse dye adopts chitosan as the carrier of the disperse dye, and then obtains it through cross-linking and solidification. The specific preparation method includes: combining the disperse dye and Chitosan was added to 1.5wt% acetic acid solution and stirred evenly, then liquid paraffin and Tween-80 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com