Textile fabric dip-dye device

A technology for textile and dyeing, applied in the field of textile processing, can solve problems such as poor drying effect and inability to dye patterns, and achieve the effects of reducing processes, avoiding precipitation, and saving dye liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

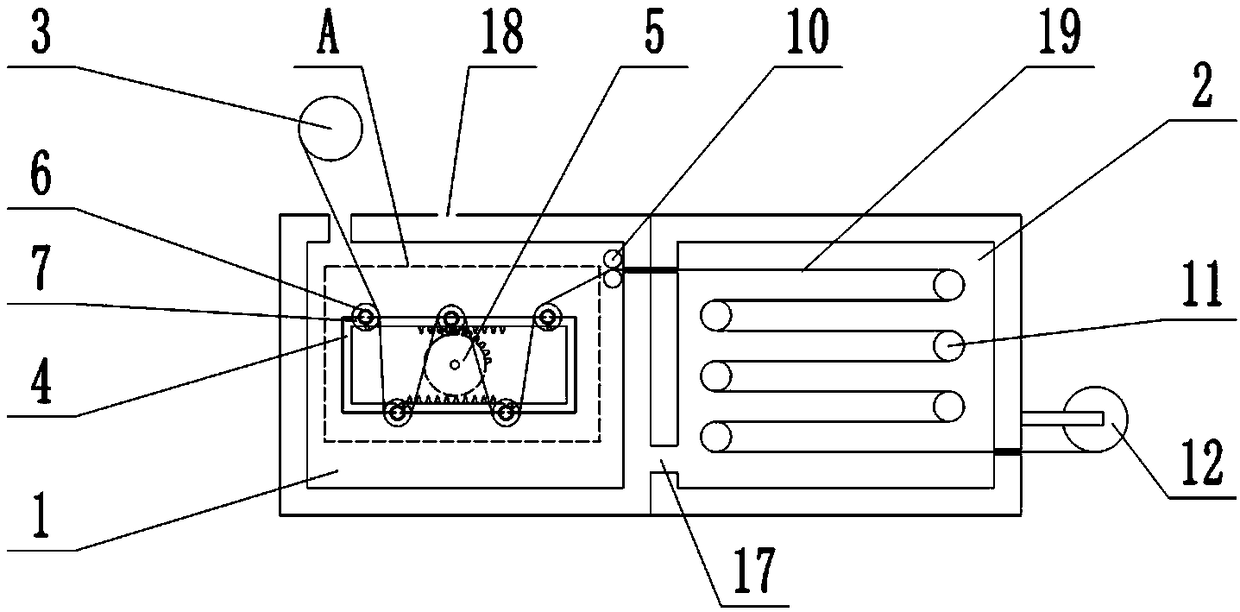

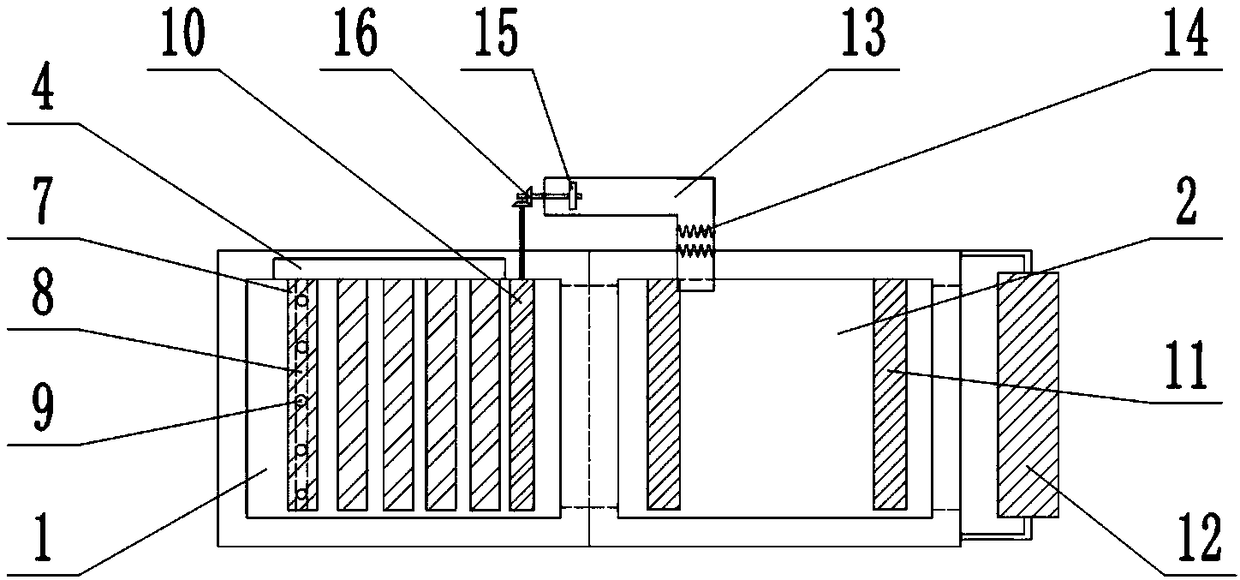

[0028] basically as figure 1 Shown: an exhaust dyeing device for textile fabrics, comprising a first cylinder 1 and a second cylinder 2 side by side.

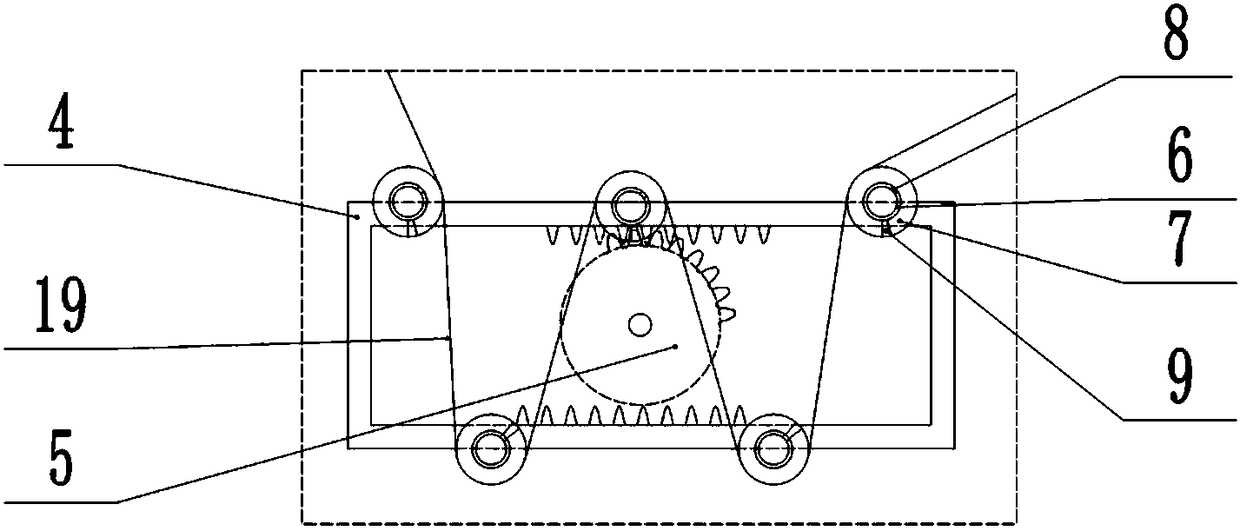

[0029] A raw material roll 3 is arranged above the first cylinder 1 , and a feed inlet is arranged on the top wall of the first cylinder 1 opposite to the raw material roll 3 . The side wall of the first cylinder body 1 is hollow, and the side wall inner surface of the first cylinder body 1 is provided with a chute, and a rectangular frame 4 is slidably connected in the chute, as figure 2 , image 3 As shown, the inner side of the upper and lower frame of the rectangular frame 4 is fixed with a rack, and the rectangular frame 4 is provided with an incomplete gear 5 meshing with the rack, and the incomplete gear 5 is driven by a motor. Three rotating shafts 6 are fixed on the upper frame of the rectangular frame 4, and two rotating shafts 6 are fixed on the lower frame of the rectangular frame 4, and the intervals between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com