Temperature controlling method for hot blast drying device used in warp sizing device

A temperature control method and warp sizing technology, which are applied in the direction of temperature control, progressive dryer, non-electric variable control, etc., can solve the problem of large power consumption of electric heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

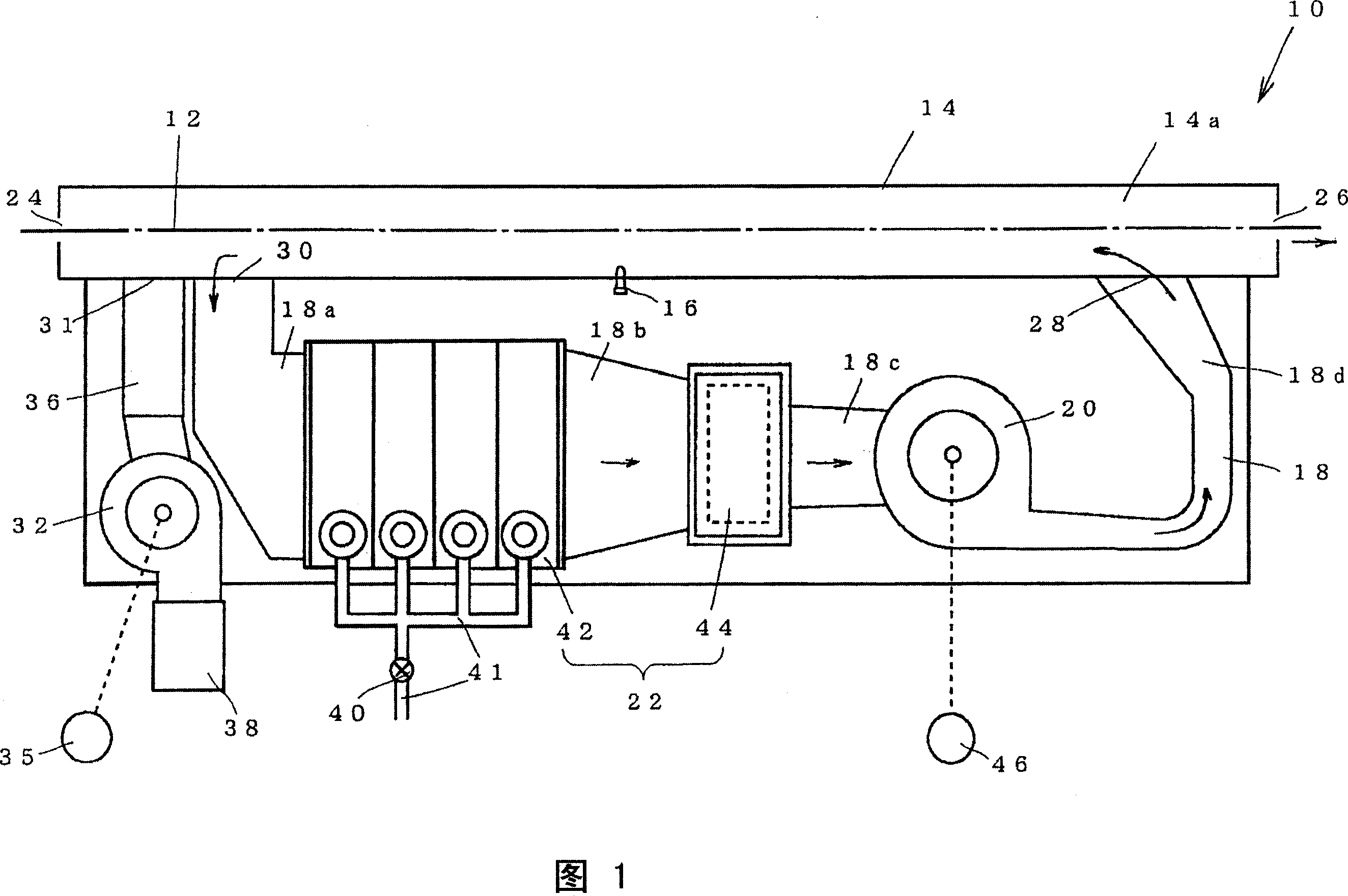

[0029] A specific mode for implementing the present invention will be described below using the drawings. Referring to Fig. 1, the hot air drying device 10 used in the warp yarn sizing device makes the sheet-like warp yarn 12 in the wet state 12 that is sized in the previous process (not shown) pass through the inside of the drying chamber 14 that sends hot air to dry. , In the subsequent post-process, the warp yarns are further dried by contacting and passing through an air cylinder dryer (not shown), and wound into warp yarn bundles (not shown).

[0030] In general, the hot air drying device 10 has a box-shaped drying chamber 14 and an air heater 22, and the air heater 22 is arranged on the entire air supply path 18 passing through the inside of the drying chamber 14. The air blower 20 heats the air supplied to the drying chamber 14, and is comprised by the some heater arrange|positioned.

[0031] The drying chamber 14 extends along the warp traveling direction, has an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com