Device for weaving with washing and drying functions

A technology of equipment and functions, applied in the field of textile equipment, to achieve the effects of easy drying, pollution reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

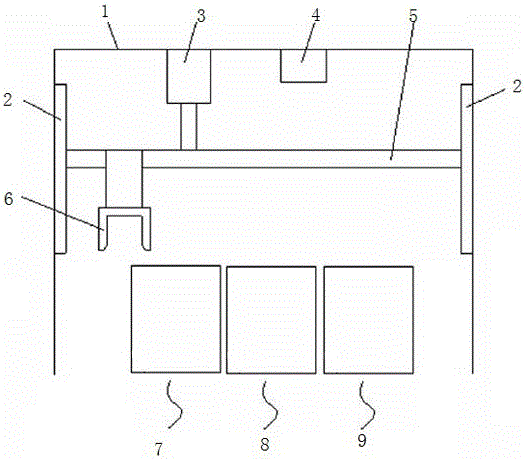

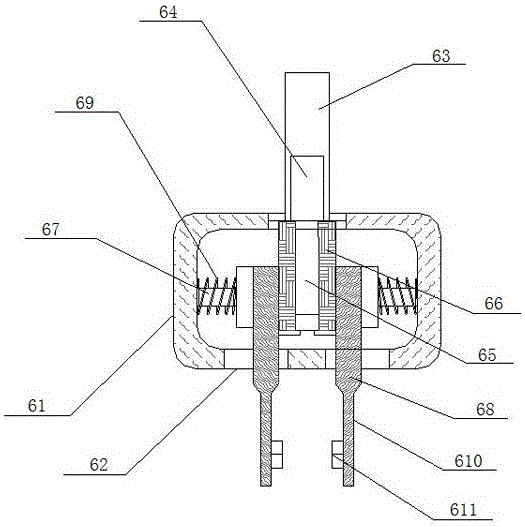

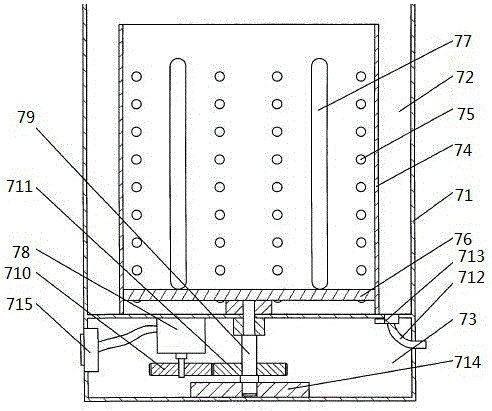

[0019] Such as figure 1 As shown, a kind of textile equipment with cleaning and drying functions includes a frame 1 and a longitudinal guide rail 2, a cylinder 3, and a controller 4 arranged on the frame 1, and the cylinder 3 is connected with a transverse guide rail 5; The transverse guide rail 5 is vertically connected between the two longitudinal guide rails 2 to form an "H" shape. The transverse guide rail 5 is connected with a manipulator 6; A fabric cleaning mechanism 7, a fabric filtering mechanism 8, and a fabric drying mechanism 9 are provided; figure 2 As shown, the manipulator 6 includes a claw body 61, the claw body 61 is a hollow structure, its bottom end is provided with a claw through hole 62, and the top end is connected with a fixed rod 63; The guide rails 5 are connected, and a motor 64 is arranged in the fixed rod 63; the transmission shaft 65 of the motor 64 passes through the claw body 61 and is connected with a cam 66, and the cam 66 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com