Mineral pigment grinding device for art pigment preparation

A technology of grinding device and minerals, applied in grain processing, transportation and packaging, loading/unloading, etc., can solve the problems of poor grinding effect of grinding device and affect the quality of prepared pigment products, so as to improve product quality and improve grinding effect , to avoid the effect of raw material residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

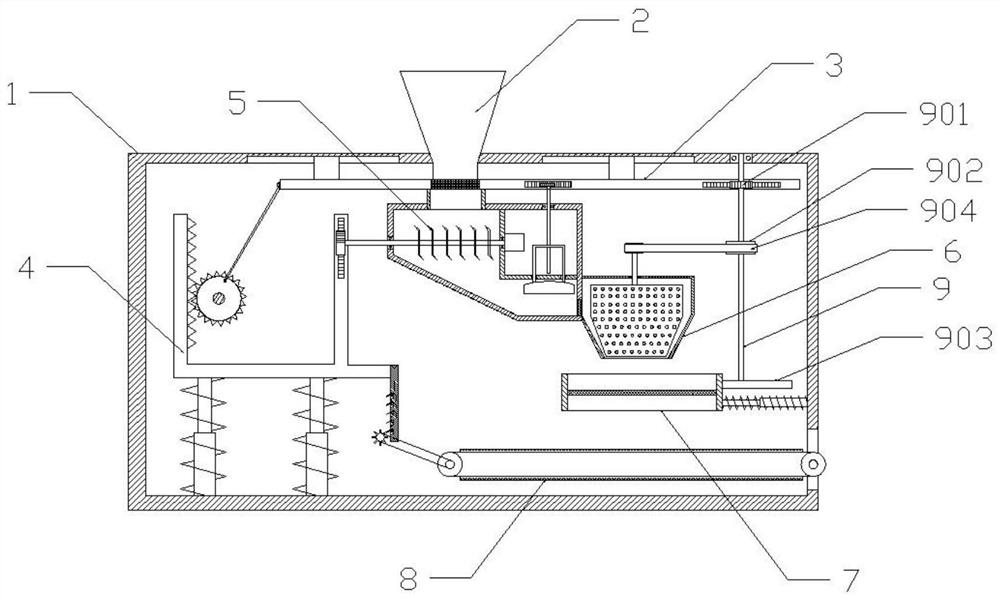

[0041] This embodiment is a mineral pigment grinding device for the preparation of art pigments, comprising a stand 1, a feed hopper 2 is connected to the center of the top of the stand 1, a stopper mechanism 3 is provided on the top of the inner cavity of the stand 1, and the stand The left side of the inner cavity of 1 is provided with a transmission mechanism 4, and the middle part of the inner cavity of the stand 1 is provided with a crushing mechanism 5, and the right end of the crushing mechanism 5 is connected with a grinding mechanism 6, and the bottom of the grinding mechanism 6 is provided with a sieving mechanism 7, and the sieving material The bottom of mechanism 7 is provided with discharge mechanism 8, and the right end of discharge mechanism 8 stretches out stand 1.

[0042] The specific steps of the method for using the mineral pigment grinding device for preparing art pigments are as follows:

[0043] S1. Place the stand 1 horizontally on the ground, and intro...

Embodiment 2

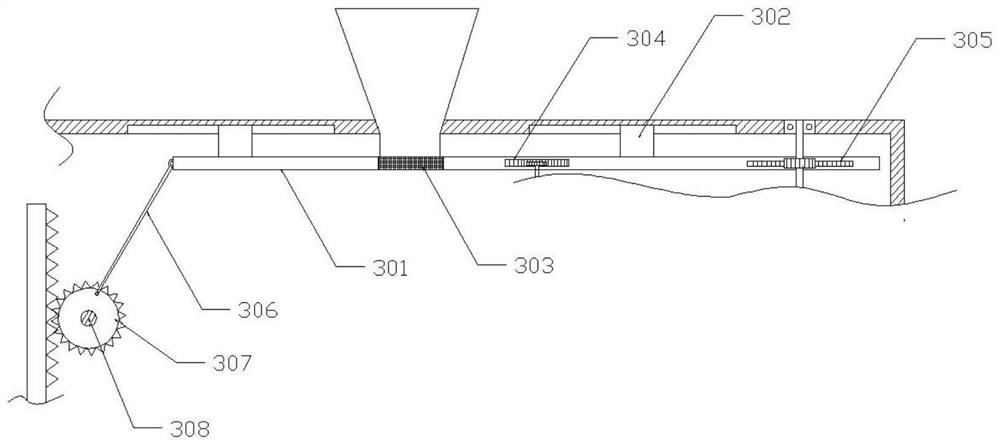

[0049] On the basis of Embodiment 1, the material blocking mechanism 3 includes a slide bar 301, a slider 302, a material blocking plate 303, a first rack 304, a second rack 305, a movable rod 306, a spur gear 307 and a rotating shaft 308. The top of the inner cavity of the rack 1 is provided with a chute matching with the slider 302, the lower end of the slider 302 is fixedly connected to the slide bar 301, the material retaining plate 303 is located in the middle of the slide bar 301, and the upper end of the material retaining plate 303 is attached to the bottom of the feed hopper 2 , the first rack 304 and the second rack 305 are connected to the front end of the slide bar 301, the second rack 305 is located on the right side of the first rack 304, the right end of the movable rod 306 is hinged to the slide rod 301, and the left end of the movable rod 306 is hinged to the spur gear 307 front end face, the center of the spur gear 307 is connected with a first rotating shaft ...

Embodiment 3

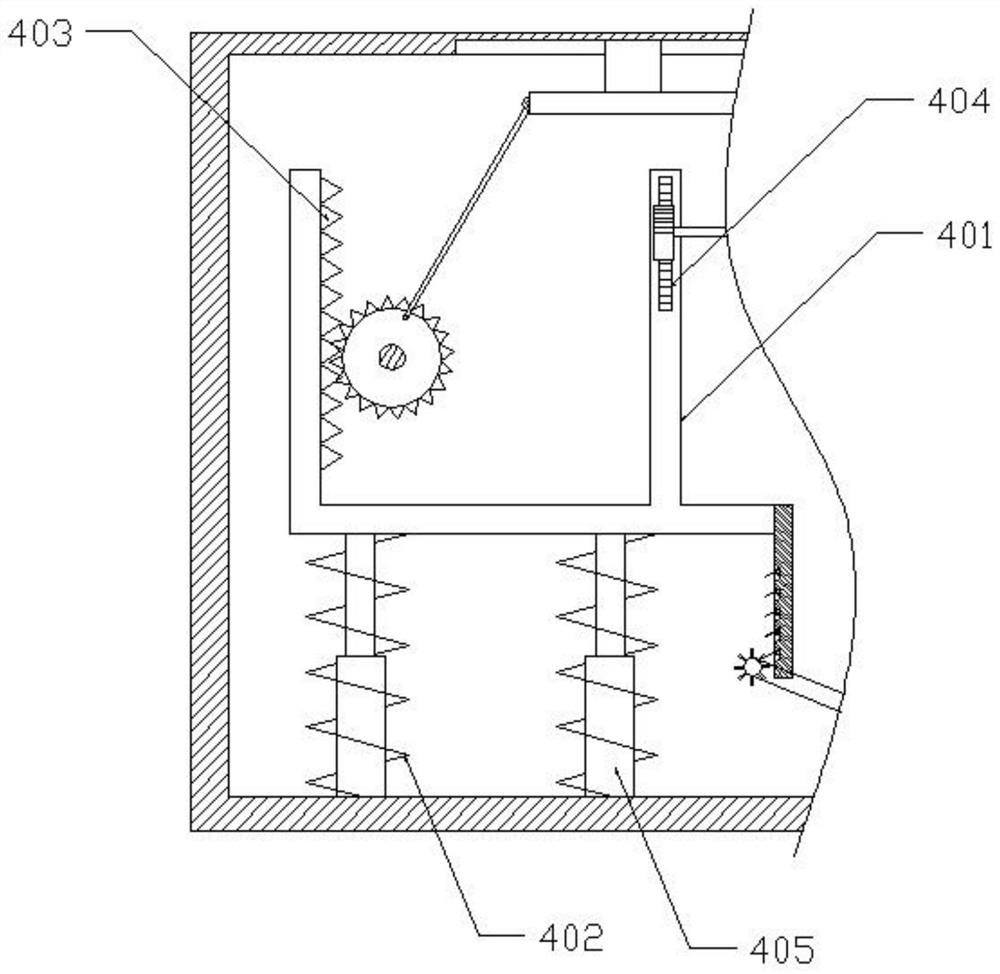

[0056] On the basis of Embodiment 2, the grinding mechanism 6 includes a grinding shell 601, the top of the left side wall of the grinding shell 601 communicates with the material guide port 512, the bottom of the grinding shell 601 is provided with a discharge port 602, and the grinding shell 601 The top center is rotatably connected with a second rotating shaft 603, the top of the second rotating shaft 603 is connected with a first pulley 604, and one end of the second rotating shaft 603 extending into the inner cavity of the grinding shell 601 is connected with a grinding roller 605, and the outer surface of the grinding roller 605 Wear-resistant bumps 606 are evenly distributed on the surface.

[0057] The screening mechanism 7 includes a material receiving frame 701, the material receiving frame 701 is located directly below the discharge port 602, and the inside of the material receiving frame 701 is connected with a second filter screen 702, between the right side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com