Device for processing flat steel

A flat steel and support plate technology, applied in the field of plate processing, can solve problems such as low work efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

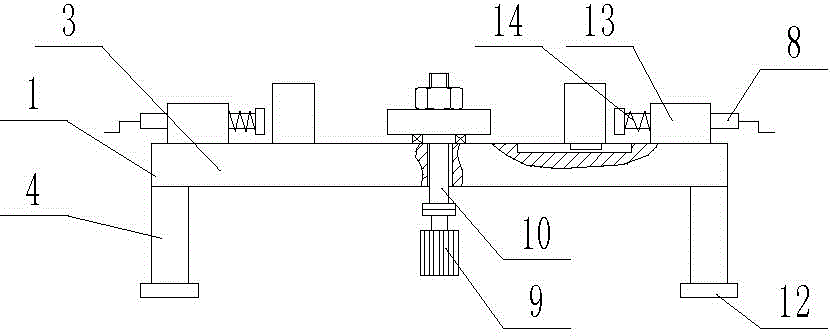

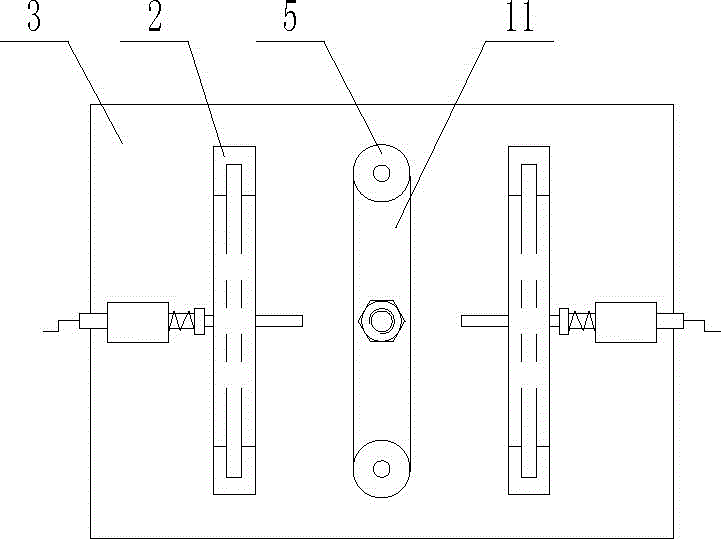

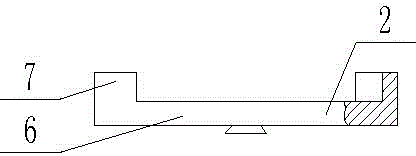

[0017] The reference signs in the drawings of the description include: support base 1, clamping plate 2, support plate 3, support column 4, roller 5, bottom plate 6, deck 7, screw rod 8, motor 9, rotating shaft 10, rotating rod 11 , Shock absorbing plate 12, sleeve 13, spring 14.

[0018] The embodiment is basically as attached figure 1 , figure 2 , image 3 Shown: a device for processing flat steel, including a support base 1, a power system and a clamping plate 2, the clamping plate 2 is interactively connected with the support base 1; the support base 1 includes a support plate 3 and a support column 4, and the support column 4 Fixedly connected with the support plate 3, the support plate 3 is a cuboid, the middle part of the support plate 3 is provided with a through hole, the support plate 3 is provided with two dovetail grooves, the clamping plate 2 includes a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com