Wood heat treatment method

A technology of wood heat treatment and stage heat treatment, which is applied in the direction of wood heat treatment, wood treatment, wood treatment details, etc. It can solve the problems of low heat treatment temperature, fast heat treatment speed and high treatment temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] 1. Material handling

[0183] 1A. Material stacking

[0184] The Chinese fir plank sawn into 4500mm * 400mm * 30mm (length * width * thickness) is stacked according to any one of the timber stacking forms disclosed in the field of wood drying. There is a layer of spacers with a thickness of 30mm and a width of 25mm between adjacent fir boards on both sides, and the distance between two adjacent spacers in the same layer of spacers is 500mm, and the spacer is two The distance between two end faces is 50mm;

[0185] In the embodiment of the invention, the spacer with a thickness of 30 mm and a width of 25 mm is used as an example for illustration. Spacers with other dimensions of 30 ± 5 mm in thickness and 25 ± 5 mm in width are also suitable for the present invention.

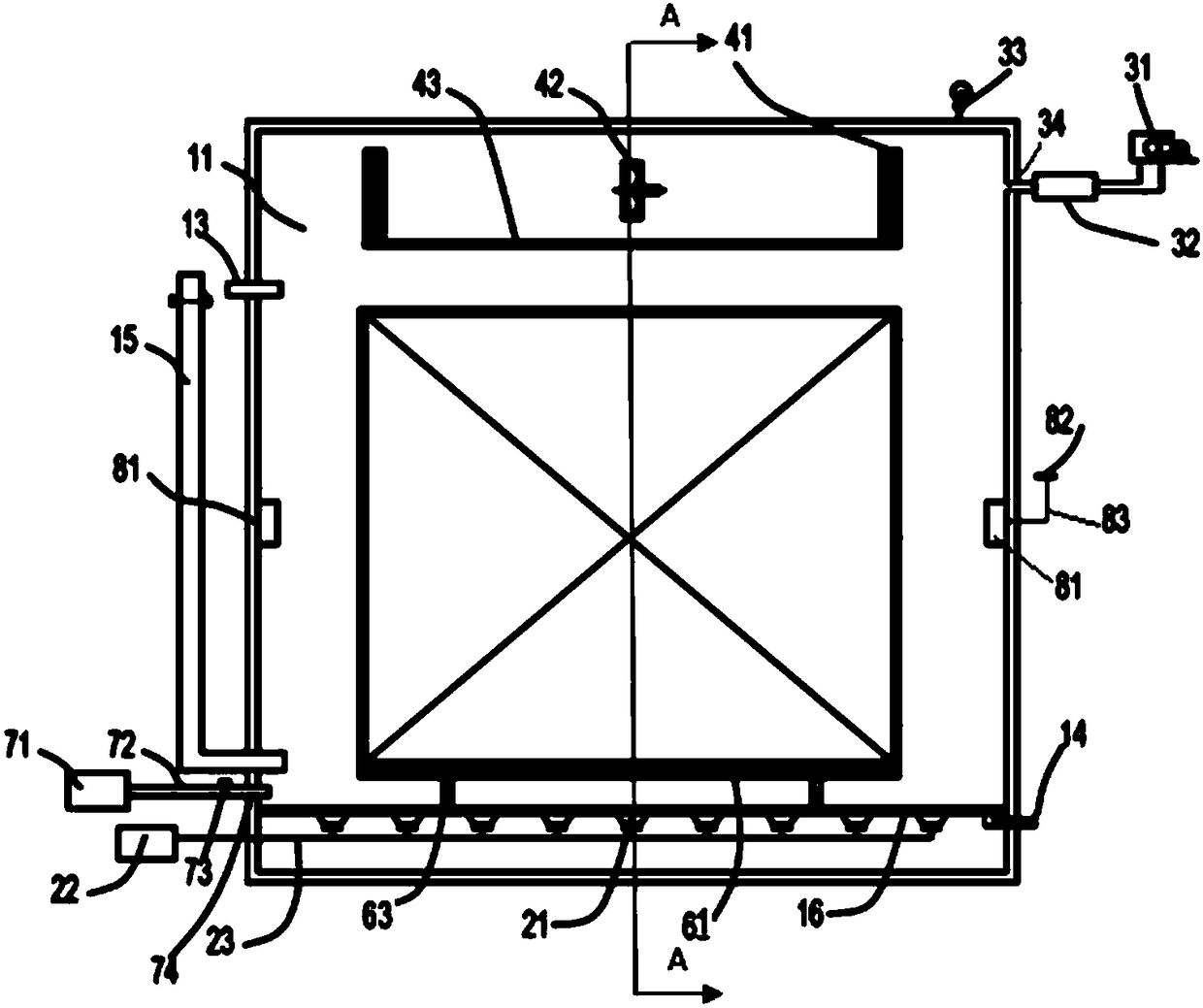

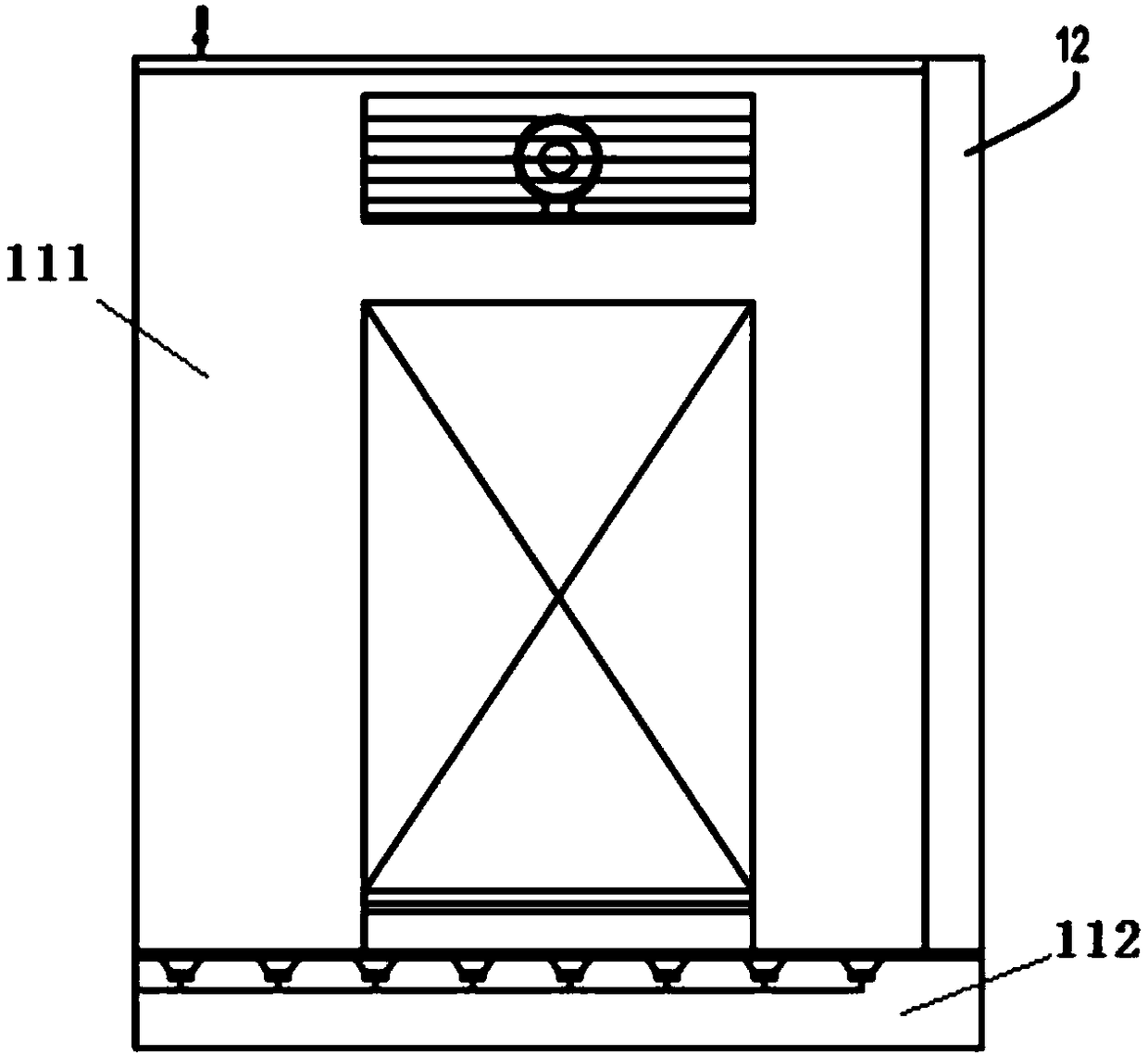

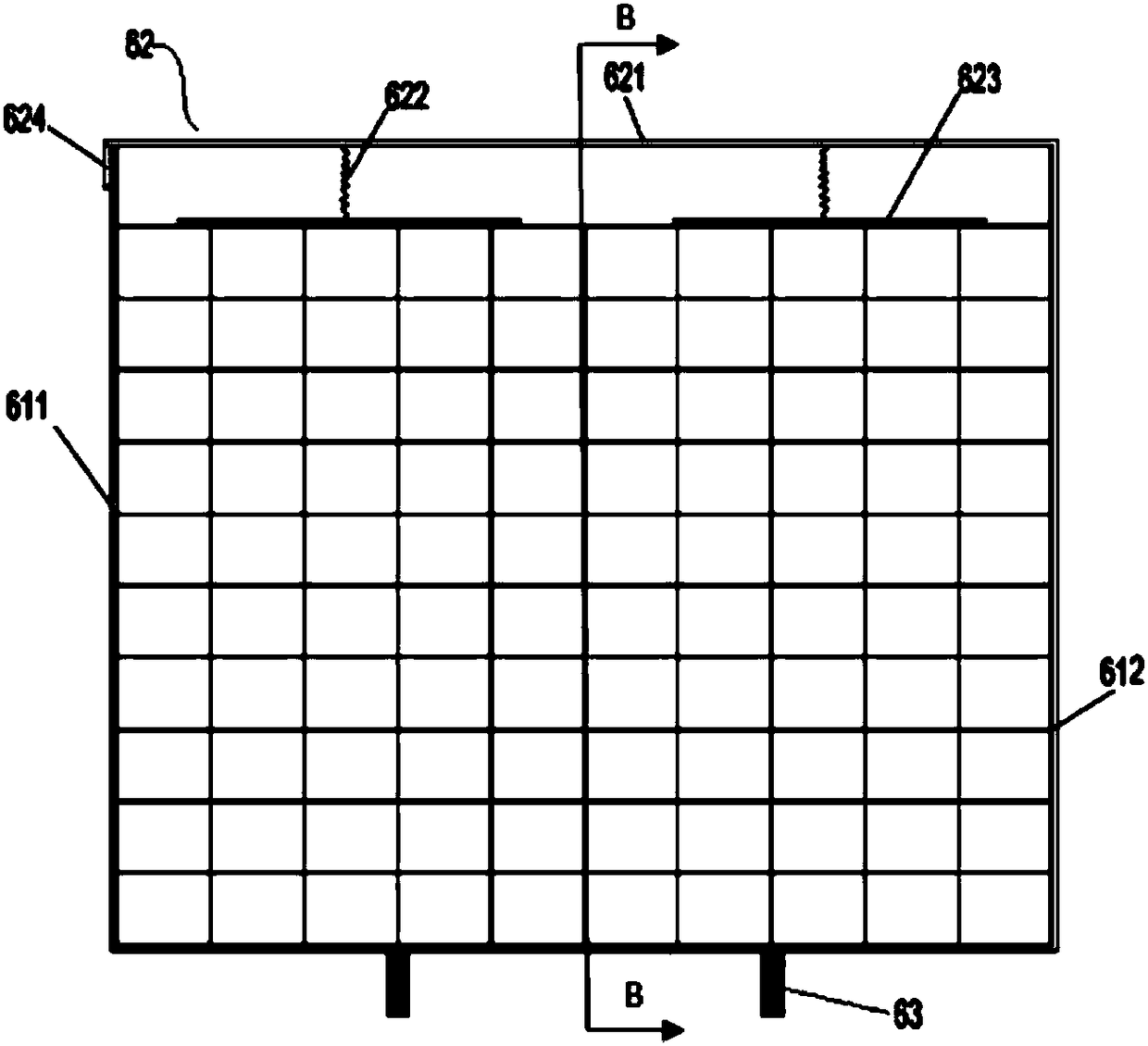

[0186] 1B. Fixed material stack

[0187] The Chinese fir pile is placed inside the frame of the material loading system, the fixing assembly 62 is pressed down, the four sides of the mesh top cover are...

Embodiment 2

[0206] Except step 2A-2) where the ultrasonic power is 0.1W / cm 2 Frequency is 56kHz; Ultrasonic pretreatment time 180min, according to wood thickness meter, timber ultrasonic pretreatment time is 60min / cm (thick); Step 2B-1) in the modified treatment liquid is the zinc chloride that mass concentration is 15%; In step 2B-2), the absolute pressure in the treatment chamber is maintained at 0.01 MPa; the ultrasonic power is 0.1 W / cm 2 Frequency is 56kHz; 1.5h between the ultrasonic modification treatment under the vacuum state, by wood thickness meter, the ultrasonic modification treatment time under the vacuum state of the wood is 0.5h / cm (thick); repeat step 2B in step 2B-4) -2), 2B-3) were treated 3 times; the ultrasonic modification treatment time under each vacuum state was 1.5h, the ultrasonic treatment time was 1.5h, and the ultrasonic modification treatment time of wood was 0.5h per centimeter of wood thickness / cm (thick); the total time of ultrasonic modification treatm...

Embodiment 3

[0210] Except step 2A-2) the ultrasonic power is 20W / cm 2 Frequency is 25kHz; Ultrasonic pretreatment time 15min, according to wood thickness meter, wood ultrasonic pretreatment time is 5min / cm (thick); In step 2B-1), the modified treatment solution is zinc chloride whose mass concentration is 1%; In step 2B-2), the absolute pressure in the treatment chamber is maintained at 0.005MPa; the ultrasonic power is 20 W / cm 2 Frequency is 25kHz; Ultrasonic modification treatment time 9h under the vacuum state, by wood thickness meter, the ultrasonic modification treatment time under the vacuum state of wood is 3h / cm (thick); Repeat step 2B-2 in step 2B-4) ), 2B-3) for 2 times; the ultrasonic modification treatment time under each vacuum state is 9h, the ultrasonic treatment time is 9h, and the wood ultrasonic modification treatment time is 3h / cm (thickness) according to the thickness of each centimeter of wood ; The total time of ultrasonic modification treatment under the vacuum sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com