Radial ultrasonic vibration auxiliary cutting device

A cutting device and ultrasonic vibration technology, which is applied to the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of complex structure, high cost, inconvenient disassembly and assembly of the device, and achieve the expansion of processing range, simple structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

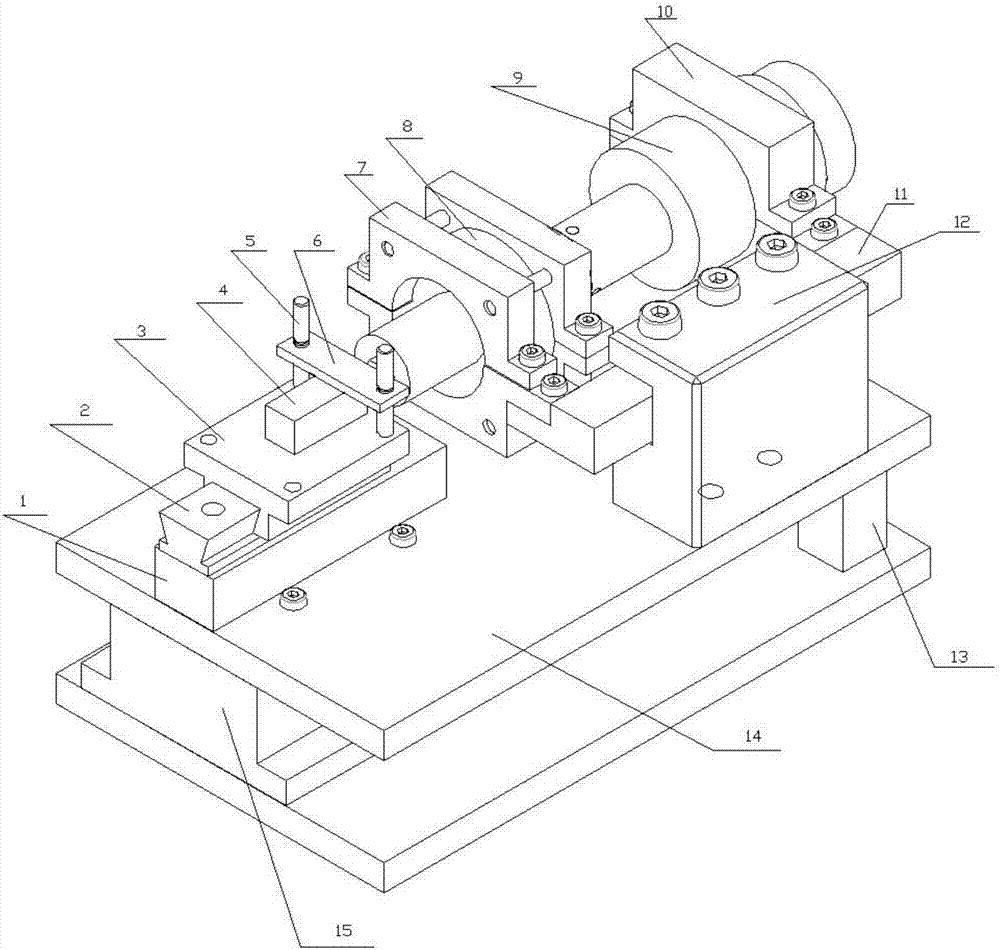

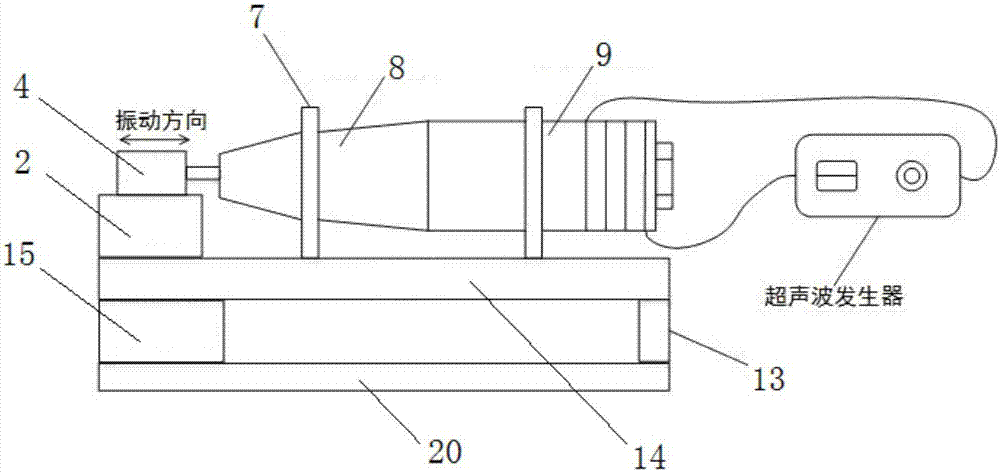

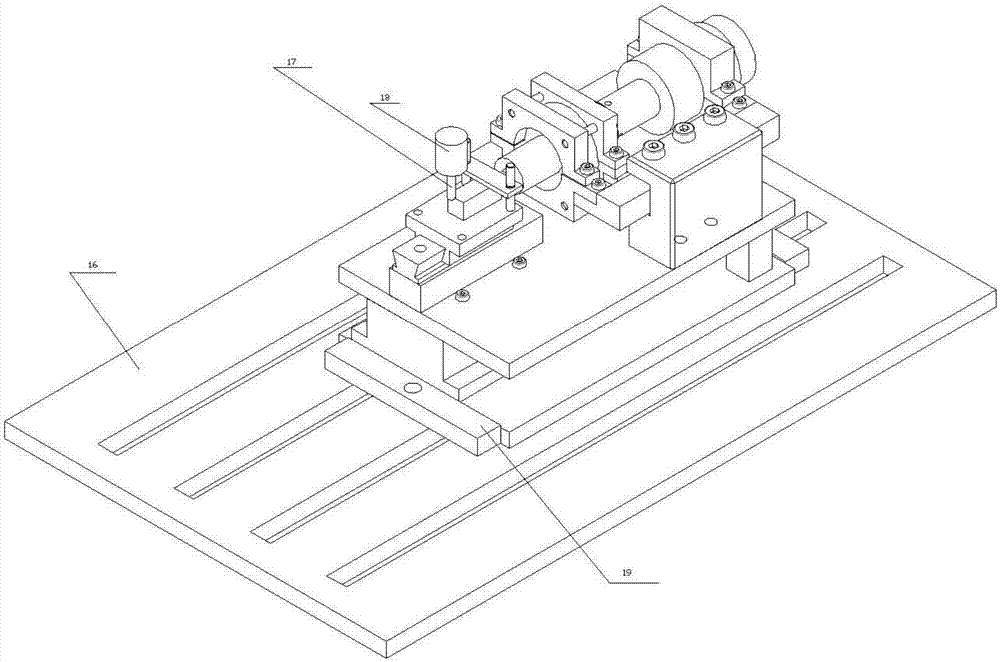

[0035] Use process: In this experiment, the ZJK7532A drilling and milling machine produced by Wuhan No. 4 Machine Tool Factory was used for radial ultrasonic vibration-assisted cutting. The experiment used a high-speed steel straight shank end mill with a diameter of 8mm to process No. 45 steel material, and the workpiece size was 30mm*30mm *60mm. First, the transducer of the present invention is connected to the generator through a wire, and the ultrasonic vibration device is fixed on the fixed block through a cantilever beam device, and the radial ultrasonic vibration is realized by adding an ultrasonic vibration and a rotary motion of the tool in the feed direction Vibration cutting process.

[0036] After starting the ultrasonic generator, the ultrasonic generator transmits the 20kHz ultrasonic excitation signal to the horn 8 through the transducer, and the horn 8 transmits the ultrasonic excitation signal to the workpiece 4, so that the workpiece 4 generates 20kHz in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com