Electrophoresis spraying machine device for automobile accessories

A technology for auto parts and spraying machines, applied in spraying booths, spraying devices, etc., can solve the problems of inability to improve the spraying effect, single function, complex structure, etc., and achieve the effect of increasing internal cleaning functions, facilitating fixed processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

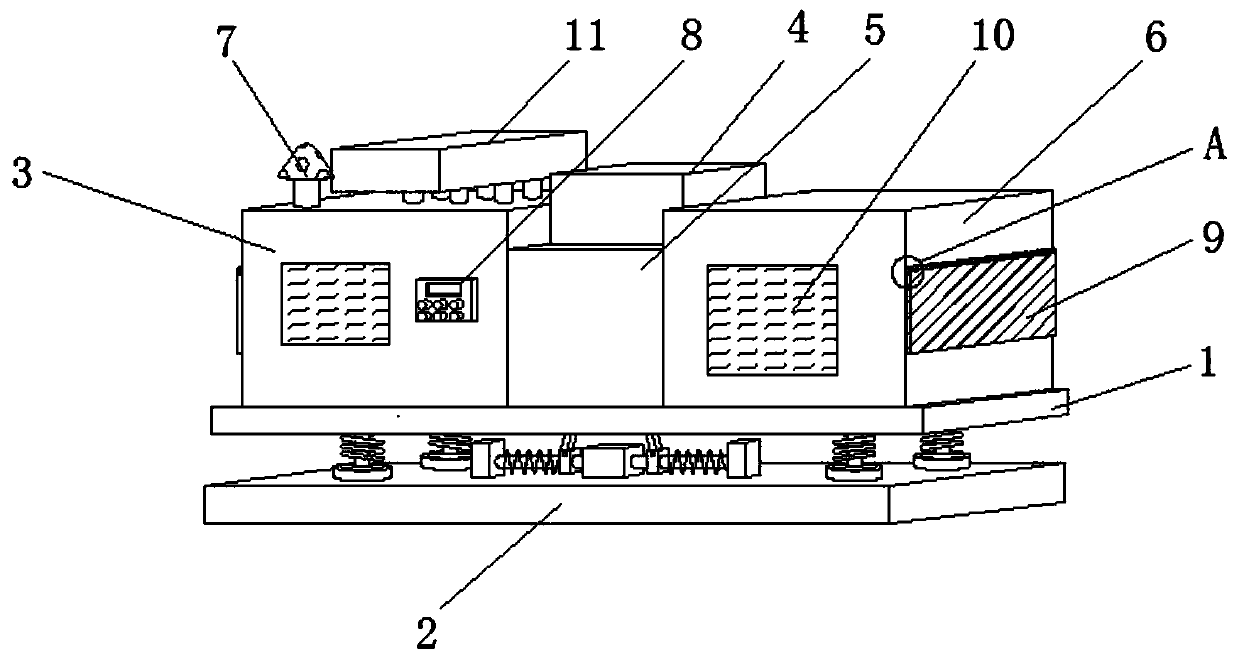

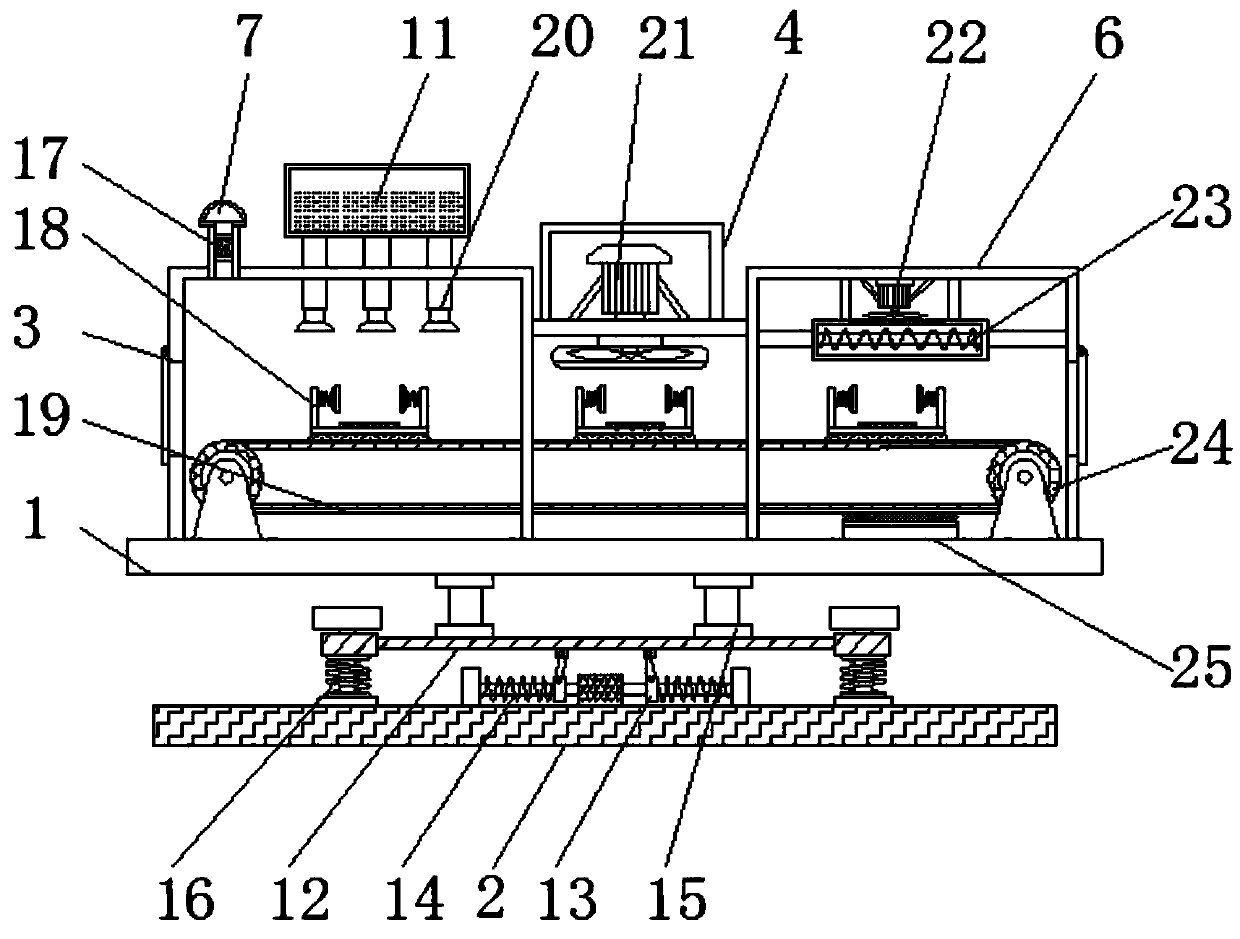

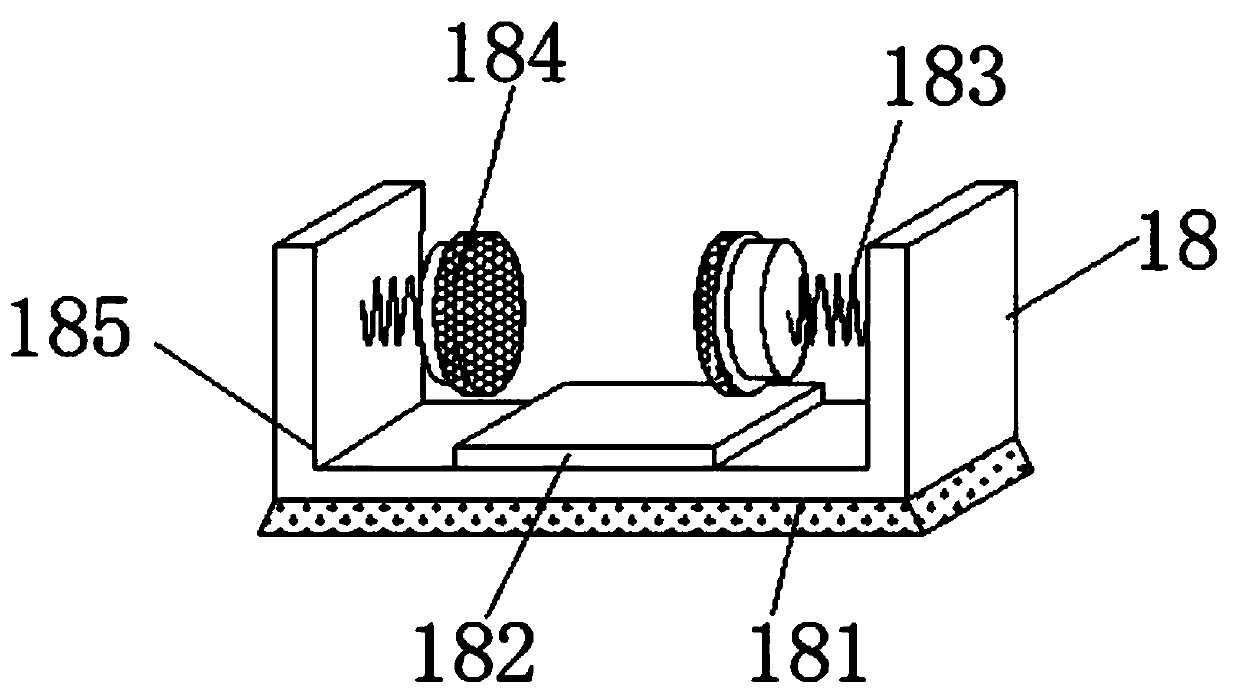

[0019] see Figure 1~5 , in an embodiment of the present invention, an electrophoretic spraying machine equipment for auto parts, comprising a support plate 1, a base 2 is provided at the lower end of the support plate 1, and a spray booth 3 is provided at the upper end of the support plate 1, and one side of the spray booth 3 Wind blowing chamber 5 is provided, and the front surface of spray booth 3 is provided with control panel 8, and the upper end of spray booth 3 is provided with ventilation hole 7, and the inside of spray booth 3 is provided with fixing device 18, and the upper end of fixing device 18 is provided with Electric spray gun 20, and the lower end of fixing device 18 is provided with conveyer belt 19, and one side of ventilation hole 7 is provided with paint case 11, and the inside of ventilation hole 7 is provided with activated carbon filter screen 17, and the upper end of wind blowing chamber 5 is provided with motor box 4, and one side of the wind blowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com