Plastic vest bag production device

A technology for production equipment and vest bags, which is applied in the field of production equipment for plastic vest bags, can solve problems such as plastic bags floating around, poor sanitary environment in plastic bag production workshops, and affecting the normal operation of plastic bag production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

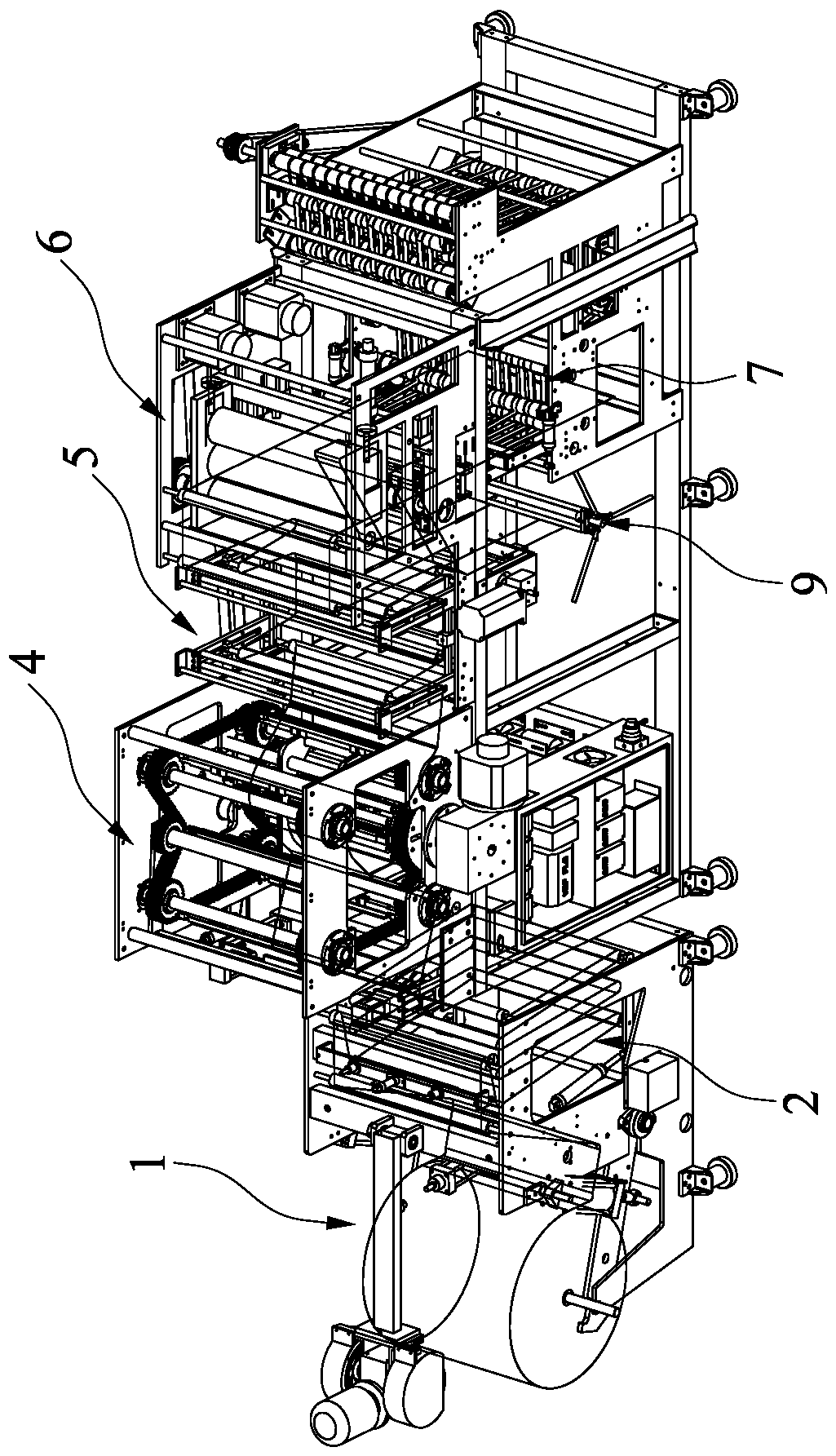

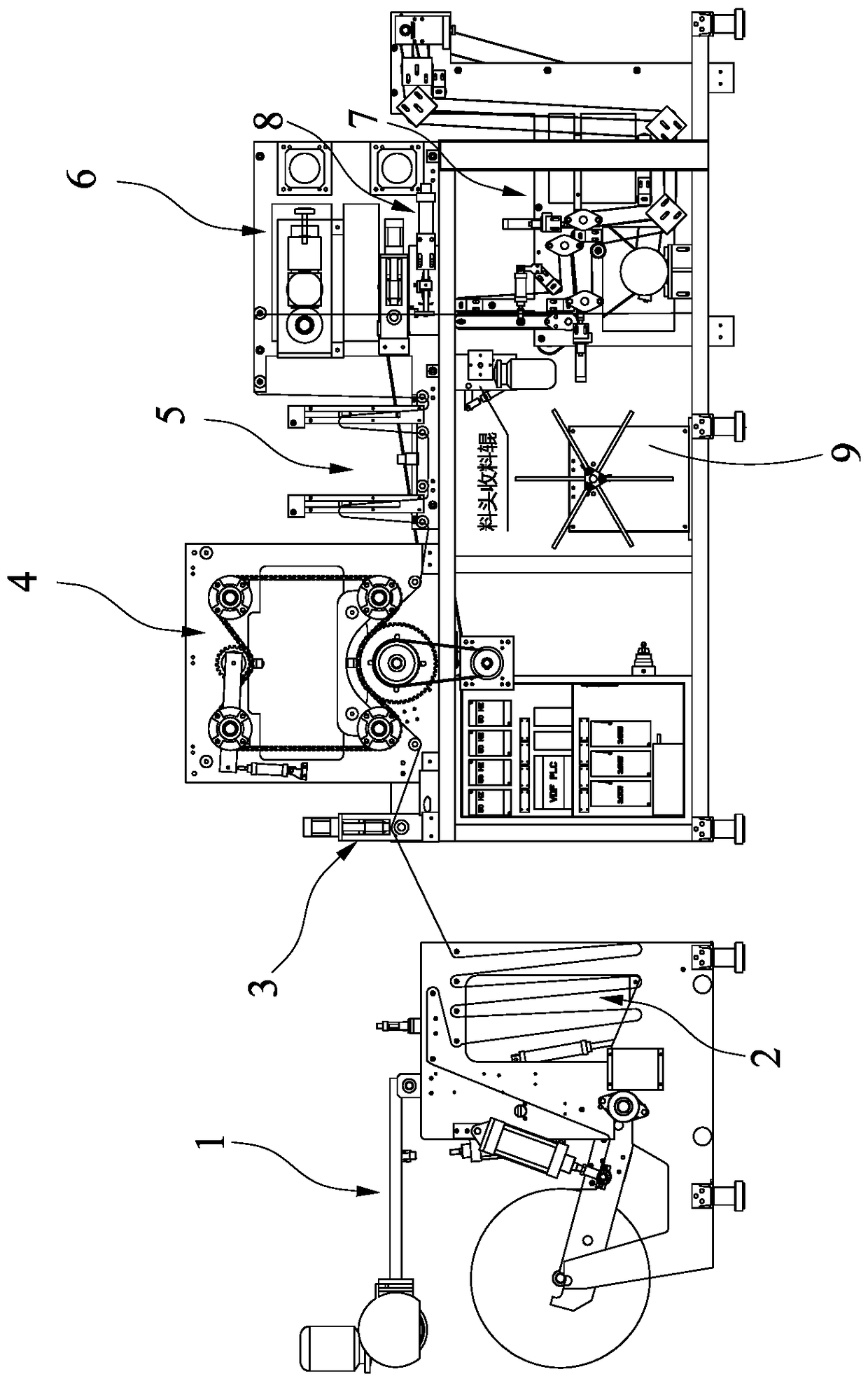

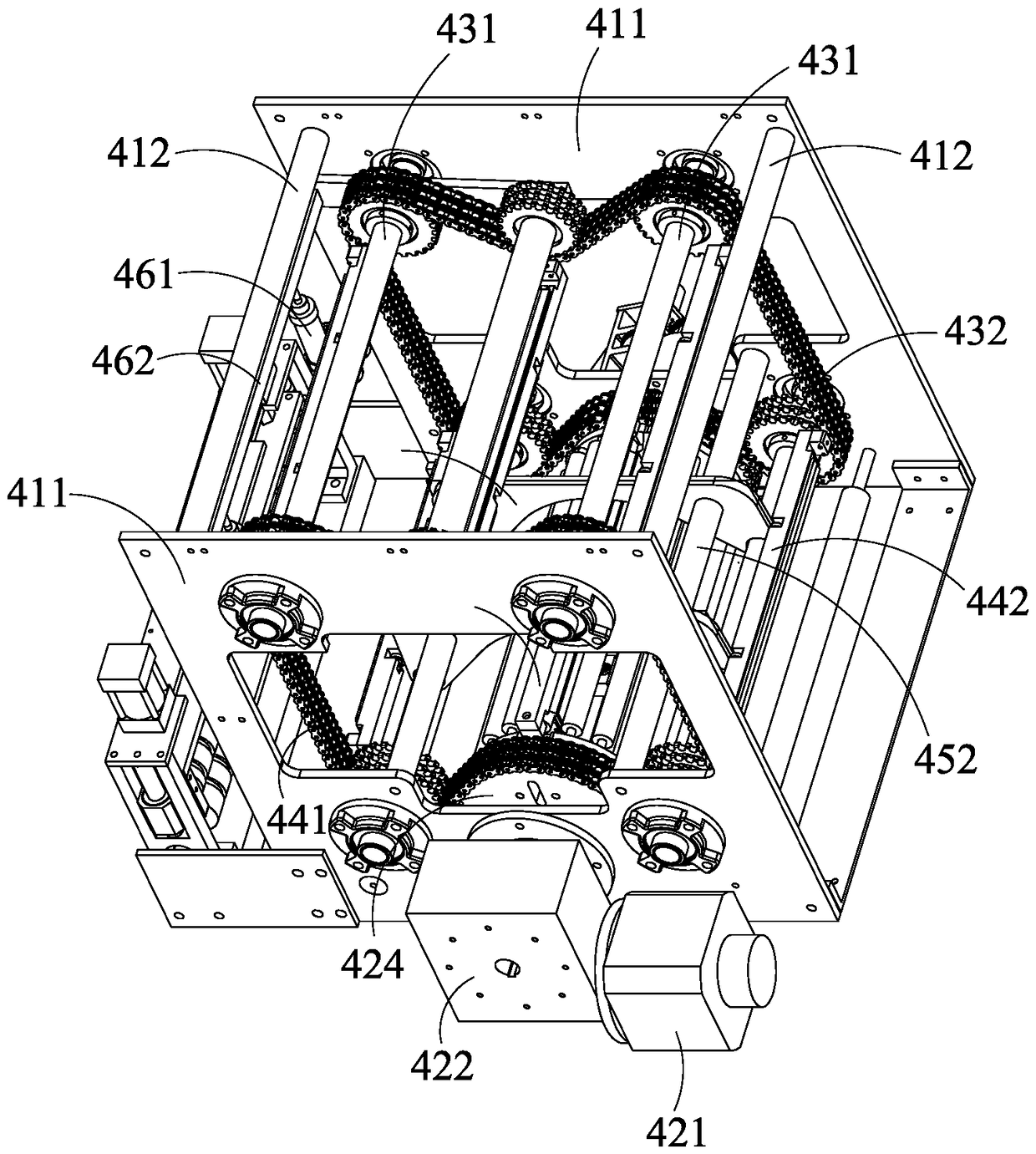

[0037] Such as Figure 1 to Figure 14 As shown, the present invention discloses a production equipment for plastic vest bags, which includes an active feeding mechanism 1, a film tensioning mechanism 2, a feeding mechanism 3, a synchronous heat sealing mechanism 4, a printing color tracking mechanism 5, and a die-cutting mechanism 6. Bag-folding mechanism 7, feeder beating mechanism 8, feeder rewinding mechanism 9.

[0038]The above-mentioned active feeding mechanism 1, film tensioning mechanism 2, feeding mechanism 3, synchronous heat sealing mechanism 4, printing color tracking mechanism 5, die-cutting mechanism 6, bag folding mechanism 7, material head feeding mechanism 8, material head receiving The roll mechanism 9 is arranged into different stations according to the production process. Specifically, the active feeding mechanism 1 is arranged in front of the feeding mechanism 3, and the film tensioning mechanism 2 is arranged between the active discharging mechanism 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com