Automatic electrolytic cell liquid level adjusting device

An automatic adjustment, electrolytic cell technology, applied in the direction of electrolysis process, electrolysis components, photography process, etc., can solve the problems of electrolyte loss, electrolyte concentration change, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

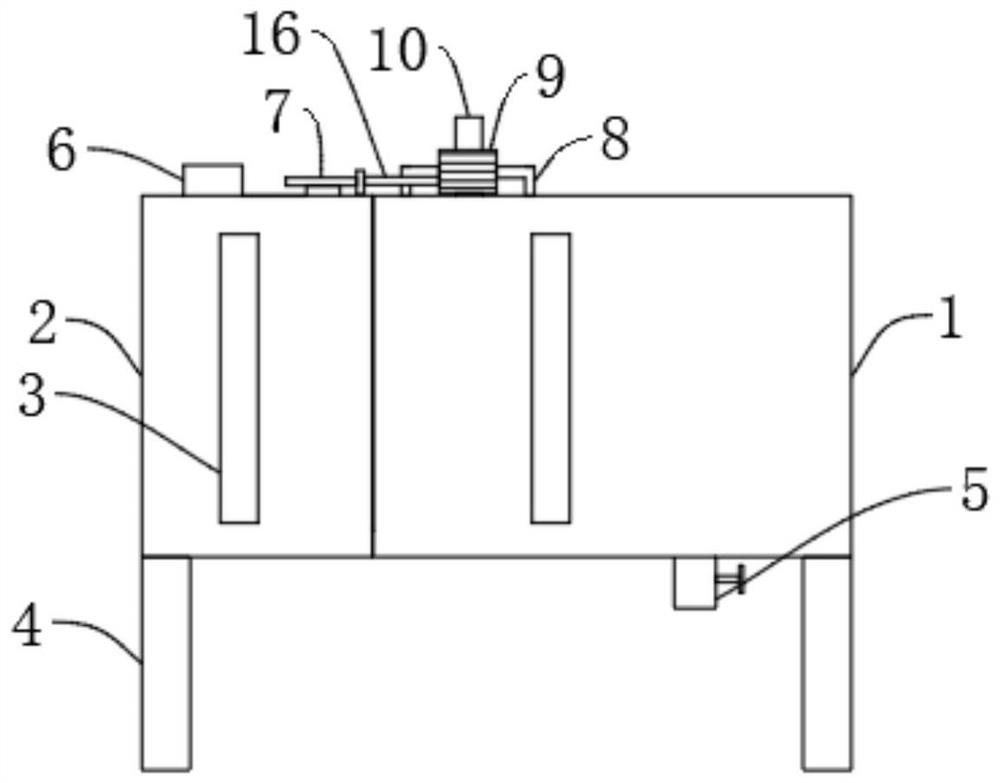

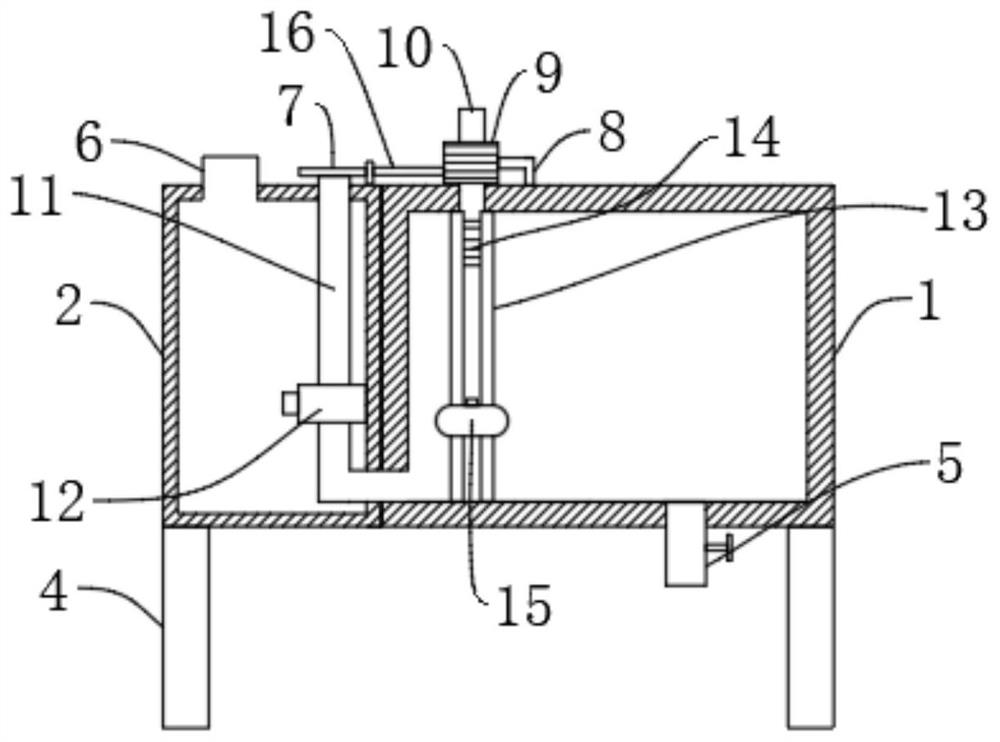

[0027] Embodiment one, by figure 1 , figure 2 and image 3 Provided, the present invention is an electrolytic cell liquid level automatic adjustment device, comprising an electrolytic cell 1, the left side of the electrolytic cell 1 is fixedly connected with a supplementary liquid tank 2, and the inner cavity of the supplementary liquid tank 2 is fixedly connected with a water pipe 11, and the water pipe 11 is connected to the electrolytic cell 1 is connected, the surface of the water pipe 11 is clamped with the water pump 12, the top of the water pipe 11 is fixedly connected with the switch 7, the rear surface of the inner wall of the electrolytic cell 1 is slidingly connected with the expansion plate 10, the surface of the expansion plate 10 is fixedly connected with the rack 14, and the bottom of the expansion plate 10 The buoy 15 is clamped, the top of the electrolytic cell 1 is provided with a gear 9, the gear 9 meshes with the rack 14, the left side of the gear 9 is fi...

Embodiment 2

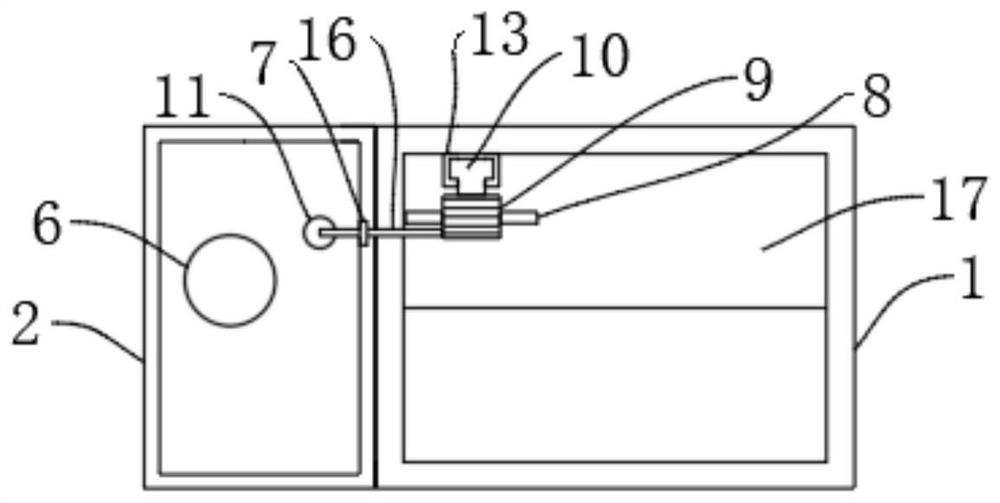

[0028] Embodiment two, on the basis of embodiment one, by image 3 Given, the surface of the electrolytic cell 1 is clamped with a support plate 17 , the surface of the support plate 17 is fixedly connected with a fixed rod 8 , the fixed rod 8 is in an inverted U shape, and the fixed rod 8 is rotatably connected with the gear 9 .

[0029] The support plate 17 is designed to support the fixed rod 8, and the fixed rod 8 is designed to install the gear 9 to facilitate its rotation.

Embodiment 3

[0030] Embodiment three, on the basis of embodiment one, by figure 2 Given, the rear side of the inner wall of the electrolytic cell 1 is fixedly connected with a fixed block 13, the surface of the fixed block 13 is provided with a chute, the chute is T-shaped, and the telescopic plate 10 is slidably connected to the inner cavity of the chute, and the material of the telescopic plate 10 is light plastic.

[0031] The design of the chute is convenient for the telescopic plate 10 to slide, and the material of the telescopic plate 10 is light plastic so that the telescopic plate 10 can expand and contract with the buoyancy of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com