Grinding machine for optical fiber cable manufacturing

A fiber optic cable and grinding machine technology, which is applied in the direction of grinding machine tools, grinding devices, manufacturing tools, etc., can solve the problems of affecting the working environment, flying and putting in grinding residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

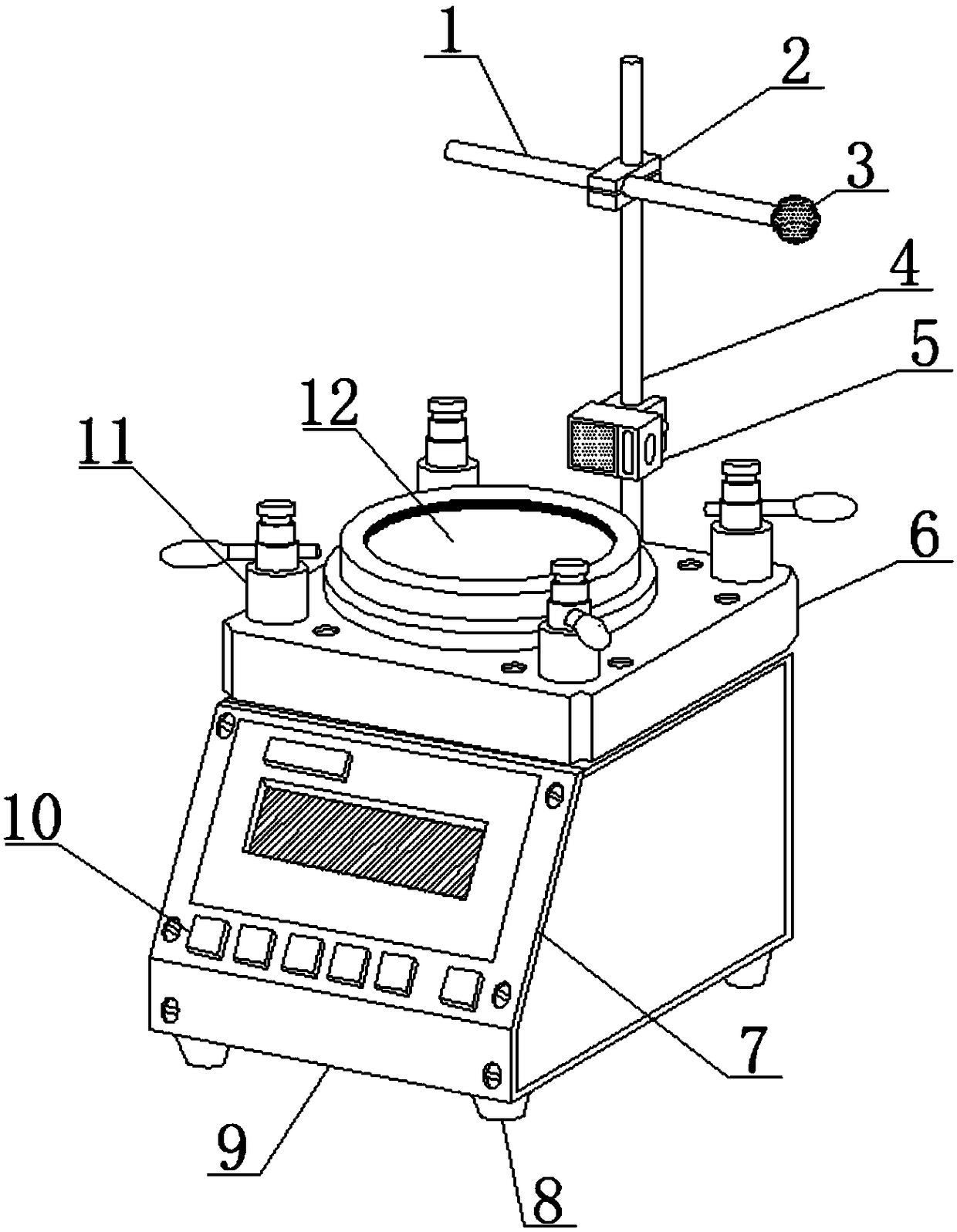

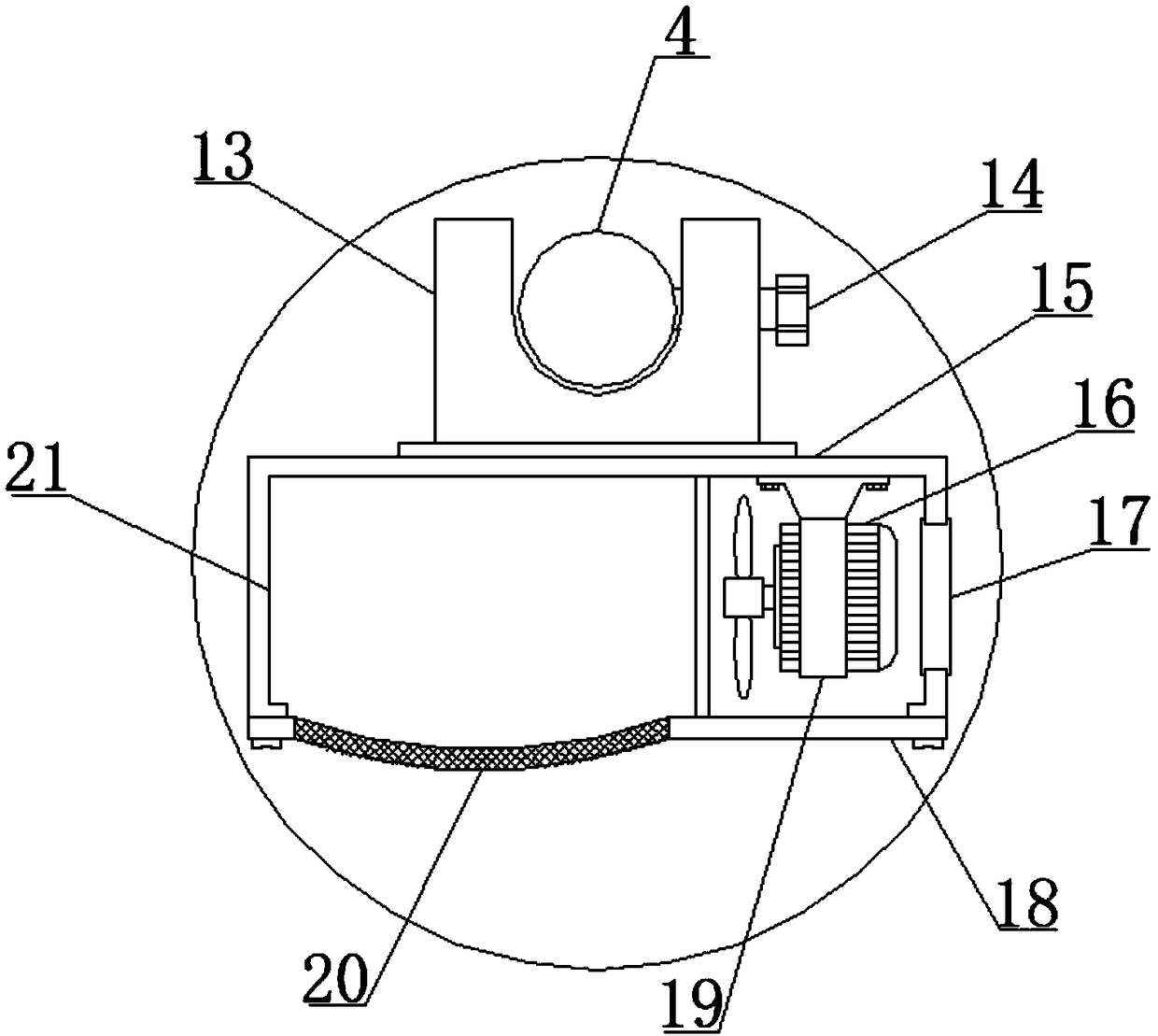

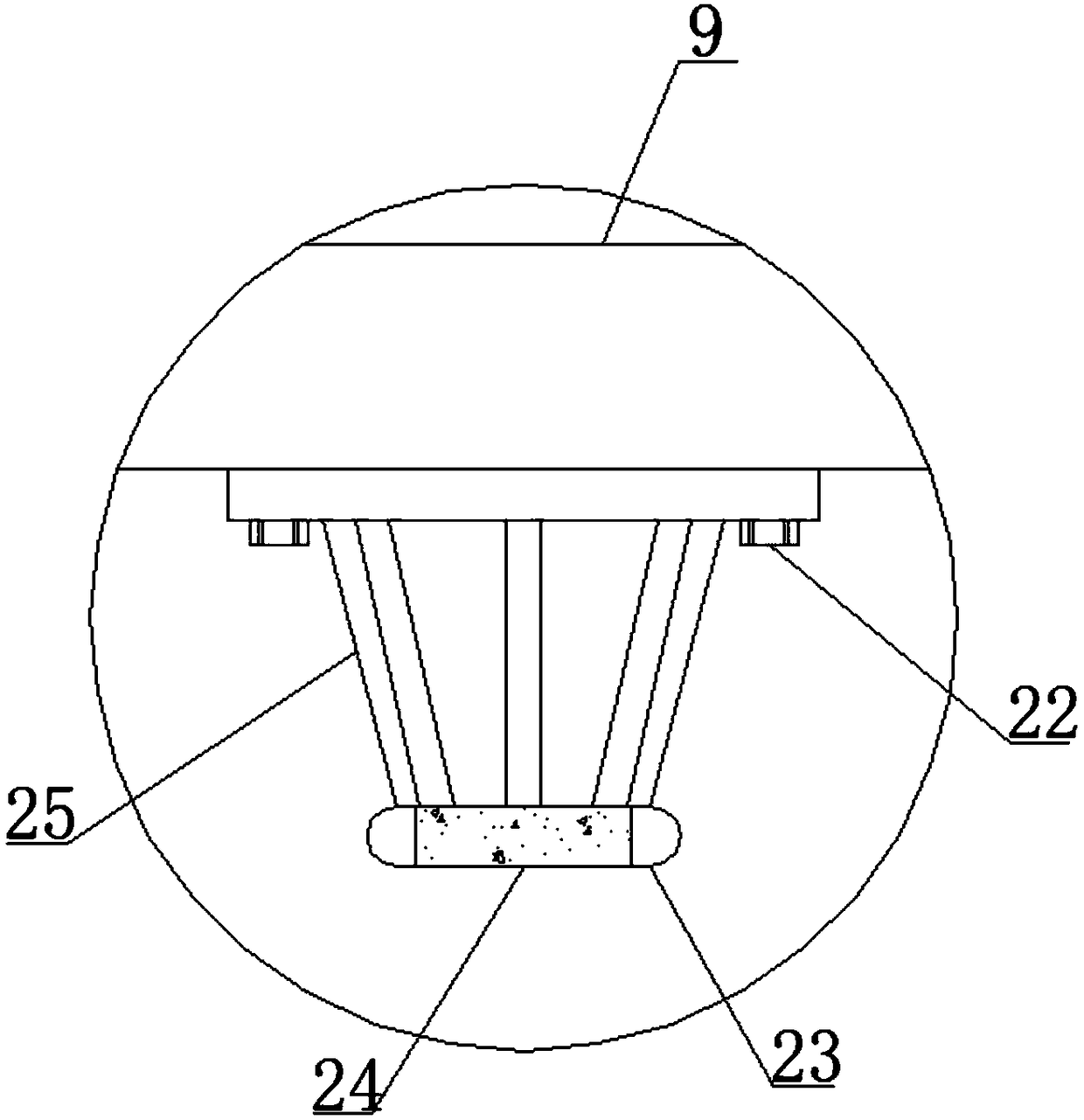

[0029] Such as Figure 1-Figure 6 As shown, a grinding machine for optical fiber cable manufacturing includes a magnetic support 8, the magnetic support 8 is installed at the four corners of the lower end of the body 9, the front of the body 9 is fixed with an end face 7 by a nut, and the end face 7 is relative to the position of the body 9. The other side is provided with a control switch 10, the upper end of the body 9 is provided with a grinding table 6, the upper center of the grinding table 6 is provided with a grinding turntable 12, and the four corners of the upper end of the grinding table 6 are provided with fixing devices around the grinding turntable 12. 11. There is a vertical rod 4 directly behind the body 9 and the grinding table 6, and the vertical rod 4 is fixed on the body 9. The middle position of the vertical rod 4 is buckled with a dust suction device 5, and the position in front of the upper end of the vertical rod 4 is A cross bar 1 is provided, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com