Dust fall system for cantilever type heading machine

A cantilever type, roadheader technology, which is applied in the direction of slitting machinery, earth-moving drilling and mining, etc., can solve the problems of difficult on-site implementation, high air viscosity, and difficulty in advancing, and achieves broad market application prospects, avoiding diffusion, and improving dust removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

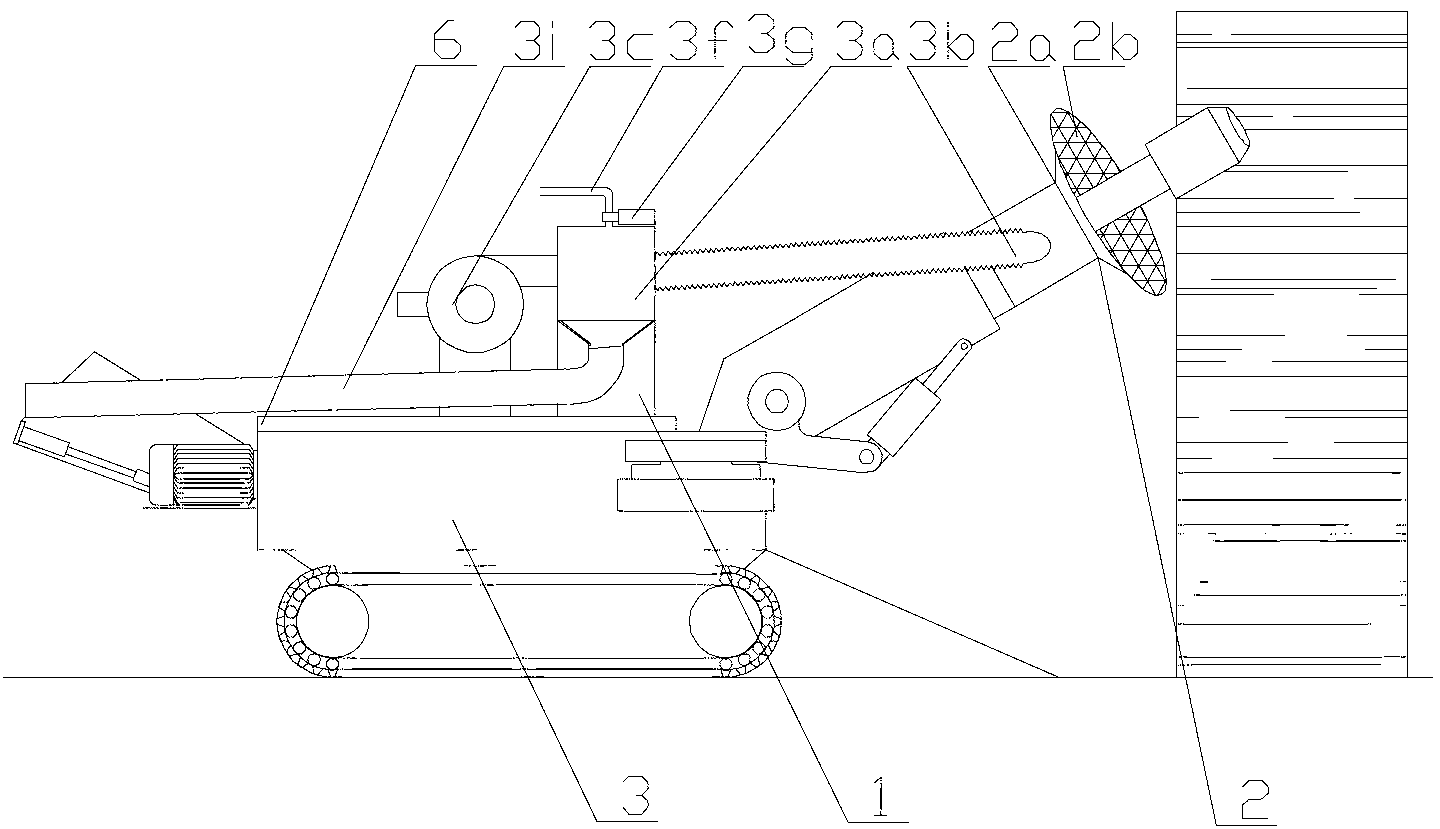

[0020] see figure 1 , a cantilever type roadheader dust suppression system provided by the present invention includes a mine dust collection mechanism 2 and a mine dust treatment mechanism 3 installed on the roadheader body 1,

[0021] The mine dust collection mechanism 2 includes an umbrella-shaped dust collection cover 2a sleeved on the cutting arm of the roadheader, and a rock filter screen 2b is installed in the umbrella-shaped dust collection cover 2a; in order to increase the dust removal effect, the dust collection cover is not Under the premise of affecting the work of the roadheader, it should be as close as possible to the cutting head. Because the rock filter 2b is close to the cutting head, it is easy to be damaged and needs to be replaced regularly. Therefore, the filter is designed to be easy to disassemble.

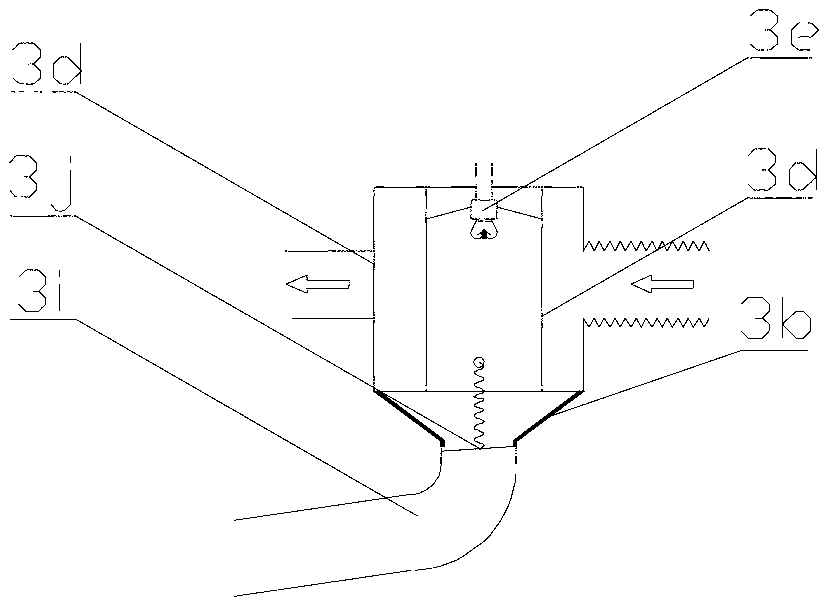

[0022] The mine dust processing mechanism 3 includes a dust reduction box 3a, and a dust suction pipe 3b communicating with it is transversely penetrated i...

Embodiment 2

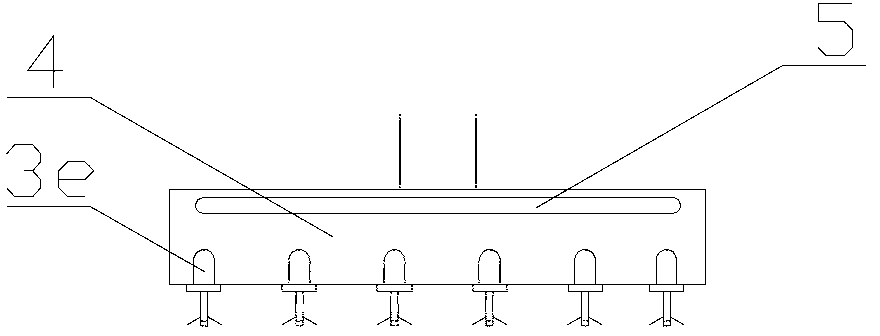

[0025] see image 3 , the water mist nozzles 3e are uniformly arranged in the nozzle groove 4 communicating with the water inlet pipe 3f, and a diversion groove 5 is provided at the junction of the nozzle groove 4 top and the water inlet end of the water inlet pipe 3f. The two ends of the groove 5 are in contact with the dust filter 3d respectively, and are used to wash away the powder mud adhered to the filter.

Embodiment 3

[0027] The dust suction pipe 3b adopts a flexible plastic hose structure, and the number is recommended to be designed as two or more groups to improve the dust collection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com