Use method of safe-to-operate distillation device for duck fat preparation

A technology of safe operation and distillation equipment, which is applied in the field of distillation equipment for duck oil preparation, can solve the problems of poor treatment effect of floating oil, influence of distillation effect, and adhesion on the surface of raw liquid, etc., to facilitate subsequent use, avoid oil condensation, control The effect of fat solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

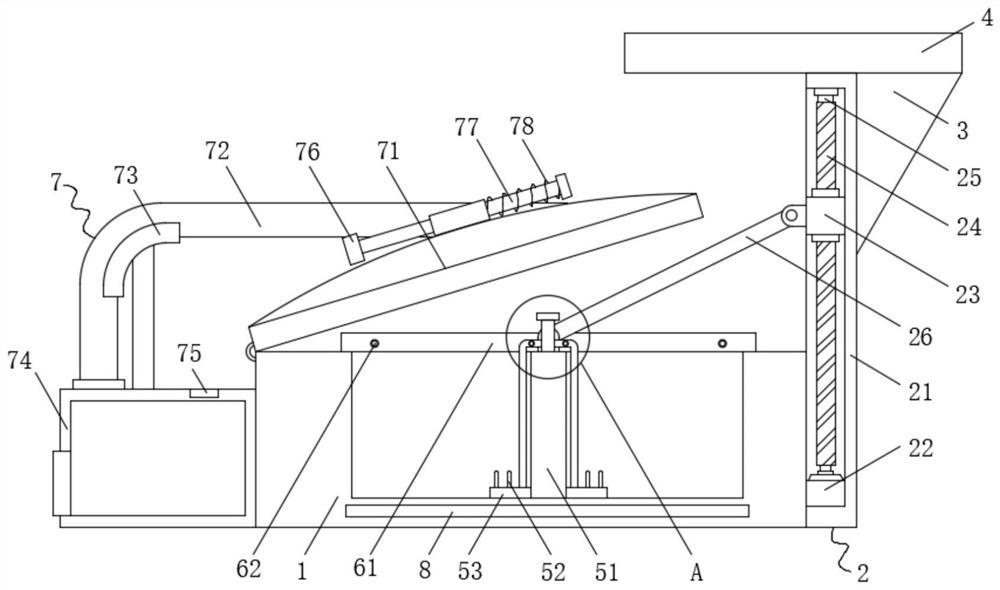

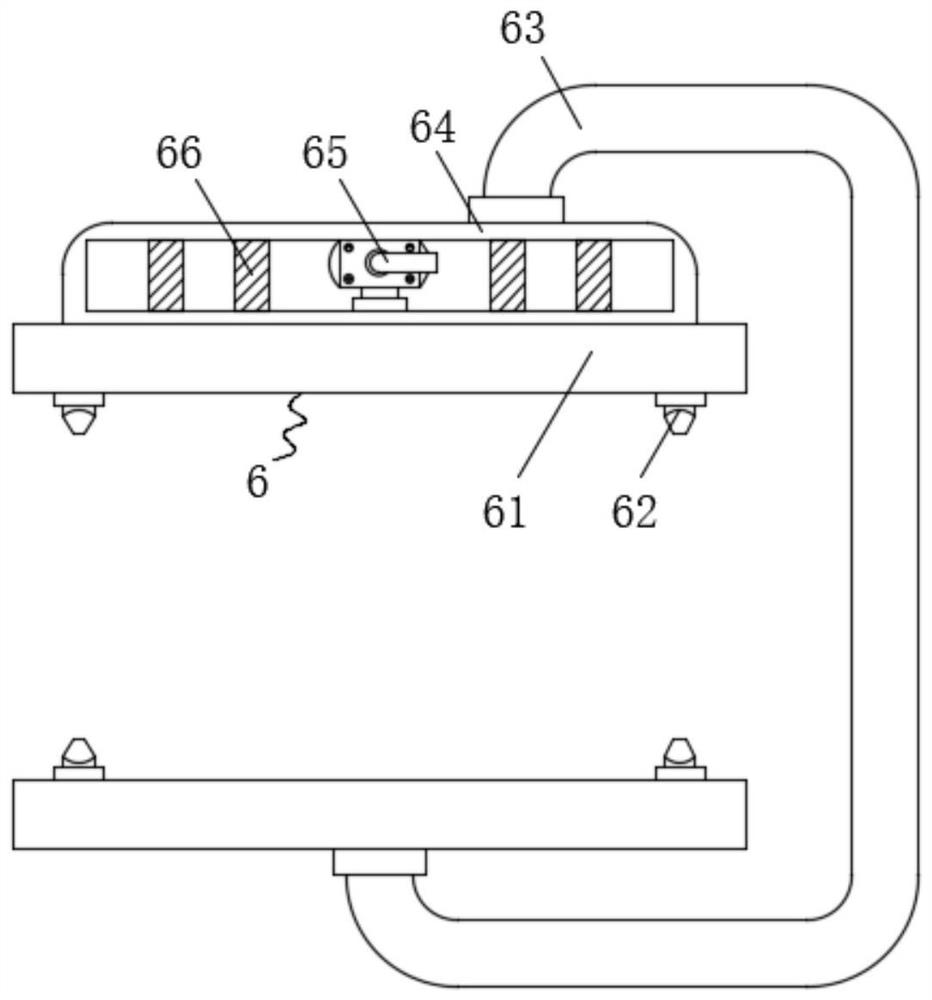

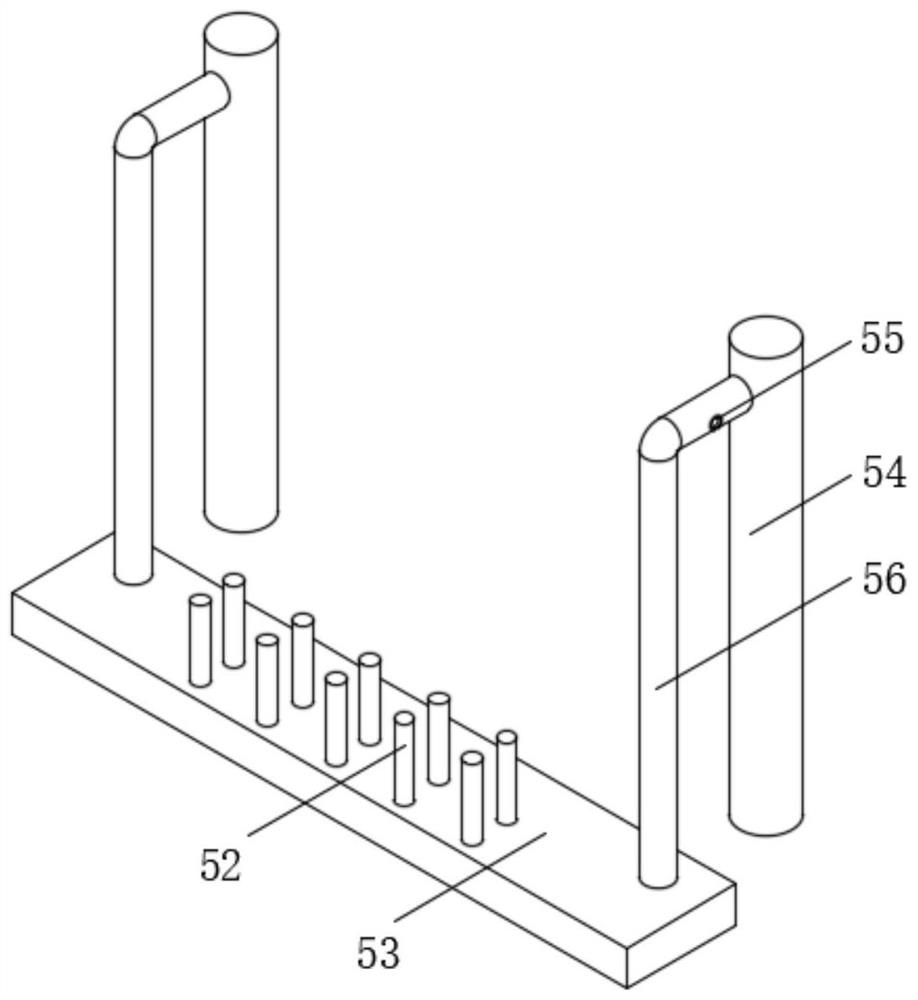

[0038] The specific implementation method is: through the driving mechanism 2, the motor 22 can drive the reciprocating screw 24 to rotate when it works, and the screw cap can drive the slider 23 to move up and down, and the slider 23 moves up and down to drive one end of the connecting rod 26 to move up and down, and The other end of the connecting rod 26 can drive the oil scraping mechanism 5 to move left and right. At this time, the oil scraping mechanism 5 can effectively scrape off the grease floating on the liquid surface and push it to both sides without affecting the normal distillation of the stock solution.

[0039] The top of the driving mechanism 2 is fixedly connected with a blower refrigeration mechanism 4, and the blast refrigeration mechanism 4 includes a casing 48 fixedly connected to the upper surface of the side plate 21, and a second rotating shaft 41 is rotatably connected in the casing 48, and the second rotating shaft 41 The bottom end is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com