Gas boiler with tail gas heat convenient to absorb and store

A gas-fired boiler and heat technology, which is applied in the field of boiler combustion, can solve the problems of affecting the working environment of the workshop and insufficient cleaning of solid particles, and achieve the effects of improving the dust reduction effect, reducing the waste of heat, and improving the cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

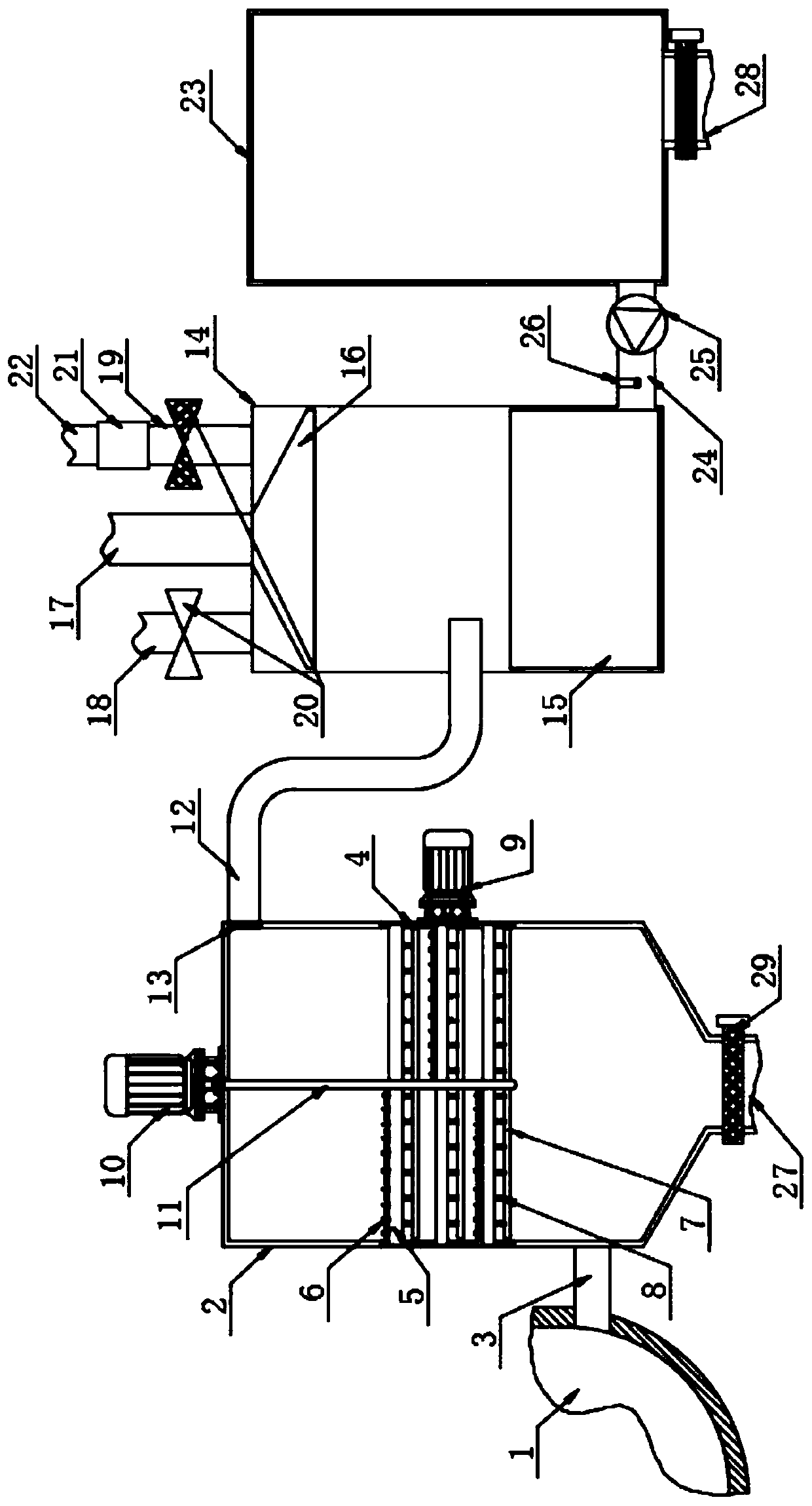

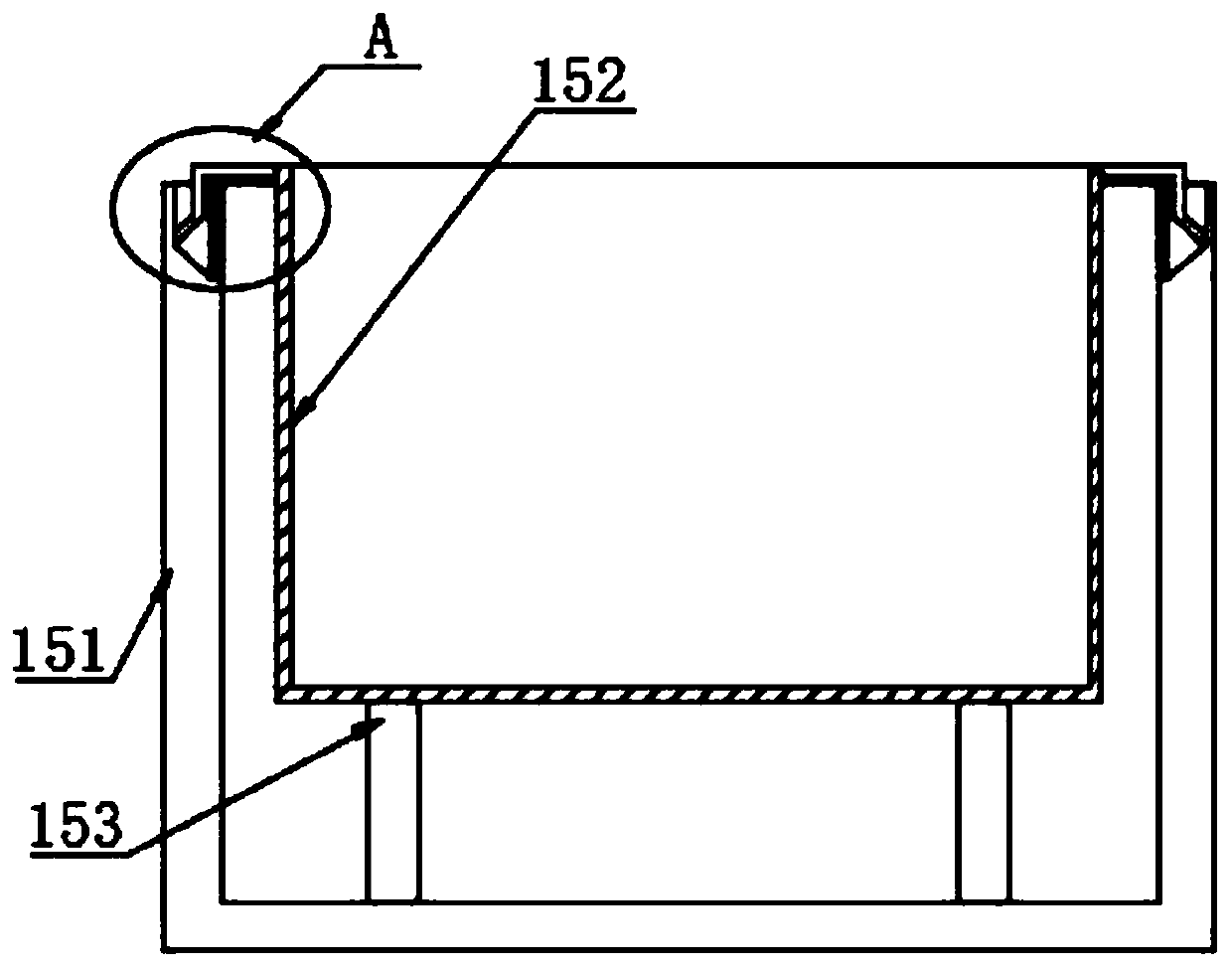

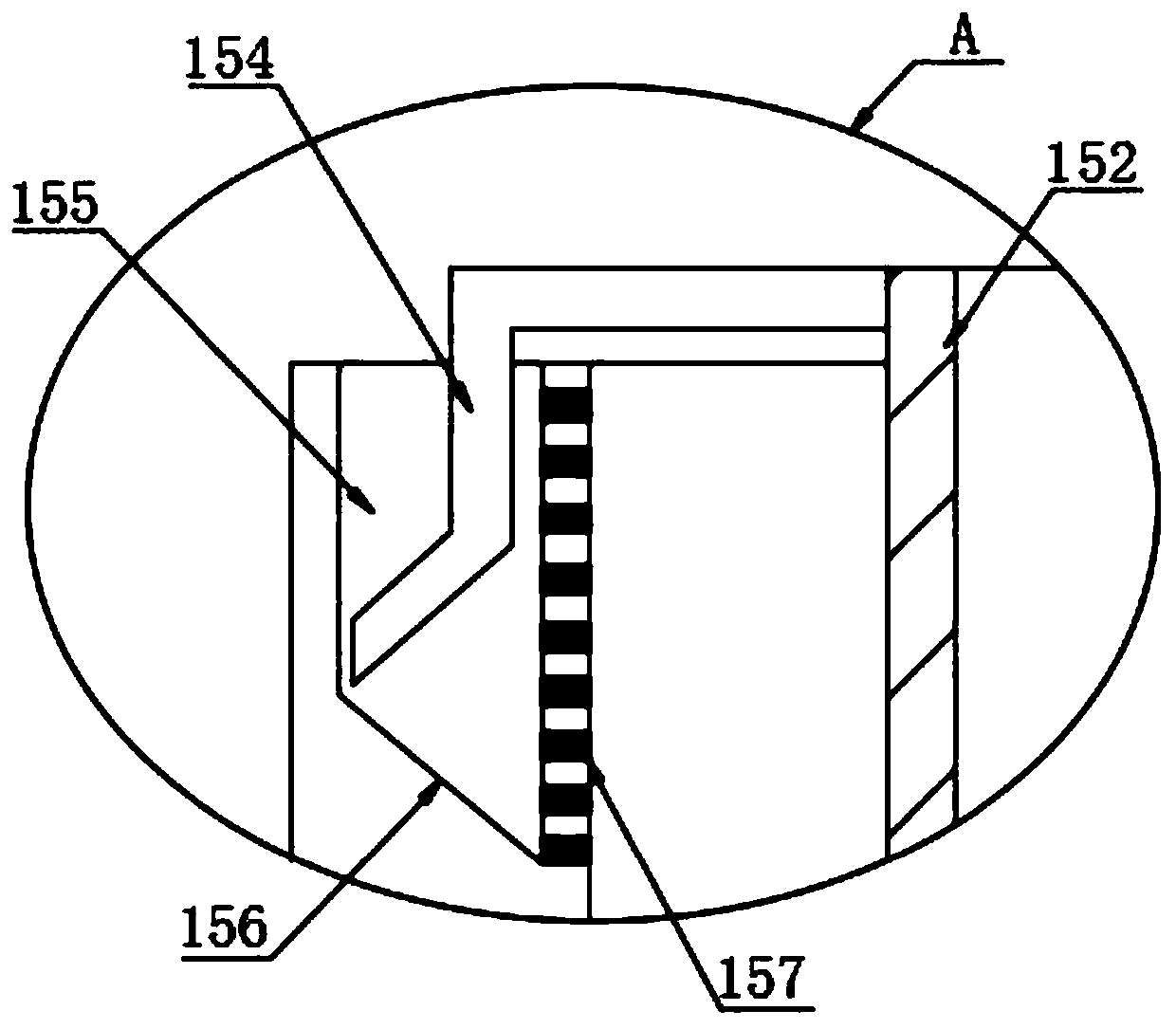

[0027] The present invention provides such Figure 1-8The gas boiler shown is convenient for absorbing and storing the heat of exhaust gas, including a gas boiler furnace body 1, a filter box 2 is arranged on one side of the gas boiler furnace body 1, and a filter box 2 is arranged between the gas boiler furnace body 1 and the filter box 2 There is a first air pipe 3, and the two are connected through the first air pipe 3, the middle part of the filter box 2 is fixedly provided with a collar 4, and the inner wall of the circumferential side of the collar 4 is fixedly provided with a filter screen 5, the The top of the filter screen 5 is provided with a brush rod 6 and the bottom is provided with a vibration transmission rod 7, the side of the vibration transmission rod 7 facing the filter screen 5 is vertically provided with a contact rod 8, and one end of the vibration transmission rod 7 is fixed to the inner wall of the collar 4 Connected, the outer middle part of the collar...

Embodiment 2

[0036] Different from the embodiment, the top of the filter box 2 is provided with a fitting groove 34, and the inside of the fitting groove 34 is equipped with a second cover plate 35, and the first activated carbon adsorption plate 13 is movably inserted into the second cover The bottom of the plate 35, the top of the second air pipe 12 corresponding to the bottom of the second cover plate 35 is provided with a semi-annular groove 37, and the bottom of the first activated carbon adsorption plate 13 is movably inserted in the semi-annular groove 37, and is connected with The inner cavity of the second gas delivery pipe 12 is matched, and the second cover plate 35 is fixedly connected with the filter box 2 by screws, which is beneficial to remove the second cover plate 35 after using for a period of time, and can realize the cleaning of the first activated carbon. The adsorption plate 13 is replaced and cleaned, thereby improving the exhaust gas treatment effect. The end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com